Aerospace metal Additive Manufacturing is transforming the industry and allowing greater flexibility and efficiency for specialized part production.

In this article, we will discuss the evolution, benefits, materials, design considerations, quality control, and future applications of additive manufacturing in aerospace.

From reducing weight and cost to enhancing performance and customization, metal Additive Manufacturing is opening new solution spaces in aerospace. Learn more about how 3D printing is used to create complex structures and components with unparalleled precision and efficiency.

Key Takeaways

- Metal Additive Manufacturing in aerospace allows for the creation of complex geometries, reducing the weight of aircraft components and improving fuel efficiency and performance.

- The use of high-performance alloys such as titanium, aluminum, and nickel-based alloys in metal Additive Manufacturing provides excellent strength-to-weight ratios and corrosion resistance, making AM ideal for aerospace applications.

- Design flexibility and customization are key benefits of metal Additive Manufacturing, allowing for the production of customized, intricate designs, as well as the consolidation of multiple parts into a single component.

- Quality control and certification processes are crucial in aerospace metal Additive Manufacturing to ensure part quality, reliability, and safety. Inspection techniques such as visual inspection, ultrasound, and dimensional measurements are used, and compliance with industry standards is required.

The Evolution of Additive Manufacturing in Aerospace

The evolution of aerospace manufacturing techniques has been a fascinating journey. In the early days, traditional manufacturing methods, such as casting and machining, were the norm. However, with the advent of Additive Manufacturing, a whole new world of possibilities opened up.

Additive Manufacturing, also known as 3D printing, has revolutionized the aerospace industry by allowing for the creation of complex geometries and reducing the weight of aircraft components. This has led to improved fuel efficiency and increased performance.

The impact of Additive Manufacturing on the aerospace industry cannot be overstated. It has allowed for faster production times, reduced costs, and greater design flexibility. As this technology continues to advance, we can expect even more high-impact innovations in the field of aerospace metal Additive Manufacturing.

Benefits of Metal Additive Manufacturing in Aerospace

Explore the advantages of incorporating this cutting-edge technology into your aerospace projects. Metal Additive Manufacturing offers numerous benefits that can revolutionize the way you design and produce aerospace components. Here are three reasons why you should consider implementing this technology:

- Cost Reduction: Metal Additive Manufacturing allows for the production of complex geometries in a single piece, eliminating the need for costly assembly processes. This not only saves time but also reduces material waste and labor costs.

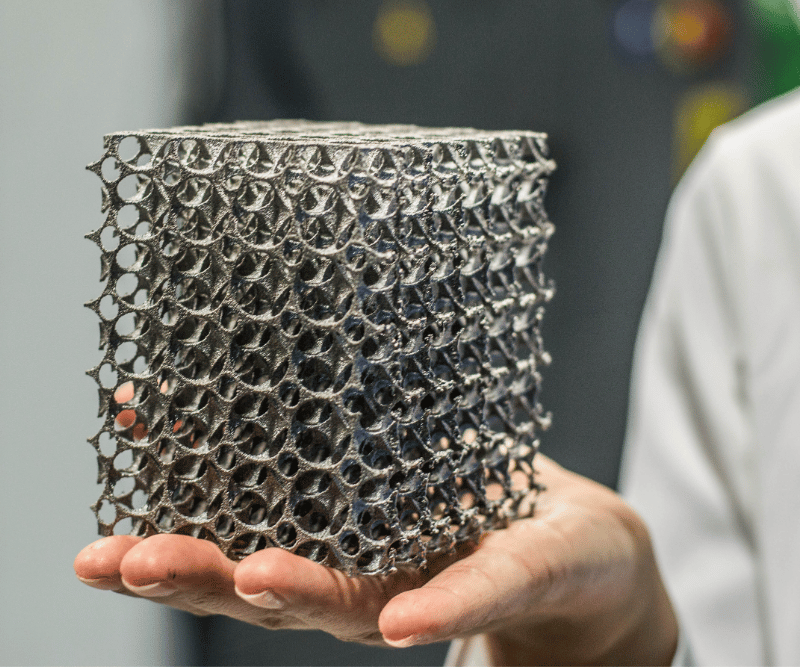

- Improved Performance: By utilizing Additive Manufacturing, aerospace components can be designed with optimized structures that enhance their performance. The ability to create intricate lattice structures and lightweight designs can result in improved fuel efficiency, increased payload capacity, and enhanced overall performance.

