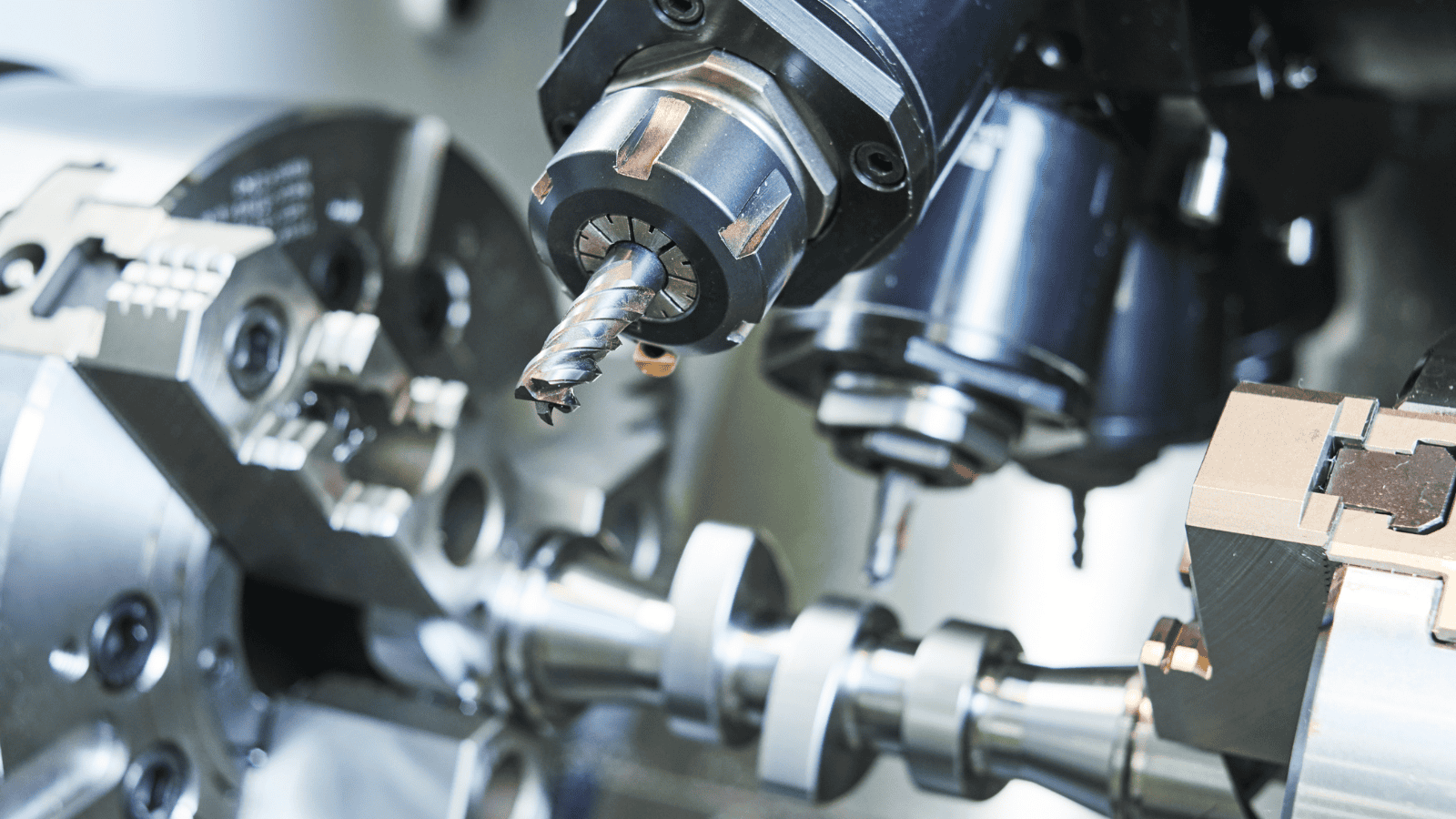

CNC machining and casting are powerful processes—but they weren’t designed for every part.

In some cases, trying to force a complex or high-performance part into a traditional method can lead to compromises in cost, lead time, and functionality.

