Article by 3DPrint.com. Read the full article here.

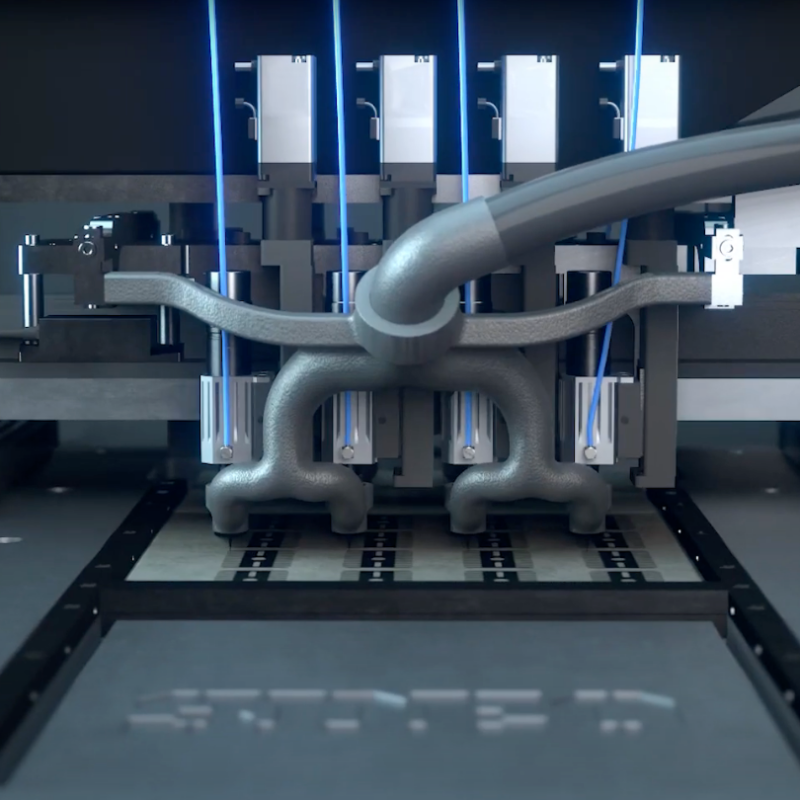

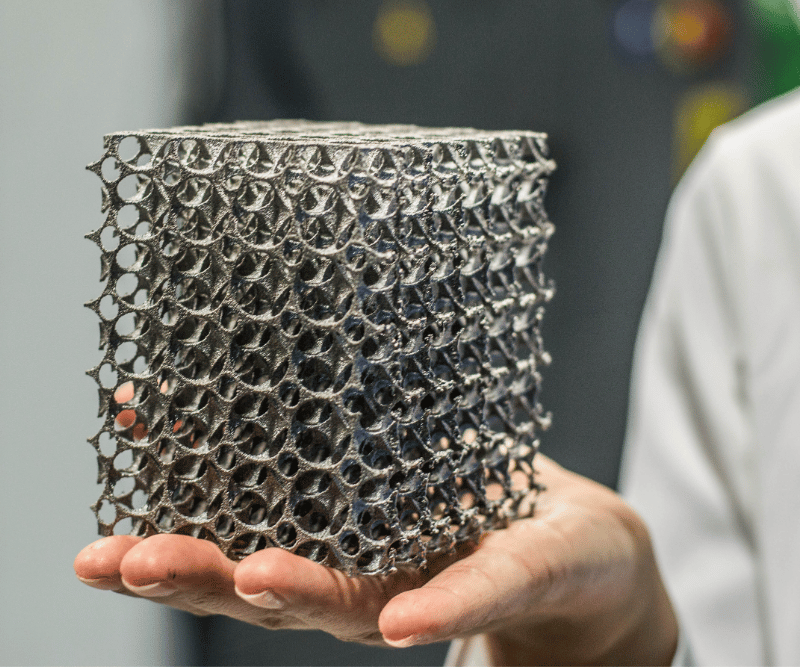

California-based 3DEO is a unique firm. Among the first to offer a proprietary metal 3D printing solution as a service, 3DEO has since been followed by the likes of Seurat, VulcanForms, and FreeForm. Unlike those companies, which rely on lasers, 3DEO has developed a technique called Intelligent Layering, in which a thin layer of metal powder is spread across a bed before a binder is sprayed with across the entire build area. A CNC mill then traces the outline of the part and any internal features. The completed green-state object is sintered in a furnace to achieve full density.