- Design Flexibility: With metal Additive Manufacturing, you have the freedom to create highly customized and intricate designs that were previously impossible to manufacture. This opens up new possibilities for innovation and allows for the creation of parts with improved functionalities.

Incorporating metal Additive Manufacturing into your aerospace projects can significantly cut costs and enhance performance, revolutionizing the industry.

Materials Used in Aerospace Metal Additive Manufacturing

By incorporating innovative materials, the possibilities for creating intricate and durable aerospace components through metal Additive Manufacturing are endless.

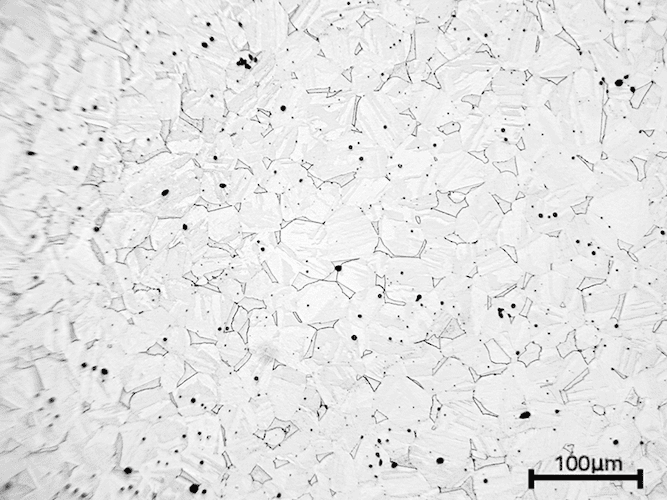

Alloy selection plays a crucial role in ensuring the desired mechanical properties of the printed parts. Aerospace metal Additive Manufacturing commonly uses high-performance alloys such as titanium, aluminum, and nickel-based alloys. These materials offer excellent strength-to-weight ratios and corrosion resistance, making them ideal for aerospace applications.

Moreover, surface finishing techniques in additive manufacturing are essential to enhance the mechanical and aesthetic properties of the printed parts. Techniques like polishing, sandblasting, and heat treatment can improve the surface roughness, remove imperfections, and optimize the part’s performance–imperative in aerospace applications.

The careful selection of materials and the use of advanced surface finishing techniques contribute to achieving the high-quality aerospace components demanded by the industry.

Design Considerations for Aerospace 3D Printing

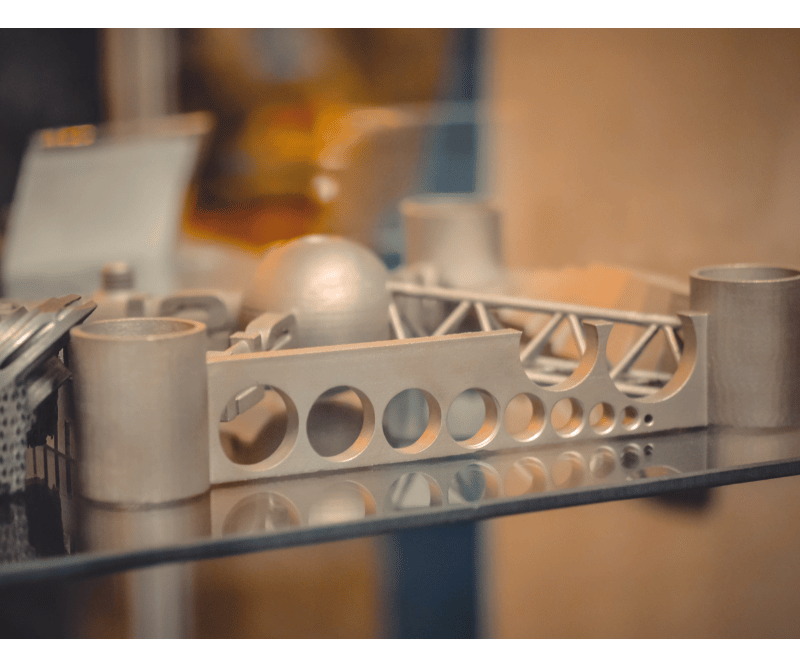

When considering 3D printing for aerospace applications, it is essential to carefully analyze several design aspects. Design complexity plays a crucial role in aerospace 3D printing. The technology allows for intricate designs that would be impossible or cost-prohibitive using traditional manufacturing methods.