Here are five signs your part might be better served by additive manufacturing (AM) instead.

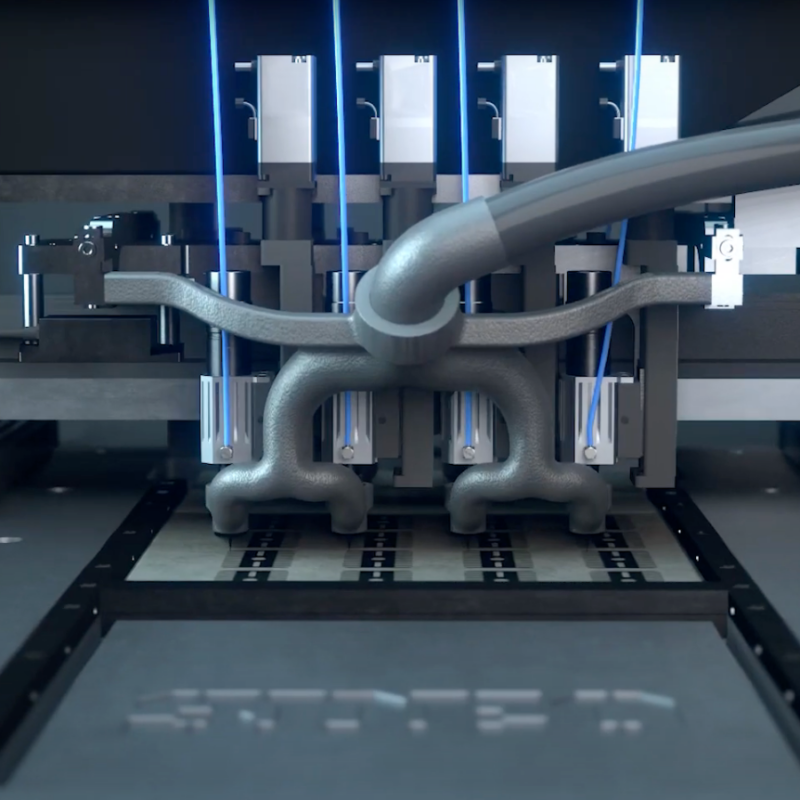

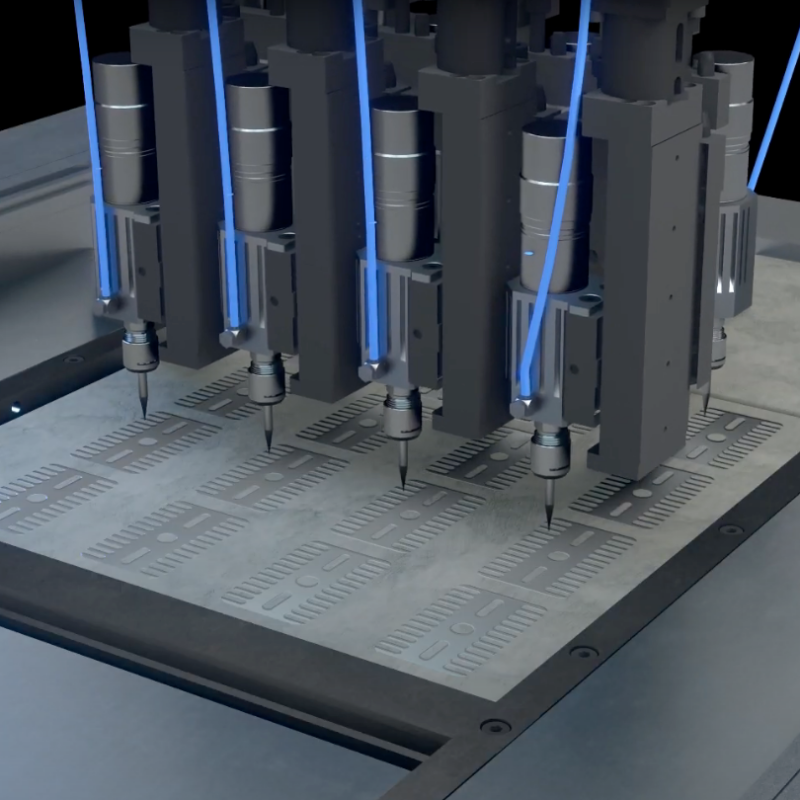

1. Your Part Has Internal Channels or Hidden Geometry

CNC machining requires line-of-sight.