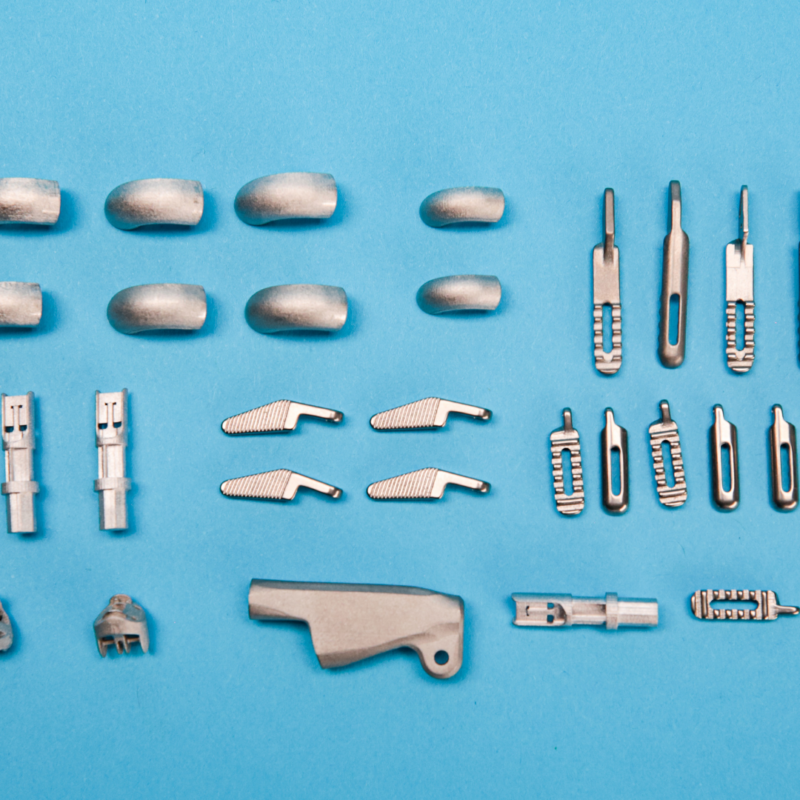

The latest development from the company is the addition of pure copper to its materials portfolio. I was able to speak to Jonathan Kolodner, Director of Applications Engineering & Design, to learn more.

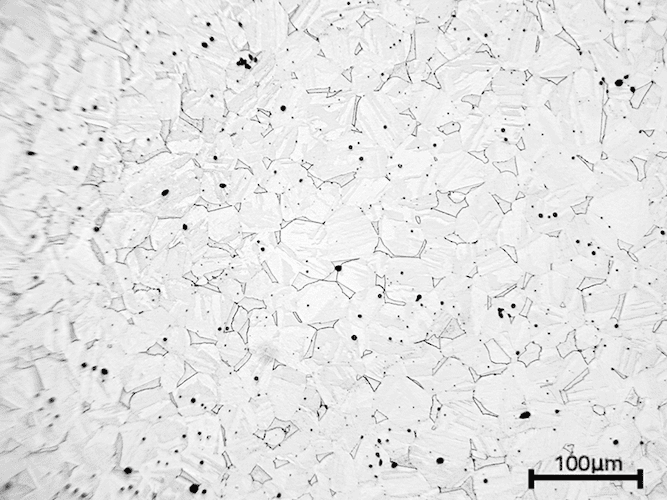

“We’ve got a high density and a low oxygen content, which is great. [At RAPID + TCT 2023, we] had a lot of people coming by and saying, are you really achieving that level of purity?”

Kolodner was referring to the listed oxygen content of <0.005, which is “critical for conductivity.” 3DEO is using copper for thermal management, like heat exchangers, along with other applications as well.

