Design for Additive Manufacturing (DfAM) is an approach that tailors the design process to harness the unique capabilities of additive manufacturing technologies.

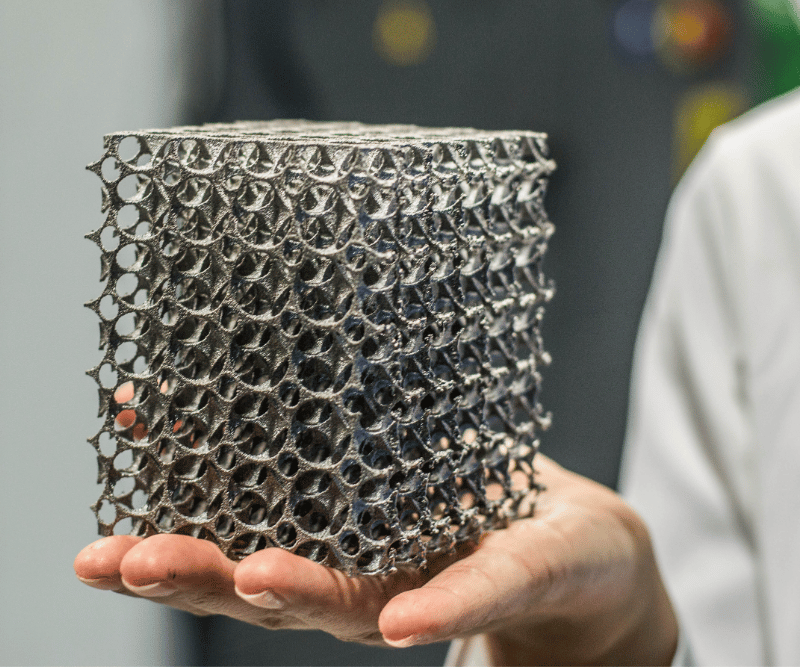

Unlike traditional manufacturing methods where designs often need to be adapted for production constraints, DfAM leverages the flexibility offered by additive processes to create complex, intricate, and optimized structures that were previously unachievable.

By capitalizing on additive’s layer-by-layer construction, DfAM aims to create parts that are not only functional but also efficient in terms of material usage, weight reduction, and improved performance–ultimately pushing the boundaries of design innovation.

In this article, we will explore the important factors that can impact the success of your metal 3D printing projects.

Key Takeaways

- Material selection is crucial in metal 3D printing, considering factors such as ease of transformation, surface quality, and cost.

- Proper part orientation optimization is essential to minimize distortion risks, control heat flow, and achieve desired surface finish.

- Designing effective support structures is important for stability and minimizing distortion, while design customization helps reduce build time and material consumption.- Design optimization for printability and functionality involves balancing complexity and cost, simplifying designs for efficient production, and considering functionality and ease of assembly/integration.

Material Selection for Metal 3D Printing

Different materials have varying surface finishes, corrosion resistances, weight and other considerations. It’s important to consider your desired outcome and choose a material that can achieve the qualities you envisioned for your project.

Cost considerations are vital in material selection for metal 3D printing. Some materials may be more expensive than others, and it’s important to weigh the cost against the desired characteristics and functionality of the final product.

By carefully considering both surface quality and cost, you can make informed decisions when selecting materials for metal 3D printing.

