Metal Injection Molding (MIM) is a powerful manufacturing process — high volume, low cost per part, and great material properties. But MIM comes with one unavoidable reality: tooling.

And in today’s manufacturing environment, tooling can be expensive, time-consuming, and limiting.

So what do you do when MIM isn’t quite ready — but you still need production-quality metal parts?

That’s where bridge production steps in.

The Case for MIM — Eventually

MIM is often the right choice when:

- Your volume is high (typically 10,000+ parts/year)

- Your design is locked

- You’re ready to invest in tooling

- Your timelines can handle 8–12+ week lead times

But what if just one of those things isn’t true?

The Problem with Committing Too Early

Tooling costs for MIM can range from $10K to $100K+ depending on part complexity. And once you’ve tooled up, your design is locked in. If you’re still iterating — or unsure of long-term demand — that investment can backfire.

In 2025, we’re seeing more companies held up by:

- Unpredictable demand forecasts

- Long tooling timelines

- Tariff-driven supplier shifts

- Early-stage program needs (e.g., pilot runs or validation batches)

Bridge Production: Your Smart First Step

Bridge production allows you to:

- Get 500–10,000 high-quality, production-grade metal parts fast

- Skip tooling entirely

- Start with a flexible design and update as needed

- Prove demand, pass testing, or hit milestones before committing to MIM

It’s the best of both worlds: fast enough to hit your deadlines, and flexible enough to adjust before scaling.

