In today’s unpredictable manufacturing environment, many companies are stuck between prototypes and full production. Tooling delays, tariff hikes, and overseas sourcing issues are stalling timelines and driving up costs.

Bridge production is how forward-thinking teams are breaking through the bottleneck. It fills the gap between prototyping and full-scale production—without requiring tooling or long-term commitments.

What Is Bridge Production?

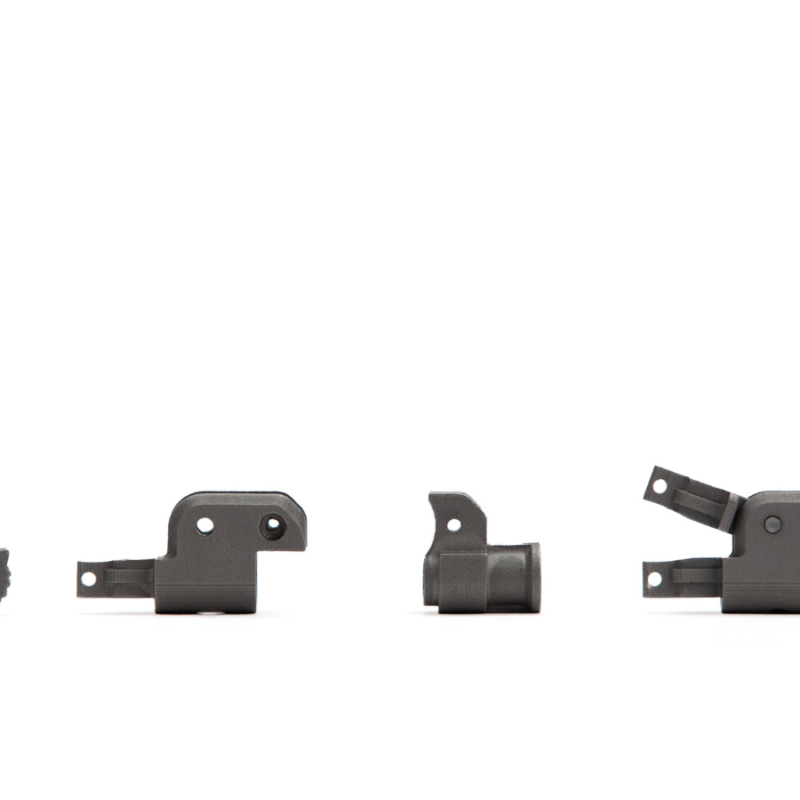

Bridge production is a short- to mid-term manufacturing solution that provides production-quality parts in moderate volumes (typically 500–10,000 units)—without investing in tooling.

It’s designed for companies that need to move quickly but aren’t ready (or able) to commit to long-term volume, tooling costs, or overseas production.

Why Is Bridge Production Gaining Momentum in 2025?

Global manufacturing challenges are pushing more teams toward flexible options:

- Tariffs and geopolitical shifts are increasing the risk and cost of global sourcing.

- Tooling lead times are stretching past 8–10 weeks in many industries.

- Product demand is harder to predict, especially for new or seasonal programs.

- Speed-to-market is now a competitive advantage.

Bridge production provides an agile alternative that keeps your supply chain moving.

How Bridge Production Works

- Submit your part or subassembly that’s affected by tooling delays, tariffs, or overseas bottlenecks.

