Overview of Material Jetting in Metal 3D Printing

Material Jetting is relatively new and similar to binder jetting, with one key difference — instead of a binder being jetted through the printhead, a metallic material is jetted. This material is jetted onto the build tray directly using either a continuous jetting or Drop on Demand (DOD) process. The jetted metal is deposited on the build tray in the cross section of the part for that layer. This process continues as it builds up layer after layer. The resulting part still needs to be sintered in a furnace to achieve final part density. Previously, material jetting was limited to plastics and polymers, but recent advances have seen new companies attempting to commercialize the process for metals. XJet currently shows the most promise for material jetting with its patented NanoParticle Jetting technology and recently shipped its first commercial machine to a customer.

3DEO Series: An Introduction to Metal 3D Printing

This post is part 7 of a guide by 3DEO meant to introduce engineers and designers to metal additive manufacturing. Subscribe to our email list to stay current on all of our articles.

The other articles in the series are:

1) What is Additive Manufacturing? An Intro & Benefits

2) Overview of the Metal 3D Printing Processes

3) Intro to Powder Bed Fusion (DMLS, SLS, SLM, LMF, DMP, EBM)

4) Metal Additive Manufacturing (AM) Processes – Binder Jetting

5) Metal 3D Printing Processes – Metal Extrusion FFF/FDMle

6) Metal 3D Printing Processes – Directed Energy Deposition (DED)

Advantages of Material Jetting

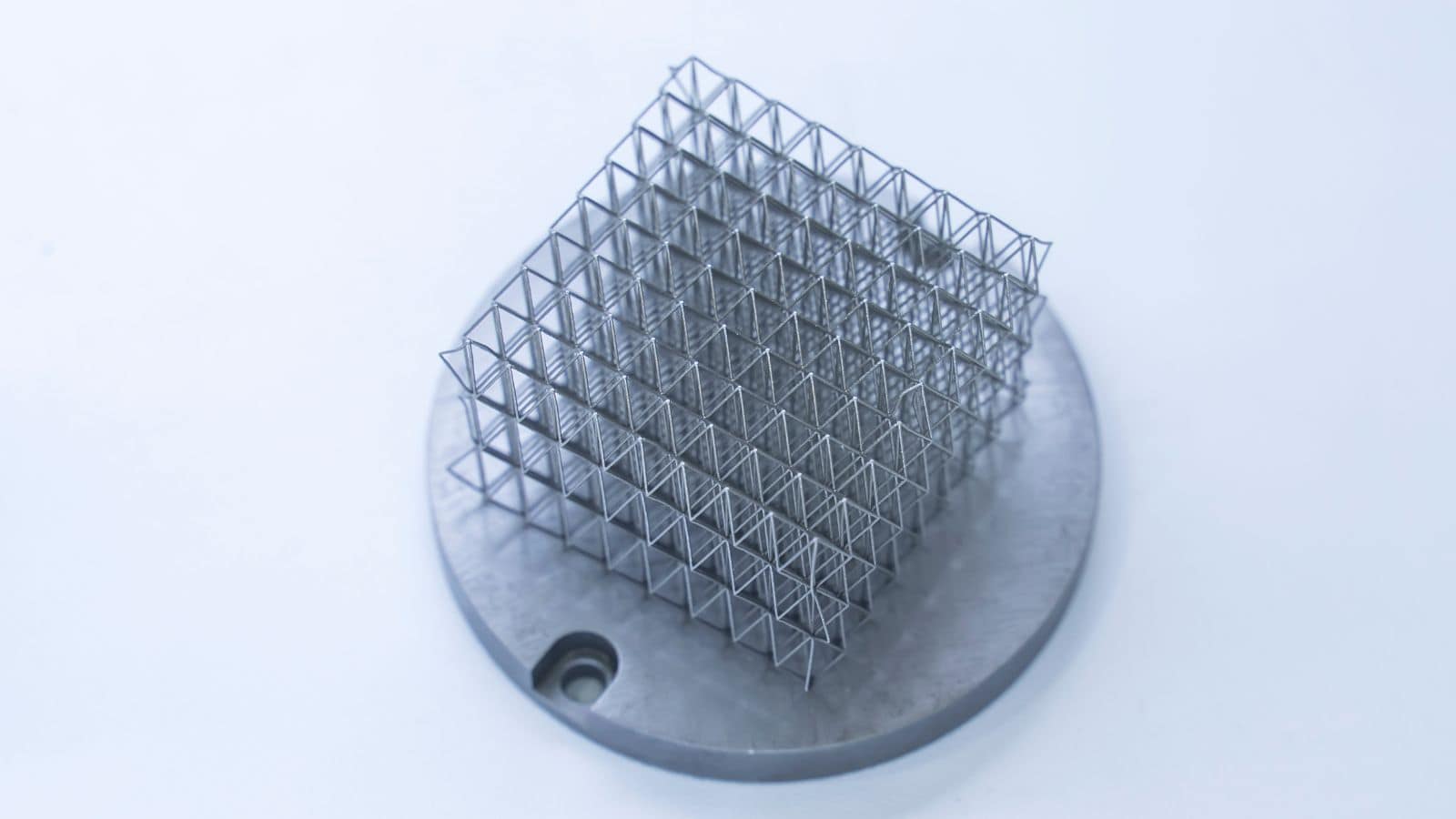

The metal particles being jetted are nanoscale and the resulting layer thickness is extremely thin as compared to other additive technologies. These ultra-thin layers produce very high-resolution parts where the layers are nearly invisible to the human eye. Much like metal extrusion-based additive manufacturing, material jetting does not use loose metal powder. This theoretically expands the number of materials that can be used safely since many common metals such as aluminum and titanium are extremely combustible in powder form and require significant precautions when being handled.

- High resolution due to nanoscale jetting

- Safer and easier to handle with no loose powder

- Very nice surface finish

Disadvantages of Material Jetting

The downside to using very thin layers is that many more are needed for a given part size as compared to other additive technologies with thicker layers. Adding more layers takes more time, and most of the parts shown as examples of metal material jetting appear to be rather small. Since the machines are just now coming to market, the machines are still expensive with limited throughput.

- Very slow process

- Most applications limited to small parts

- Parts are very expensive

Applications of Material Jetting

The first applications of this technology appear to be in creation of small intricate parts requiring the high-level of resolution offered by the thin layering process. Small flow control valves and devices are good candidates for this technology, along with other metal parts requiring complex internal geometries and tight tolerances. Being a nascent technology, metal material jetting needs more exposure and excitement surrounding it to drive further innovation.

Work with 3DEO

3DEO makes high quality metal components with our proprietary metal 3D printers. We specialize in manufacturing low/medium volumes on demand, which means there’s no need to worry about long lead times, minimum order quantities, or high tooling/setup costs.

{{cta(‘8e2d4675-7c44-4d4b-99af-c8ef1aa04dce’)}}