Casting requires draft angles and moldability.

If your part needs internal cooling channels, fluid pathways, or features that are enclosed by design, you’re likely in for a major design rework—or multiple assemblies.

✅ AM makes these features possible in one solid build.

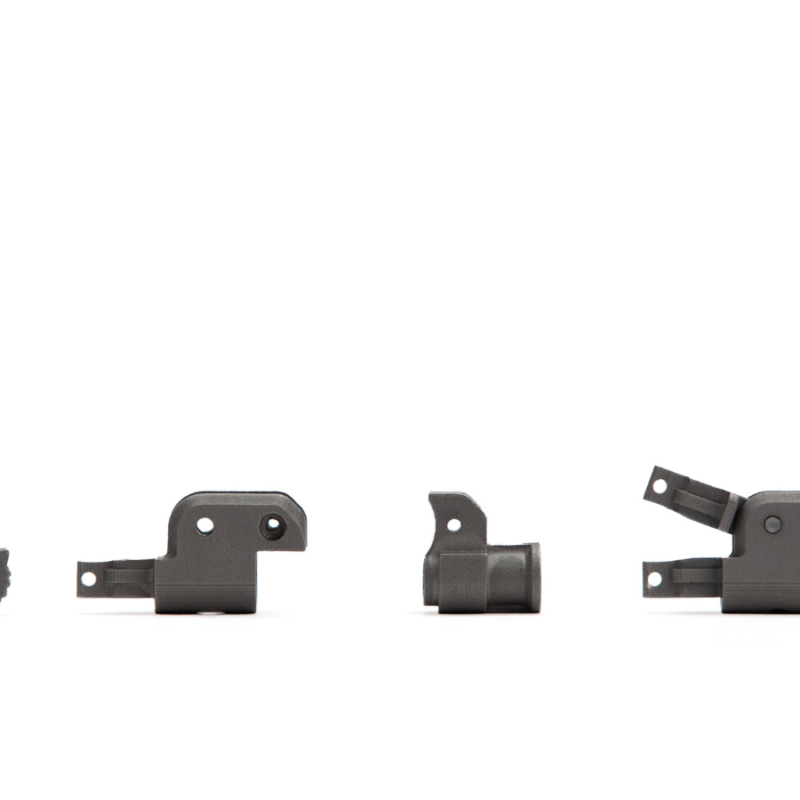

2. You’re Using Multiple Parts to Get Around Machining Constraints

If your “one part” is actually three bolted or welded together just to get around tool access or mold limitations, you’re not designing for performance—you’re designing for process.

✅ Additive lets you consolidate those components into a single, optimized part that reduces weight, complexity, and failure points.

3. Thin Walls or Organic Surfaces Are a Problem

Thin features, organic curves, and evolving contours are tricky (or impossible) to machine. Casting them often leads to warping or defects.

✅ Additive handles these features with ease, giving you the design freedom to shape parts exactly as needed—without working around tooling or toolpath limits.

4. Your Timelines Can’t Wait for Tooling

Casting and certain CNC jobs require weeks of lead time just for setup or mold creation. If you’re racing to launch, those delays add risk and cost.

✅ Additive can often deliver production-grade metal parts in as little as 2–4 weeks. No tooling. No waiting.

5. You’re Compromising Performance to Fit the Process

If your design was changed just to make it machinable or moldable—less geometry, fewer features, thicker walls—you might be giving up performance.

✅ With AM, you don’t have to strip your design down to make it fit.

Instead, we help you optimize it for function, then manufacture it at the quality level you need.

The Bottom Line

Traditional manufacturing isn’t going away—but it’s not always the best fit for performance-driven parts.

If your design is being limited by machining or casting, it might be time to look at additive. Not just to print for the sake of printing—but to print where it makes the part better.

Start your design review — we’ll help you figure out what fits where.