Understanding Part Orientation in Additive Manufacturing

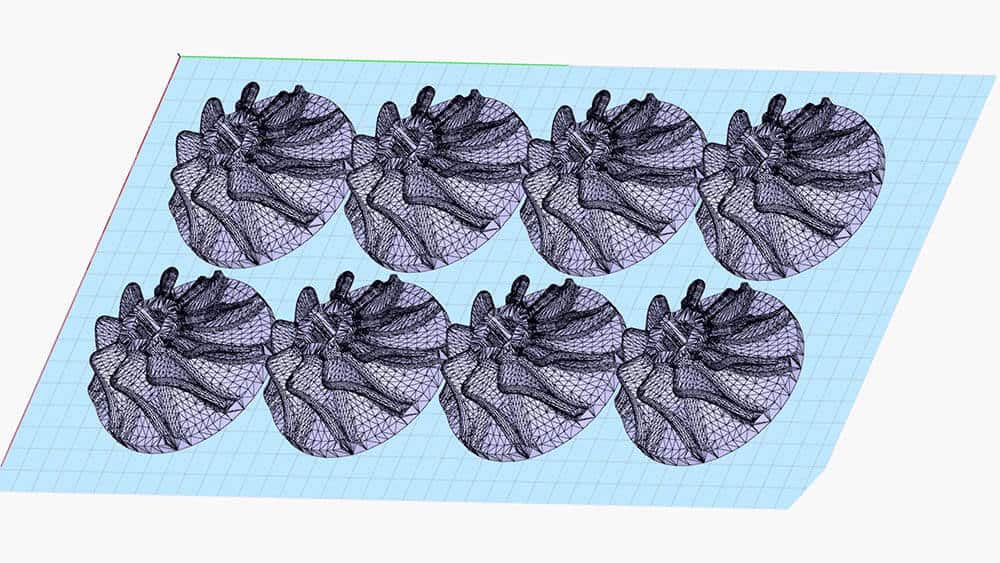

When designing for additive manufacturing, it is essential to consider the orientation of the part during the printing.

Proper part orientation helps in minimizing the distortion that can occur due to thermal stresses and uneven cooling. By strategically orienting the part, you can control the heat flow and reduce internal stresses, resulting in improved dimensional accuracy and part strength. Additionally, part orientation affects the surface finish, as well as the support structures required during printing.

By carefully considering part orientation, you can optimize the quality and functionality of your 3D-printed metal parts.

Designing Support Structures for Metal 3D Printing

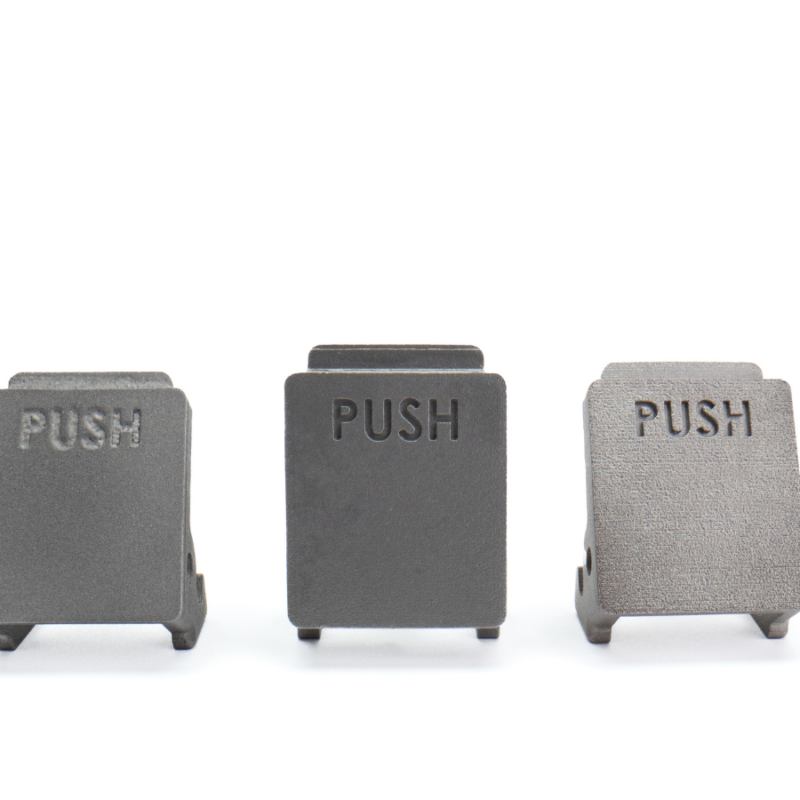

Designing support structures is important for optimizing the quality and functionality of 3D-printed metal parts. These structures provide stability during the printing process and minimize the risk of distortion and warping.

Customizable supports play a significant role in achieving successful prints in metal 3D printing. They are strategically placed to provide stability to overhanging or complex geometries, preventing them from collapsing during the printing process.

Tailoring the support structures to the specific design ensures that the part maintains its shape and dimensions accurately.

Efficient support structures also help reduce build time; By strategically placing supports only where necessary, material consumption is minimized, and the overall printing speed is enhanced. This leads to faster production and increased efficiency.