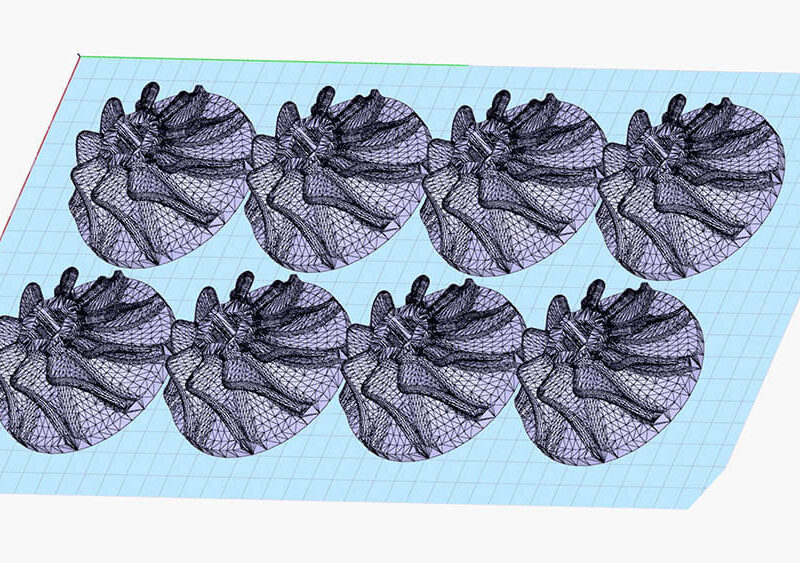

“We’re really working on fine tuning our ability to do internal geometries for parts in copper. Our print area for it allows us to do a lot of applications for the semiconductor industry. And we’re looking at electric vehicles, as well.”

3DEO works closely with its customers to create “a tailored solution that works for their form factor and footprint that they need, but in our technology.”

“Critically, it’s replacing a traditional manufacturing process that has a 20 week lead time with one that has a four-week lead time,” he explained. “And we’re looking at interesting applications where we can integrate features that traditional manufacturing can’t provide.”

Kolodner said in thermal management, copper is often made into tubing or constrained spaces for heat pipes. 3DEO can achieve this, and also add features that traditional manufacturing processes can’t, as well as offer a lower price point. That’s because 3DEO’s process works “from a less rigorously controlled powder requirement because we don’t have the same performance that the laser-based processes have.”

“It allows us to process at a lower price point per unit, which is economically advantageous when you want to go to scale. If you’re making a rocket nozzle and you only need one, the fact that the material’s twice as much is not the end of the world. But if you’re making thousands or hundreds of thousands of a part, you need it to have a good economic profile.”

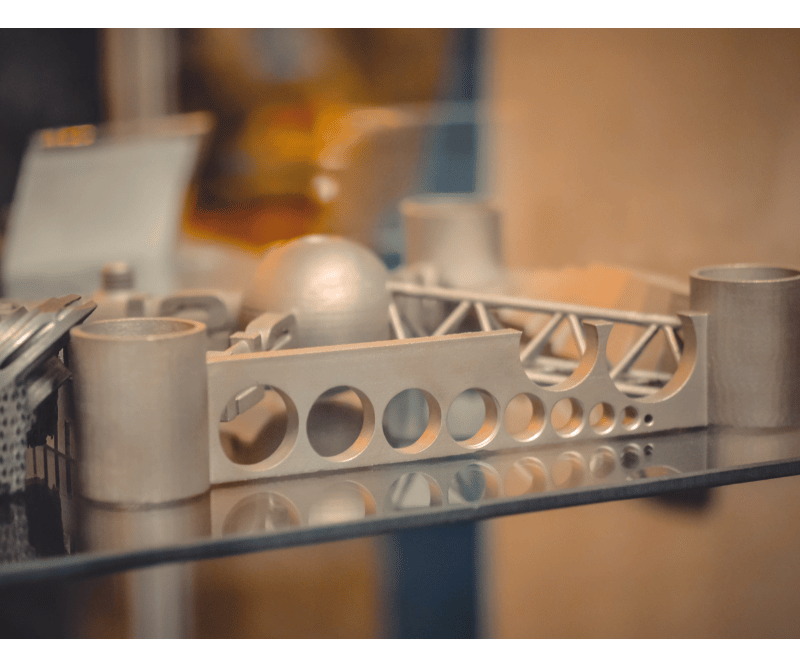

I wasn’t allowed to take any pictures of the copper 3D printed heat exchanger, but Kolodner showed me a smaller version, made out of a different metal, that’s being used to test how fine they can make the features for the larger, copper version.