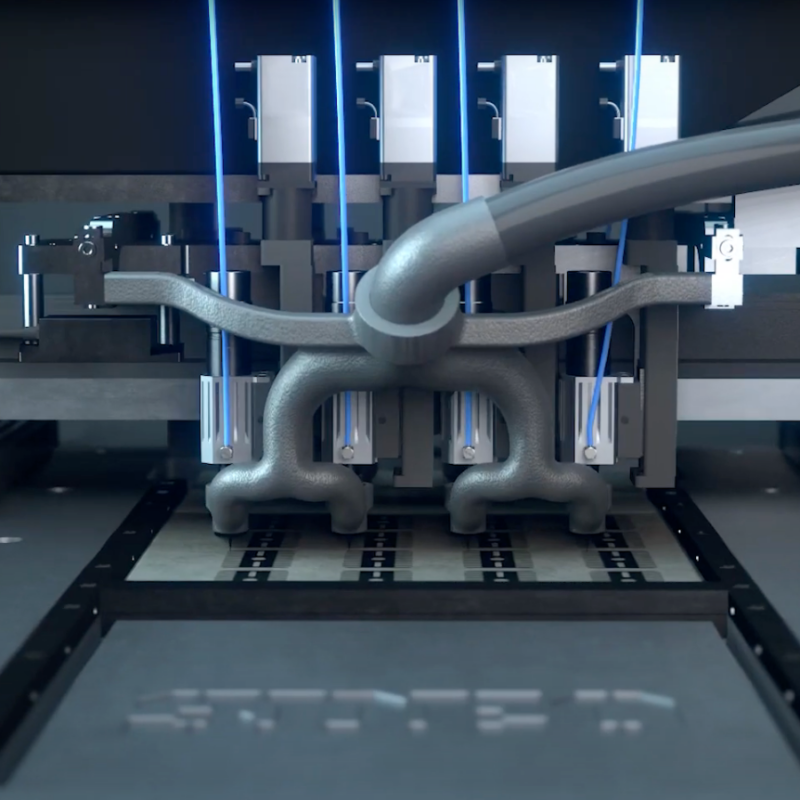

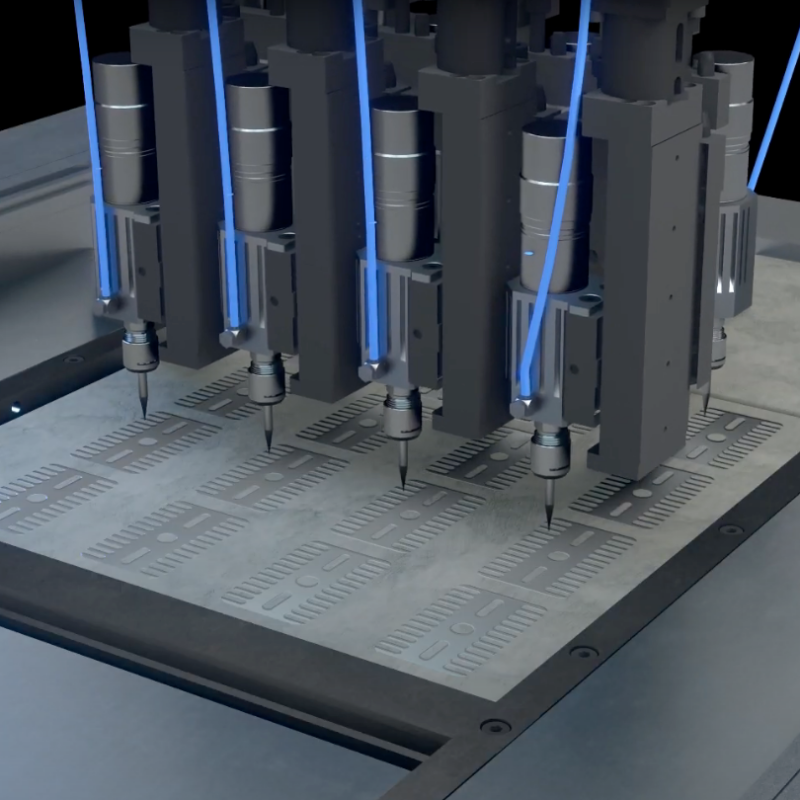

- A partner (like 3DEO) uses additive manufacturing—powered by proprietary processes like Intelligent Layering®—to produce production-grade parts without tooling.

- You get precision parts fast, in the volumes you need today (from 500 to 10,000 units).

- You scale into full production (like MIM) later, when it makes financial or operational sense.

When Bridge Production Makes Sense

Bridge production is ideal when:

- You’re launching a new product and want to validate demand before investing in tooling

- You’re stuck waiting on molds or overseas suppliers to deliver

- Tariffs are changing your landed cost calculations

- You need to fulfill early-stage volume (e.g., pilot programs, regulatory batches, launch inventory)

- You only need a small slice of production to hit milestones

Why Additive Manufacturing Is a Perfect Fit

Additive manufacturing (AM) is uniquely suited for bridge production because it’s:

- Tooling-Free – Get started faster without mold development

- Design-Friendly – Update part geometry without retooling

- Precision-Ready – Achieve consistent, repeatable quality

- Scalable – Move from bridge volumes to MIM or higher-volume production with confidence