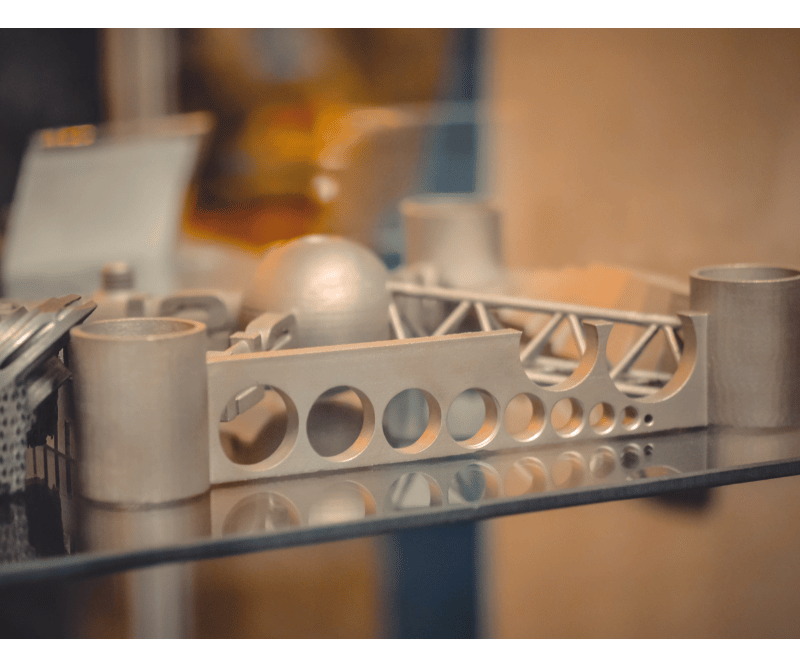

Optimizing Design for Printability and Functionality

Optimize your design by ensuring it is easily printable and functional, allowing for smooth production and a high-quality end result.

When designing for metal 3D printing, it is important to consider the complexity of your design. Keep in mind that intricate designs with very fine details may increase the cost of production. Therefore, it is crucial to strike a balance between design complexity and cost considerations. Simplifying your design where possible can help reduce production time and cost.

When considering the functionality of your design, it is imperative to ensure that it meets the intended purpose and can be easily assembled or integrated into the final product. By optimizing your design for printability and functionality, you can achieve efficient production and a successful end result.

Post-Processing and Finishing Techniques

Achieving a polished and professional look for your metal 3D printed object can be achieved through various post-processing and finishing techniques. These techniques not only enhance the aesthetic appeal of the object but also improve its functionality and durability.

Here are some common key post-processing and finishing techniques to consider:

– Surface treatment:

– Sanding: By using sandpaper or abrasive materials, the surface imperfections can be smoothed out, resulting in a refined finish.

– Polishing: This technique involves the use of polishing compounds or buffing wheels to create a smooth and shiny surface.

– Coating: Applying a protective coating, such as paint or lacquer, can give the object a finished look while also protecting it from corrosion.

Overcoming Challenges in Design for Additive Manufacturing

Overcoming challenges in the realm of 3D printing involves pushing the boundaries of creativity and problem-solving to achieve groundbreaking results.

When it comes to Design for Additive Manufacturing, there are specific challenges that need to be addressed. One of these challenges is designing for scalability.

As additive manufacturing continues to advance, companies are looking for ways to scale up production while maintaining quality and efficiency. This requires careful consideration of factors such as part orientation, support structures, and build time optimization.

Cost effectiveness in additive manufacturing is another challenge that designers face. Finding ways to reduce material waste, minimizing post-processing requirements, and optimizing machine utilization are all ways to make the process more cost-effective.

By addressing these challenges head-on, designers can unlock the full potential of metal 3D printing and revolutionize the manufacturing industry. By partnering with an expert DfAM firm, you can ensure that your project will fully leverage the benefits of 3D printing and maximize efficiency.

