CASE STUDY

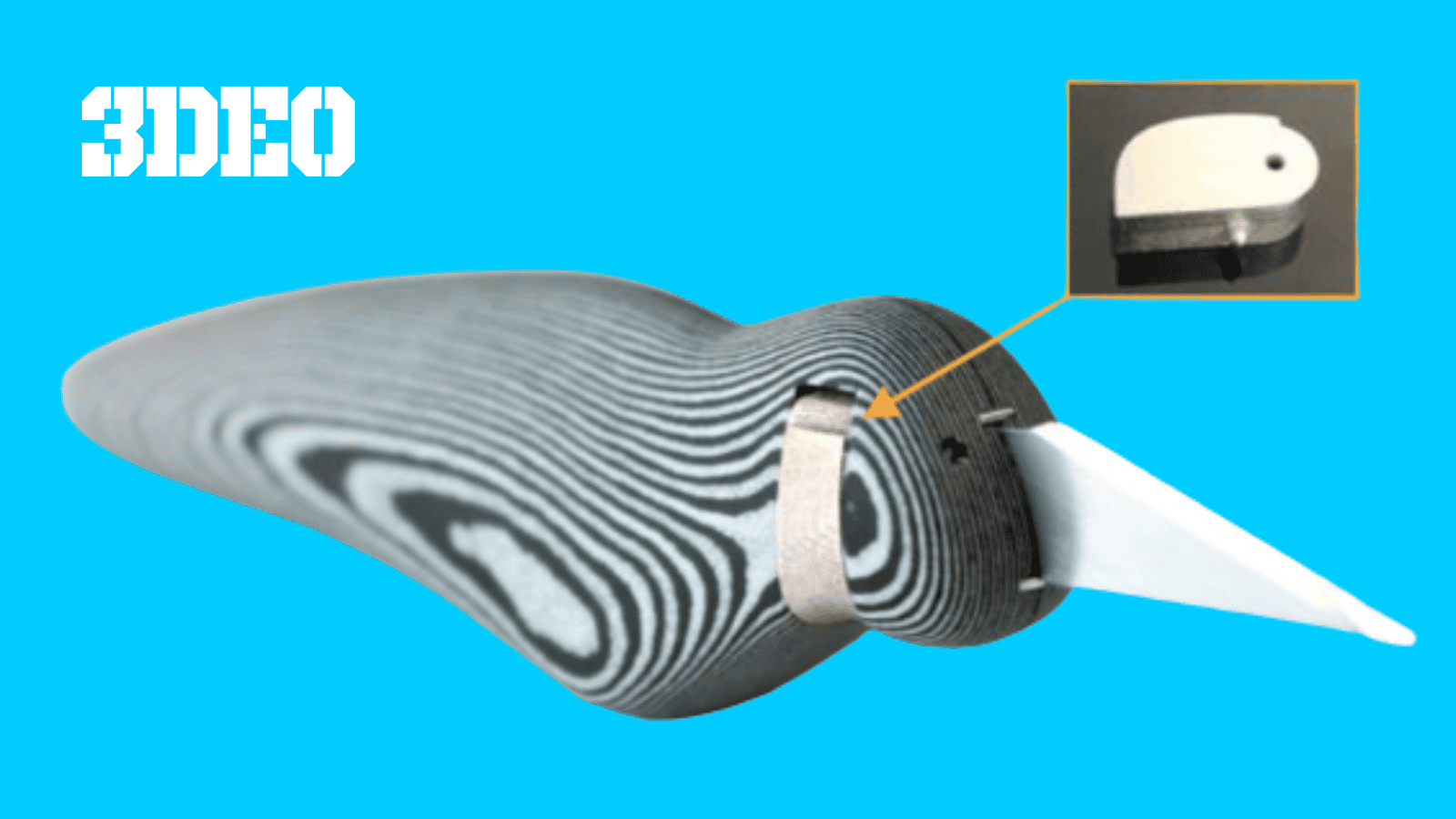

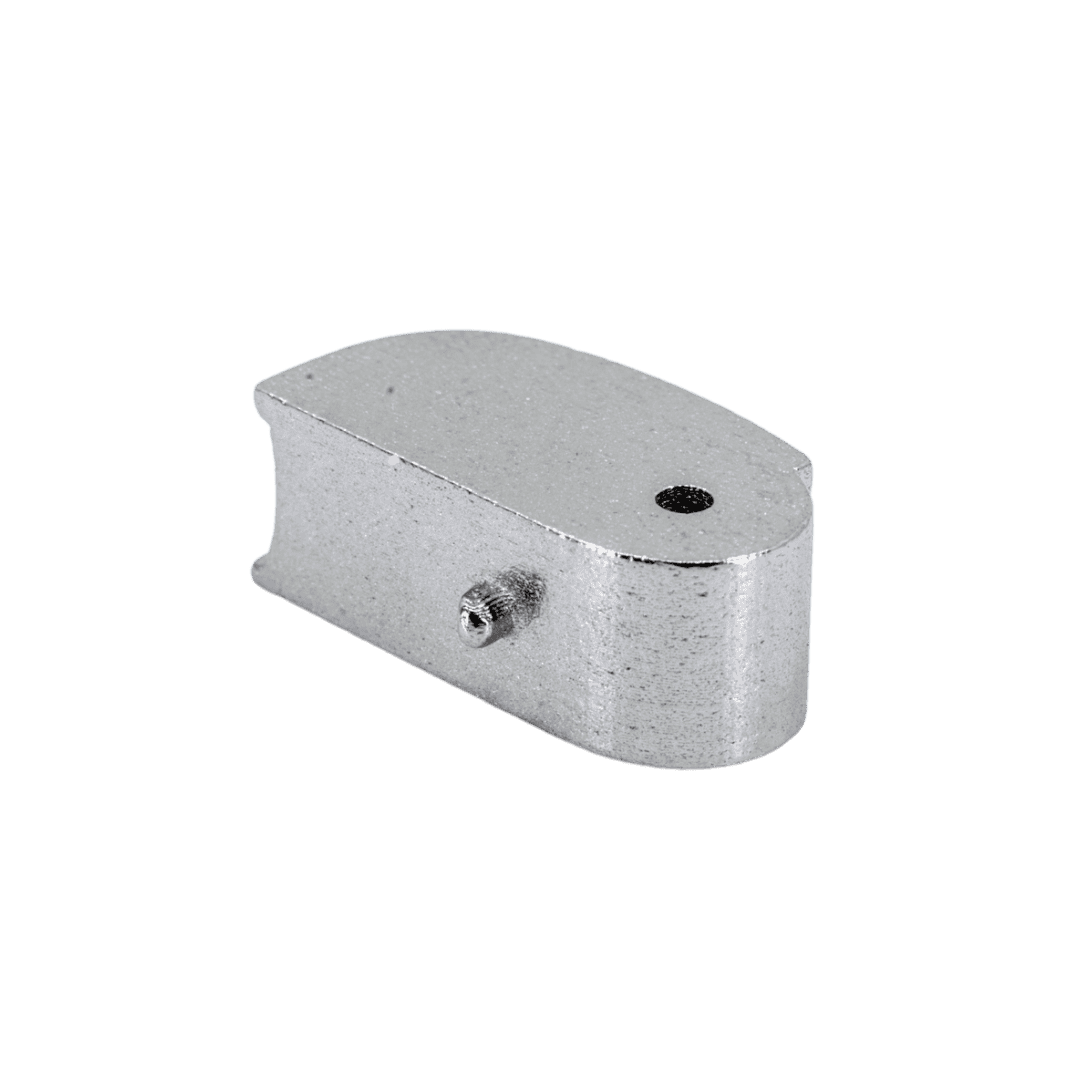

Latch for Cutting Tool

3DEO’s Latch Part

Customer: Ergokiwi

ErgoKiwi wanted to utilize metal 3D printing for a latch used in their ergonomic cutting tool. They were underwhelmed by the visual quality of another metal 3D printing service, so they came to 3DEO for help. According to ErgoKiwi, the new finish dramatically improved the final product.

Ergokiwi's Problem

ErgoKiwi was a crowdfunded startup that did not want to pay the high startup costs of traditional manufacturing processes and hoped to find an on-demand manufacturing, low-cost alternative. ErgoKiwi was disappointed by the quality and surface of binder jetting and the high cost of DMLS.

3DEO's Solution

ErgoKiwi found metal 3D printing could be a great way to solve the problem of up-front costs by eliminating tooling/setup costs. 3DEO delivered parts that left ErgoKiwi “blown away” by the quality and surface finish, all while beating the cost of the other metal 3D printing service.

”I’ve searched far and wide and 3DEO is the only place I will go to get my prints done.

Co-Founder of ErgoKiwi

Cameron Chateauneuf

Interview with Cameron Chateauneuf, Co-Founder of ErgoKiwi

Why Metal 3D Printing?

We went with 3D printing because we can come up with slight variations on the design and make modifications. Also, we learned that 3DEO could print our part to one-thousandths of an inch.

Why Switch From CNC Machining?

We use CNC for everything we make, but it’s not right for our metal latches. The tolerances required are very high.

How Was the Transition to 3D?

The process was simple. I sent a model for 3DEO to review, then they sent a couple of samples and we’re on the road.

Why Purchase from 3DEO?

If I wanted to buy myself a metal 3D printer for $50,000, it wouldn’t cut it. I was looking for someone that could do exactly what they do. I promise I’ve looked everywhere, and 3DEO is the best you’re going to find.