If you missed this webinar, you can watch it here: The True Economics of Metal AM: What You Need To Know To Succeed

Here are the highlights from this webinar:

Between enabling profound new designs and upending the traditional supply chain, the unlimited potential with metal 3D printing will transform the manufacturing landscape. Indeed, the transformation has already begun. But, getting metal AM into production is taking a lot longer than many media pundits predicted. It’s even progressing much slower than many “in-the-know” industry insiders expected.

Why is mass adoption so slow with metal 3D printing, especially in production? It really boils down to one word: economics. If the economics work, the application moves forward into production. If not, it’s dead on arrival. The numbers need to work because when it comes to production competitive manufacturing, technologies come into play. Customers start to say things like, “Well, if I make a couple modifications to the design I can use CNC machining or metal injection molding and save a huge amount on the production cost.”

If you’re interested in getting into production with metal 3D printing, there is a lot you should be aware of before you make the leap.

When it comes to developing commercial applications using 3D printing, economics is the top reason for failure or success. Consequently, it becomes incredibly important for us to understand the true economics of metal AM. Doing so will allow us to gain a better understanding of where metal 3D printing fits in the manufacturing landscape and how we can compete and win against traditional metal fabrication techniques.

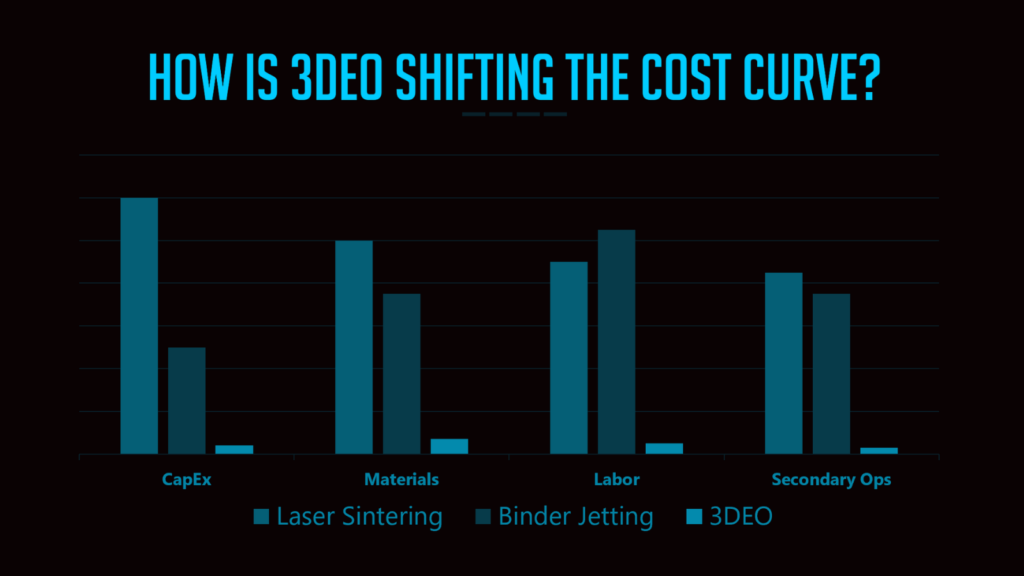

What drives cost in metal AM? There are four key cost drivers:

- Machine time (amortization) – each hour on a printer is expensive, particularly for multi-million dollar machines.

- Materials cost – materials cost in high-throughput processes is typically 50-70% of the final part cost; metal AM materials are usually much more expensive than traditional materials.

- Labor cost – the time employees need to spend on the part to get it ready for production after printing.

- Secondary operations – any modifications to the part (e.g., machining or heat treating) that need to happen after the part has been printed.

If you’re interested in learning more about the true economics of metal additive manufacturing, tune in to the upcoming webinar by Matt Sand, President of 3DEO. Matt will dive much deeper into the cost drivers and how to move 3D printed applications into production.

At 3DEO, a metal additive manufacturing service bureau, Matt has helped customers from many industries choose metal 3D printing as its production technology. 3DEO is gaining significant commercial traction not because of its sexy 3D printing technology, but because the economics work for its chosen applications.

Using real-world case studies from a variety of industries, the webinar will cover everything it takes to transition your product into production with metal additive manufacturing, including:

- What are the fundamental cost drivers for metal AM?

- Why do we mostly hear about successful applications of metal AM in the aerospace industry? Why aren’t more industries starting to leverage metal AM?

- What are common pitfalls and hidden costs associated with metal AM?

- How should I choose a great candidate for metal AM?

- How do I calculate infrastructure requirements based on throughput?

- What is the true ROI of end-to-end production in AM?

- What’s the most successful way to get started with AM?

To learn everything you should be aware of before you get into production with metal 3D printing, watch the webinar now.