Aerospace parts often call for complex geometries, internal channels, and lightweight structures that can improve overall performance–all achievable through Additive manufacturing techniques. 3D printing also offers the opportunity to consolidate multiple parts into a single component, reducing the number of assembly steps and potential failure points.

Another important consideration is cost-effectiveness. While initial setup costs for Additive Manufacturing can be high, the ability to produce complex shapes with minimal material waste can lead to significant cost savings in the long run.

Ultimately, understanding the design considerations for aerospace 3D printing is key to harnessing the full potential of this innovative technology.

Quality Control and Certification Processes

One crucial aspect to consider in 3D printing for aerospace applications is ensuring that quality control and certification processes are in place to guarantee the reliability and safety of the printed components.

Inspection techniques play a vital role in this aspect. They allow for the assessment of the printed parts’ quality and conformity to specifications. These techniques can include visual inspection, non-destructive testing methods like ultrasound or X-ray, and dimensional measurements.

Furthermore, regulatory compliance is essential to ensure that the printed components meet the required standards and regulations set by the aerospace industry. This involves adhering to specific guidelines and obtaining the necessary certifications to confirm the components’ reliability and safety.

Implementing robust quality control and certification processes is crucial for the successful integration of Additive Manufacturing in the aerospace industry.

Future Applications and Innovations in Aerospace Metal Additive Manufacturing

Innovations in aerospace 3D printing are paving the way for exciting future applications.

With ongoing research and development, new materials and processes are being explored to enhance the capabilities of 3D printing. Technological breakthroughs are enabling the production of complex geometries, reducing weight, and improving fuel efficiency in aircraft components.

Additive Manufacturing also offers the potential for on-demand production, reducing lead times and costs associated with traditional manufacturing methods. Furthermore, advancements in quality control and certification processes ensure the reliability and safety of 3D printed aerospace parts.

As the technology continues to evolve, the possibilities for innovation in aerospace metal Additive Manufacturing are limitless, opening up new horizons in aircraft design and production.

Frequently Asked Questions

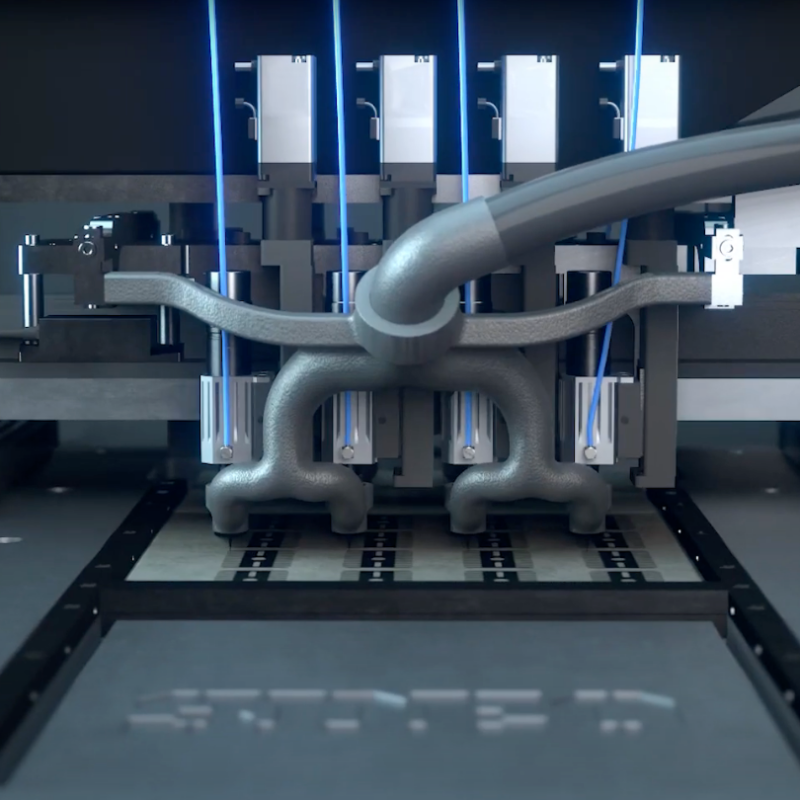

What are the different types of metal Additive Manufacturing processes used in aerospace?