Applying DfAM Services to Rail

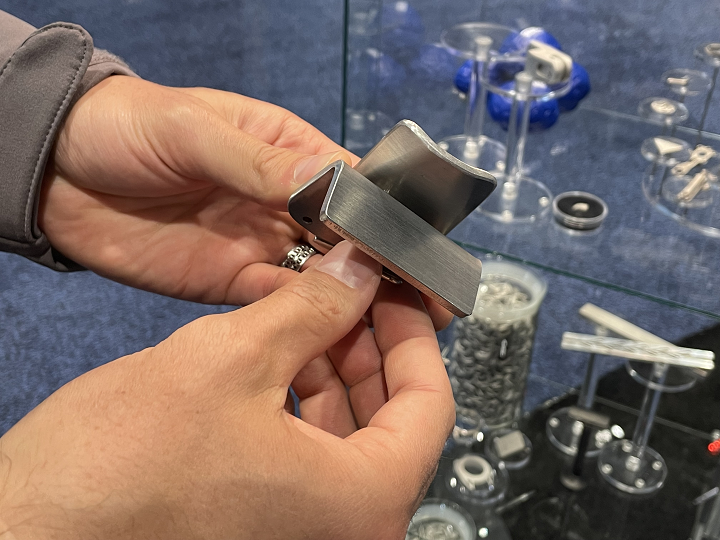

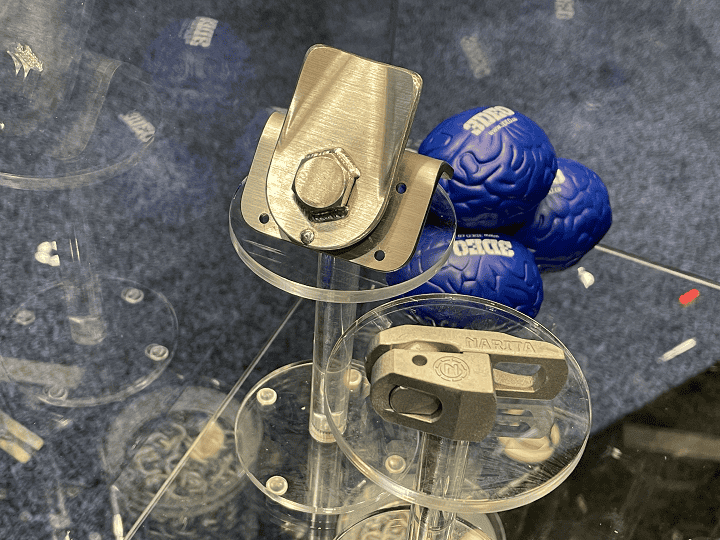

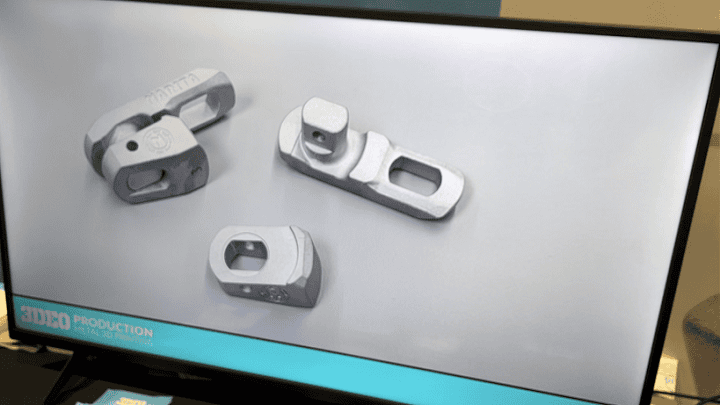

Kolodner showed me a heavy industry project the team did last year for a railcar inter-car baffle, which originally had several parts and not enough resistance to turning without a tool.

“You don’t want some teenager undoing the baffle on a bullet train. That’s a bad idea!”