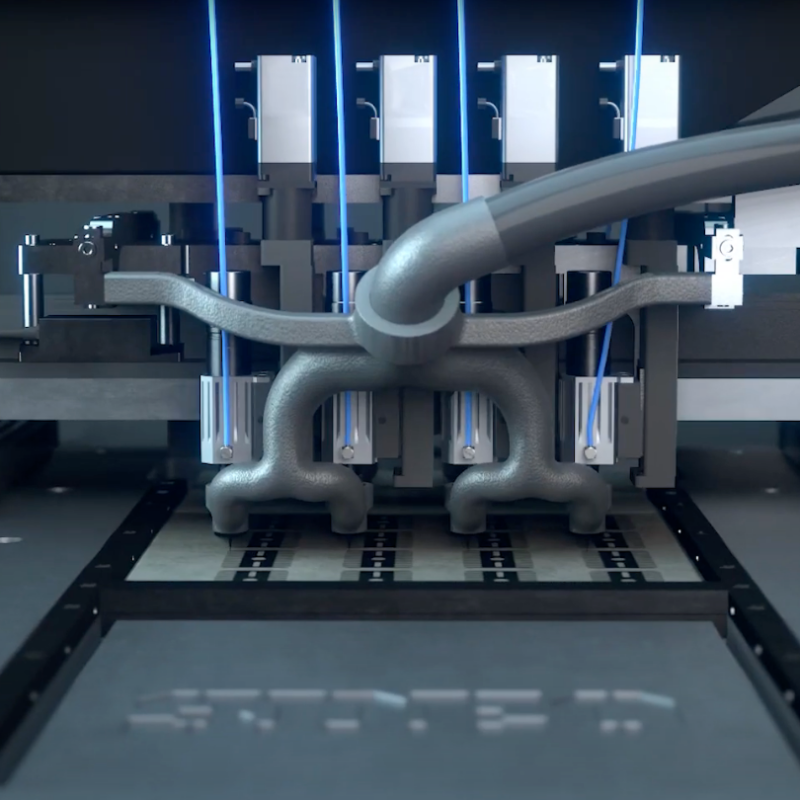

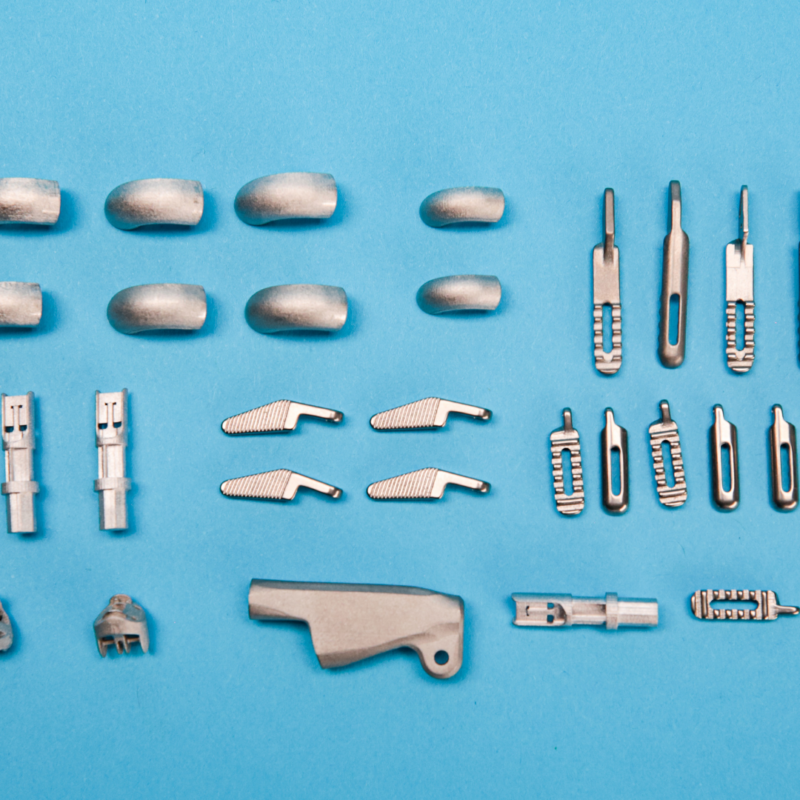

Partner with 3DEO to Optimize and Scale Intricate 3D Metal Parts

3DEO offers both expert DfAM and scalable 3D metal printing services. It’s time to scale up your metal part production game. Partner with 3DEO and leverage our advanced technologies to design, iterate, and manufacture intricate metal parts at a pace that matches your ambitions.

Join the discussion One Comment