There are various types of metal Additive Manufacturing processes used in aerospace, such as laser powder bed fusion and electron beam melting. These processes offer numerous benefits, including weight reduction, complex geometries, and advancements in technology for aerospace applications.

How does metal Additive Manufacturing compare to traditional manufacturing methods in terms of cost and time?

Metal Additive Manufacturing is more cost-effective than traditional methods due to reduced material waste and the ability to produce complex geometries. It is also time-efficient as it eliminates the need for tooling and allows for faster production.

Are there any limitations or challenges associated with using metal Additive Manufacturing in aerospace?

Using metal Additive Manufacturing in aerospace presents limitations and challenges. These include the need for specialized equipment, limited material choices, and the requirement for extensive testing and certification to ensure safety and performance.

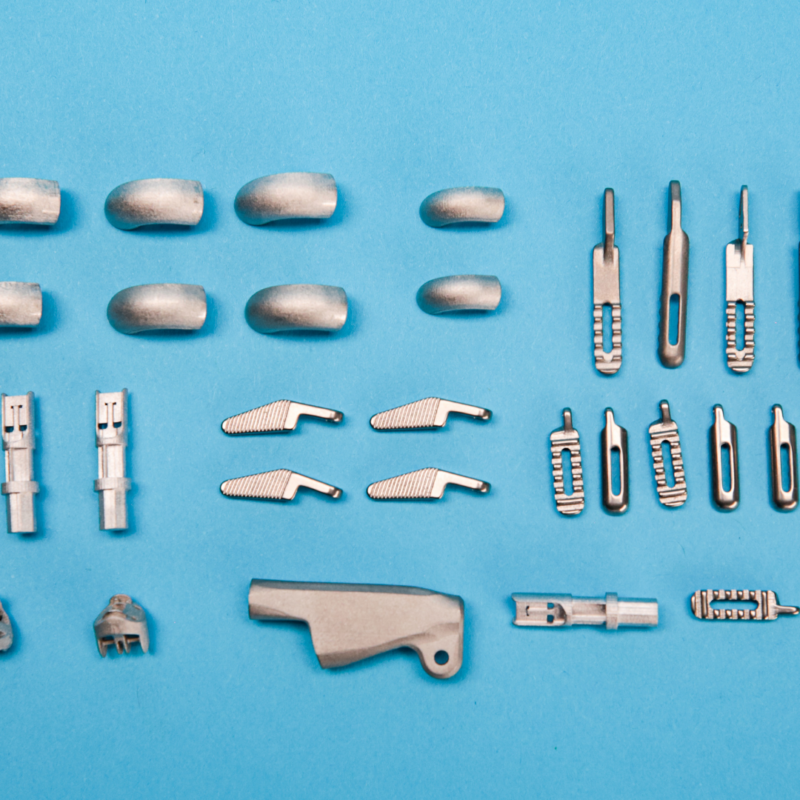

What are some real-world examples of aerospace components that have been successfully produced using metal Additive Manufacturing?

Real-world applications of metal Additive Manufacturing in aerospace include turbine blades, fuel nozzles, and engine components. The advantages are complex geometries, reduced weight, and improved performance, while disadvantages include high costs and limited material options. View our metal 3D printing for aerospace case study to learn more about a real-world example and the benefits of 3D printing for the industry.

How does the quality control and certification process differ for aerospace metal Additive Manufacturing compared to traditional manufacturing methods?

Quality control challenges in aerospace metal Additive Manufacturing include ensuring material integrity, dimensional accuracy, and surface finish. The certification process differs from traditional methods as it requires new standards and testing procedures to validate the reliability and performance of additively manufactured components.