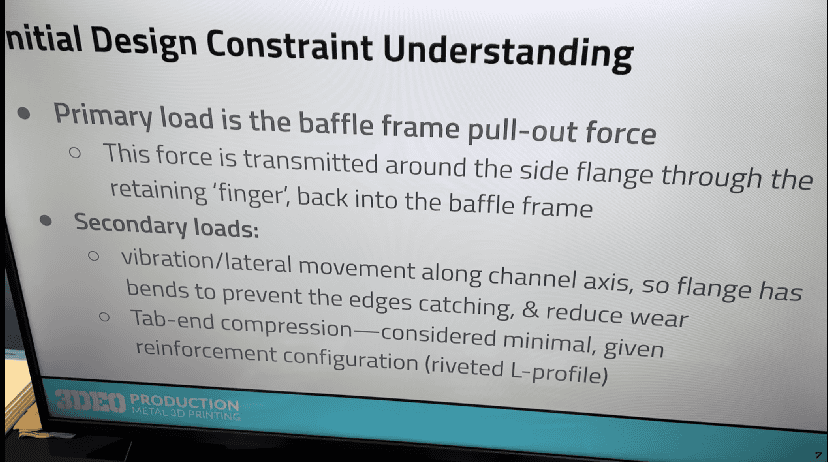

Kolodner explained the ideation process with customers—3DEO asks about the “derived requirements,” initial design constraints, and then determines with the customer how “additive as a process” is “optimally suited for the job to be done.”

In this instance, the customer sent pictures of the original part and how it’s configured on the railway car, which gave 3DEO a better understanding of its operation. Then the team asked some questions about it, such as how often, if ever, the assembly is completely removed, and how much necessary turn resistance there should be for the baffle’s installation and removal.

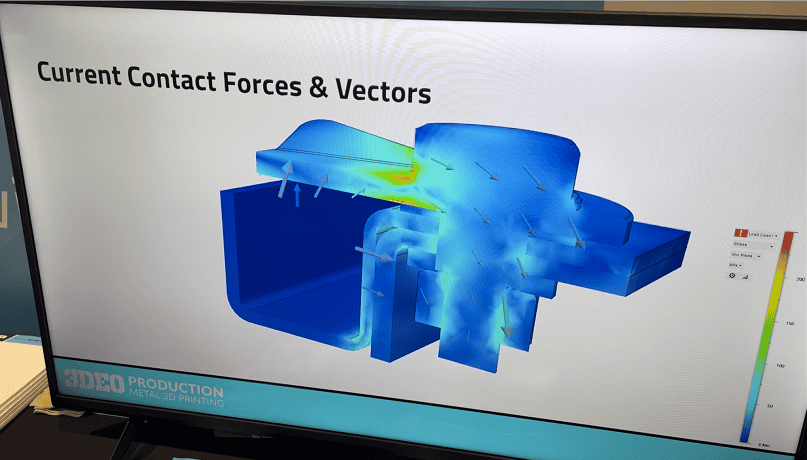

“But really the opportunities that stood out to me were…you have all these different processes going on. You’ve got bent sheet metal, you’ve got grinding, you’ve got welding, you’ve got riveting. All of that stuff takes time, labor and skill. So I started doing some simulation-driven design, figuring out how the existing design works in order to achieve the job it’s achieving, and how do we then think about the constraints of printing and what shape the part should take in order to be reflective of our process in meeting that job.”

