There’s a lingering myth in metal additive manufacturing:

“It’s good for prototypes, but the surface finish isn’t production-grade.”

That might’ve been true ten years ago. Today? It’s a different story—especially at 3DEO.

Here’s why surface finish still matters in additive, where traditional AM can fall short, and how 3DEO raises the bar with high-quality, production-ready parts.

Let’s Be Real: Finish Isn’t Just Cosmetic

Sure, finish affects how a part looks. But more importantly, it affects:

- Fit – Especially for assemblies and mating surfaces

- Friction – In moving parts, fluid flow, and wear points

- Function – For seals, threads, and mechanical contact

- Downstream operations – Like coatings, painting, or joining

Poor surface quality isn’t just aesthetic—it creates real engineering problems.

Why Most Additive Parts Feel “Rough”

Traditional powder-bed fusion and binder jetting can leave:

- Stepped layers on sloped surfaces

- Porous or grainy textures

- Rough edges that need secondary machining or polishing

These issues are why many teams assume additive = unfinished.

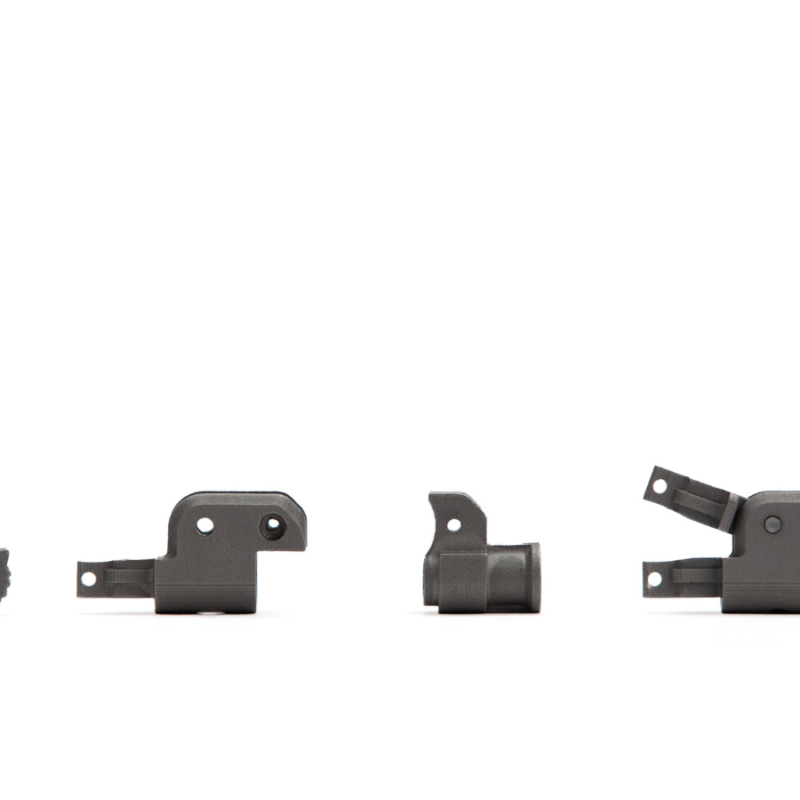

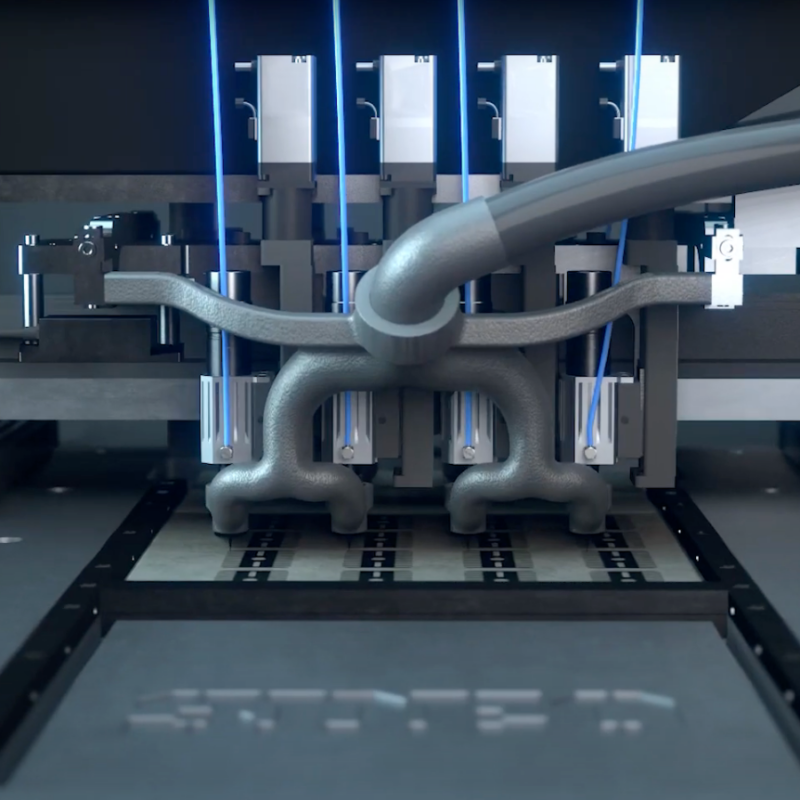

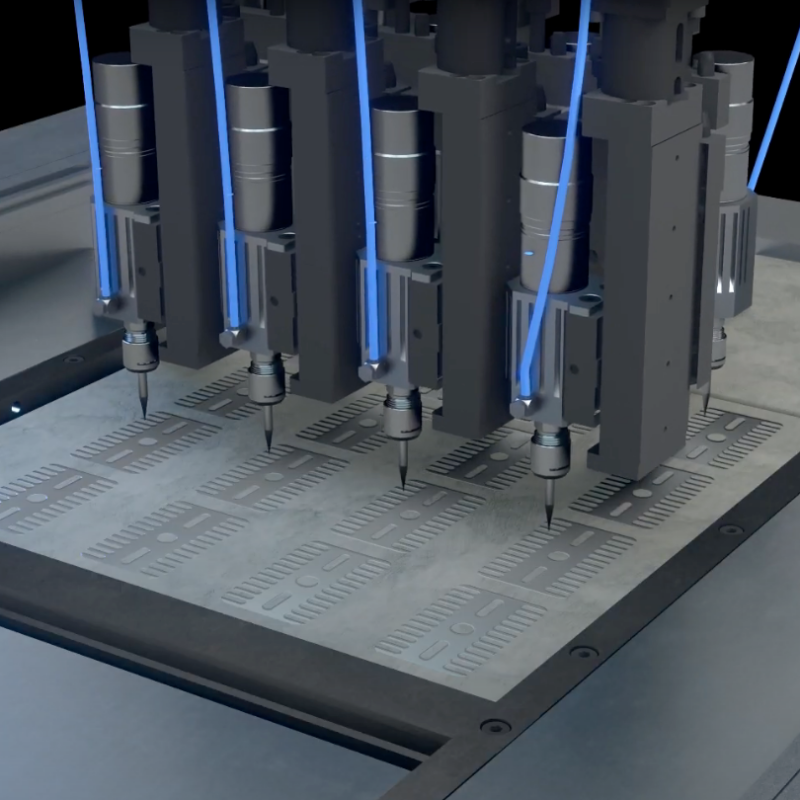

How 3DEO Is Different

We built our process from the ground up to deliver high-resolution, high-consistency metal parts—no rough prototypes here.

With 3DEO’s Intelligent Layering® platform, you get:

- Smooth surface finishes right out of the process

- No visible layer lines or rough grain

- Production-grade dimensional repeatability

- Tighter tolerances and fine features—without extra finishing work

It’s what makes our parts suitable for bridge production and full-scale manufacturing—not just validation.

Real Talk from Engineers:

“We sent a part to 3DEO expecting to just test geometry. What we got looked like something you’d pull from a finished inventory bin—not a prototype.”

Why It Matters in DfAM Projects

Design freedom is only valuable if your part performs as expected. Finish impacts:

- Aerodynamics

- Cooling flow paths

- Wear life

- Assembly success

- Certification + consistency at production scale

If your part needs to look good, seal well, or slide cleanly—surface finish matters.

The Bottom Line

Not all AM is created equal.

If you’ve avoided additive because of rough surfaces or prototype-only quality, it’s time to re-evaluate what’s possible.

At 3DEO, we focus on print quality, precision, and finish—so you get parts that perform right off the printer.

Want to see it for yourself?

Start a design review