3DEO Insight

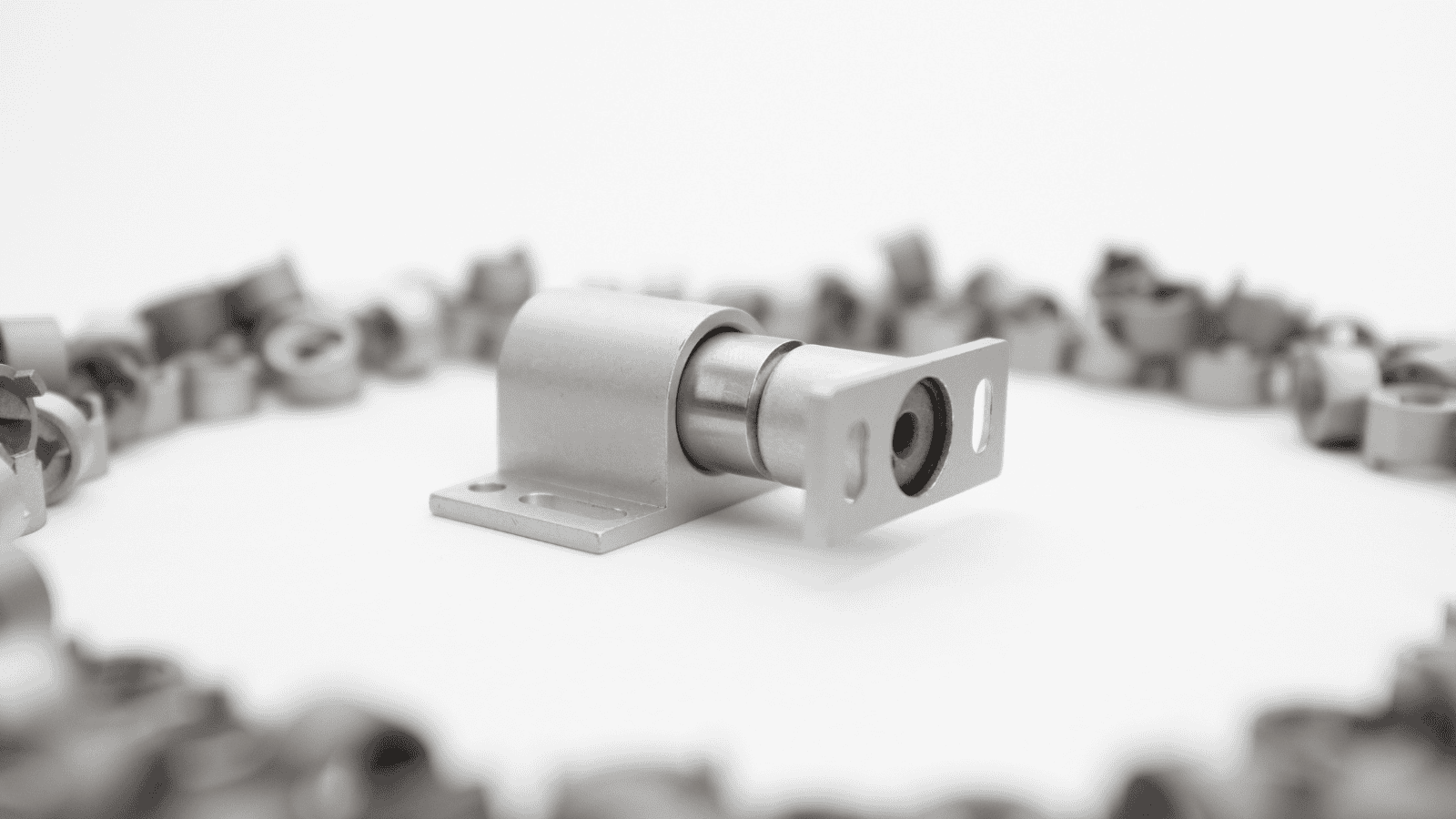

At 3DEO, we specialize in tooling-free, production-grade metal parts using our proprietary Intelligent Layering® process—designed for fast, repeatable, high-precision production at scale.

👉 Learn how Intelligent Layering® works and why it’s a breakthrough for complex metal components.

Frequently Asked Questions

What is bridge production in manufacturing?

Bridge production fills the gap between prototyping and full production, offering short-to-mid-run production without tooling investment.

Why is bridge production important in 2025?

It offers flexibility when tooling is delayed or overseas suppliers are unavailable—especially amid rising tariffs and lead time risk.

Can additive manufacturing support bridge production?

Yes—AM is ideal for tooling-free, precision-grade parts in volumes up to 10,000 units.

Conclusion: Why It Matters Now

If your production is stuck—waiting on tooling, navigating tariffs, or facing uncertainty—bridge production may be your best move.

It gives you the ability to move forward with confidence, stay on timeline, and reduce risk.

Ready to get started?

Upload your part and we’ll help unlock your production.

Join the discussion One Comment