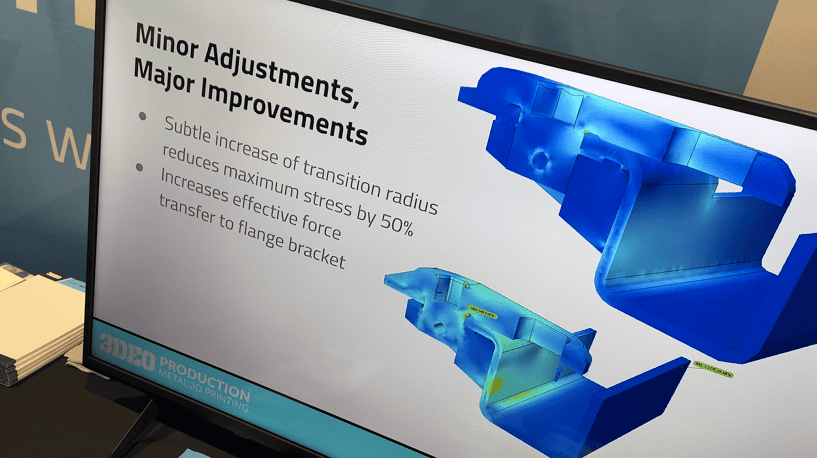

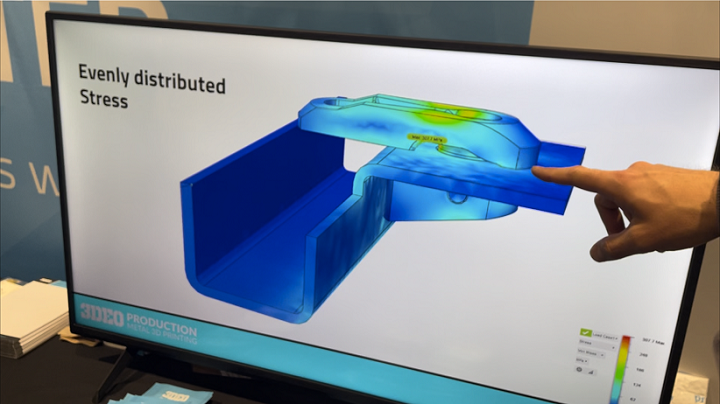

3DEO used simulation to better understand how the stresses were distributed in the existing part, and how to revise the assembly for the new part to redirect force.

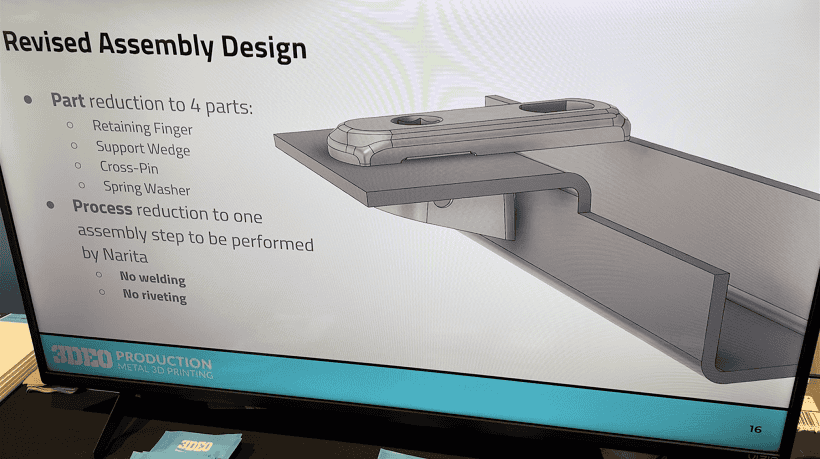

“So then we can reduce all the processes and we can reduce the parts way down,” Kolodner said.

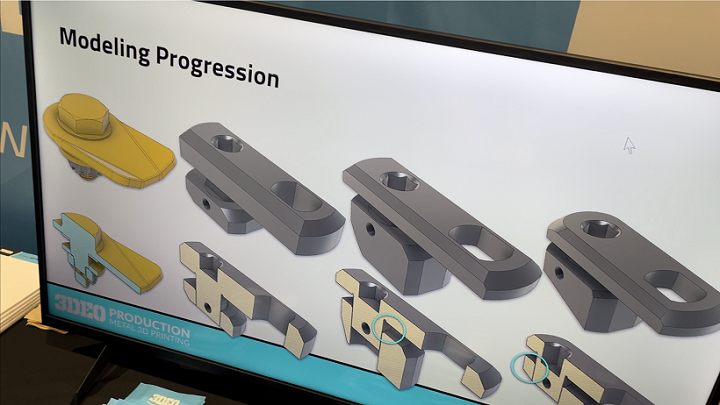

But, there were still many iterations of the design to come after the initial idea.

“Non-design professionals often will say, okay, there’s a beginning of a process, a middle and an end. Whereas, from a design perspective and getting customers to come alongside, no, this is gonna be a helix forward. We’re gonna go up and down and all around in this process as we figure out what exactly we need to change.”

He explained the many small design changes made to improve the part, as adding geometric complexity in additive design makes sense in a way it doesn’t in traditional manufacturing. In the end, 3DEO updated the part so it was “below our maximum yield strength,” with uniformly distributed stress, fewer parts, and required much less labor to install, but was still tamper-resistant.

“That’s a case study example of us taking a customer set of requirements and them having the necessary openness,” he concluded. “A lot of times people say, ‘Print this,’ and that’s not a productive conversation. It’s like, well, this has been designed for sheet metal or something else.”

We’ve all heard some variation of this before, and that’s why DfAM is so important.

Want to explore how our high-purity copper can boost the performance and efficiency of your products? Connect with our team today.

Want to explore how our high-purity copper can boost the performance and efficiency of your products? Connect with our team today.