From Bridge to MIM — With Support

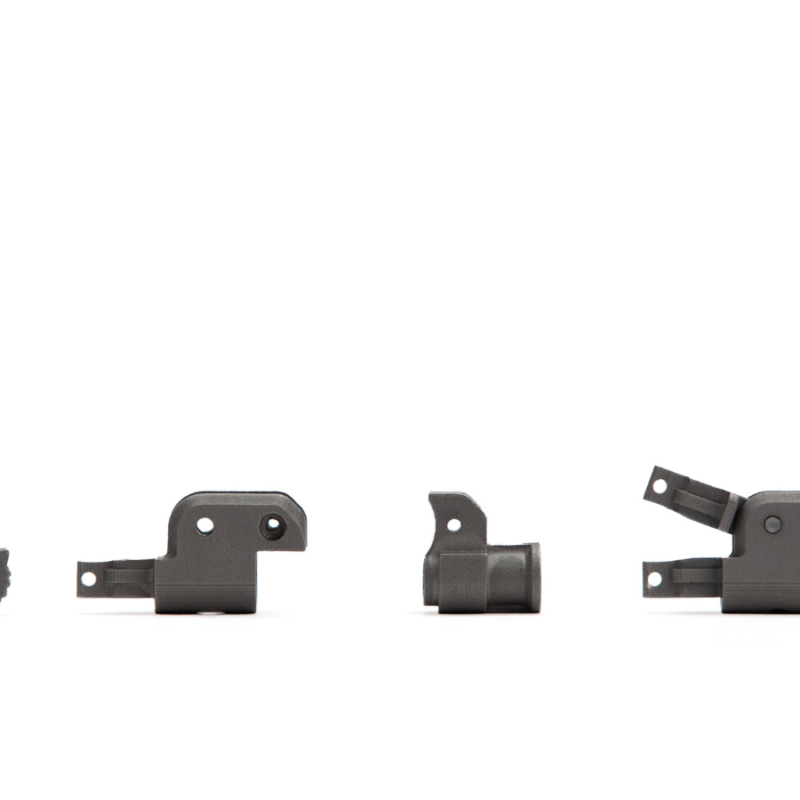

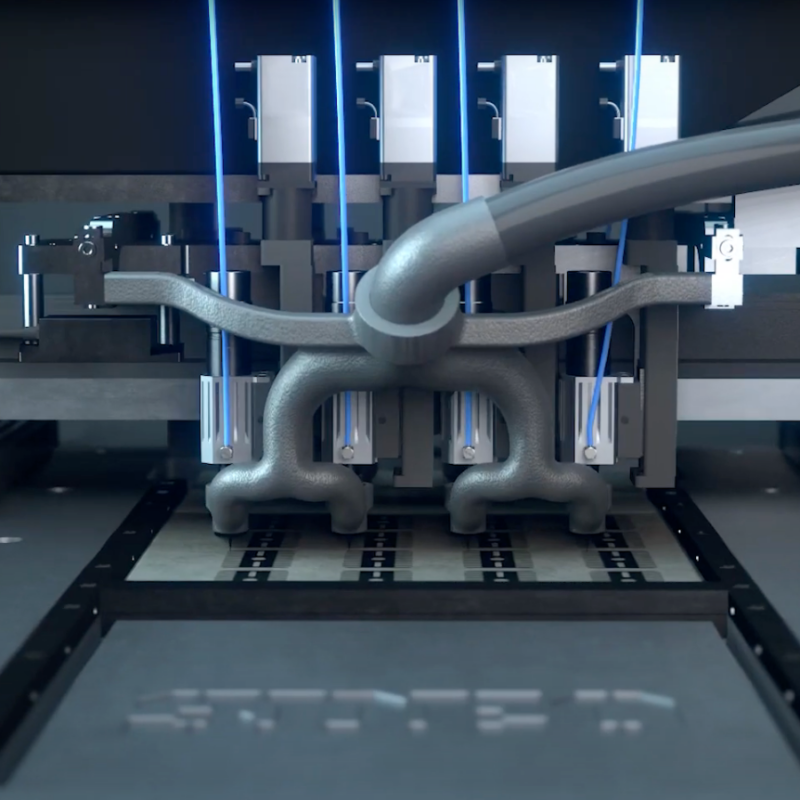

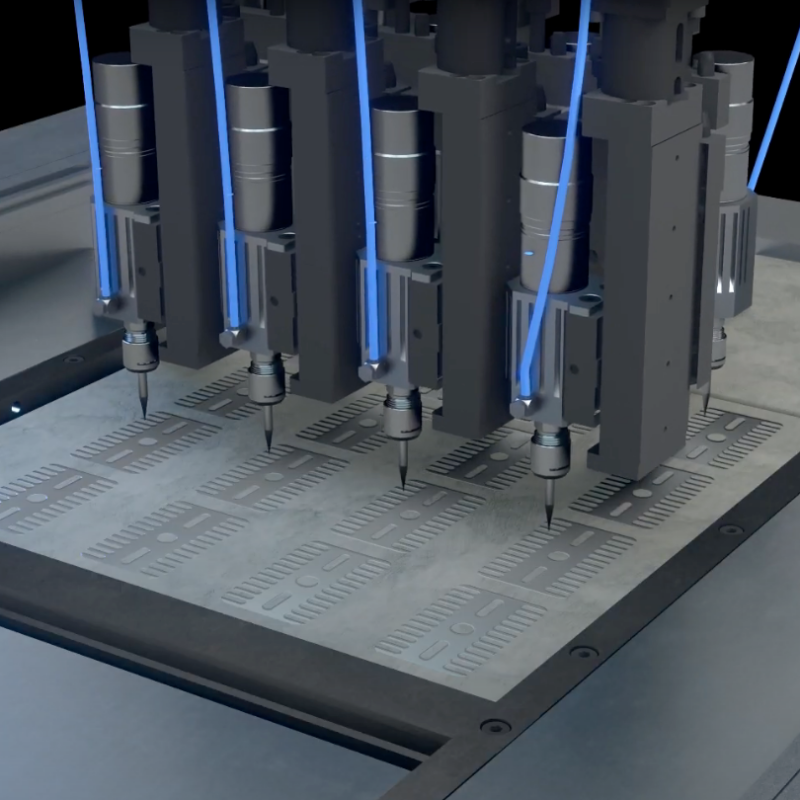

At 3DEO, we help companies bridge to MIM the right way. Our parts are made using Intelligent Layering® — a proprietary additive process that delivers high-quality, production-grade parts without tooling. When the time comes to move to MIM, we support the transition with DfAM guidance and supplier handoff.

The Bottom Line

You don’t have to commit to tooling just to get production moving.

Start with a bridge. Scale into MIM when it makes sense.

It’s faster, more flexible, and better aligned with how modern teams operate.

Ready to get started?

Upload your part and we’ll help unlock your production.