Assembly complexity is one of the most overlooked sources of cost, delay, and risk in manufacturing.

Every additional component adds more sourcing, more tolerance stacking, more failure modes, and more labor. That’s why part consolidation—done right—has a huge impact on both performance and profitability.

Additive manufacturing (AM) opens the door to consolidation opportunities that traditional manufacturing simply can’t support.

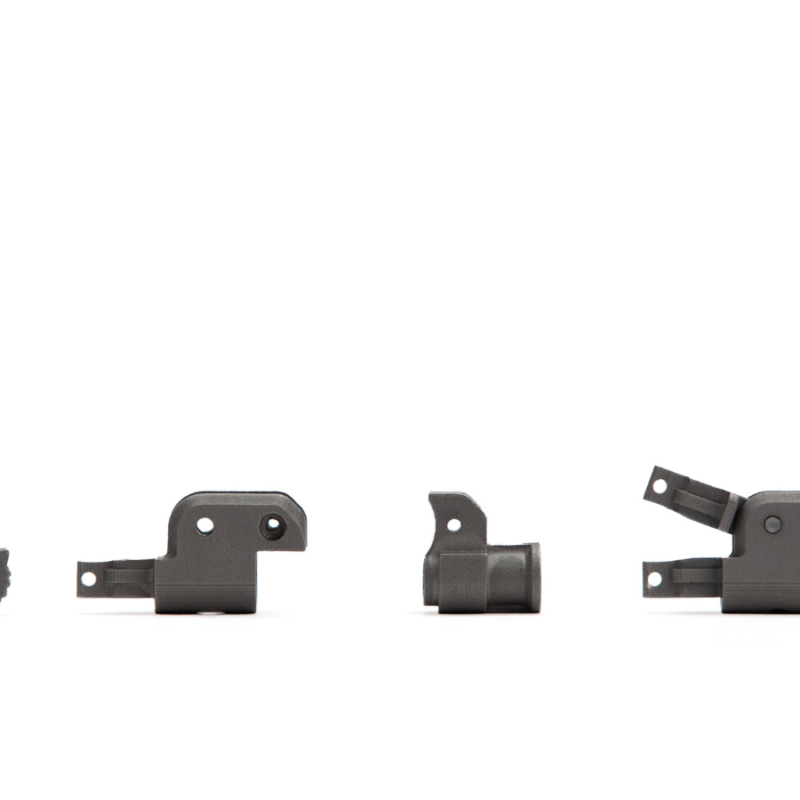

What Is Assembly Consolidation?

In short: fewer parts, smarter systems.

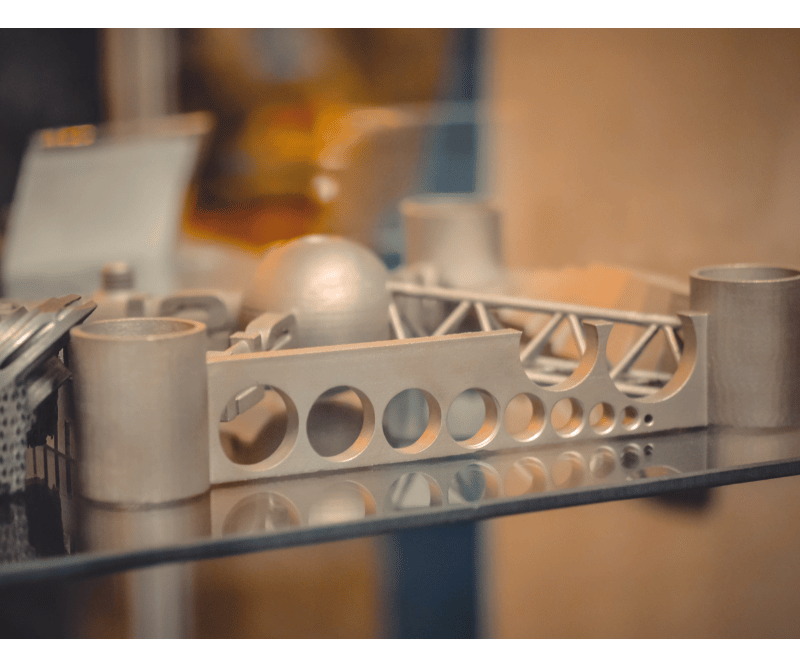

It means reducing the number of components in an assembly by combining functions and geometry into one part—ideally, without sacrificing performance or serviceability.

The payoff:

- Reduced sourcing and BOM complexity

- Lower part count and fewer fasteners

- Shorter assembly time

- Better reliability

Why Traditional Methods Limit Consolidation

With CNC or casting, geometry drives complexity—and cost. Many designs are split into multiple components because:

- Tool access is limited

- Internal features are difficult or impossible to machine

- Tolerances stack up across connections

- Multi-axis operations increase cost

So engineers are forced to break parts apart just to make them manufacturable.

What Additive Unlocks

AM removes those constraints and allows you to:

- Combine multiple parts into one printed component

- Include internal channels, support geometry, and alignment features in the design

- Eliminate fasteners, brackets, and redundant hardware

- Design for function—not process limitations

And because additive requires no tooling, these improvements can be made on shorter timelines and lower volumes than ever before.

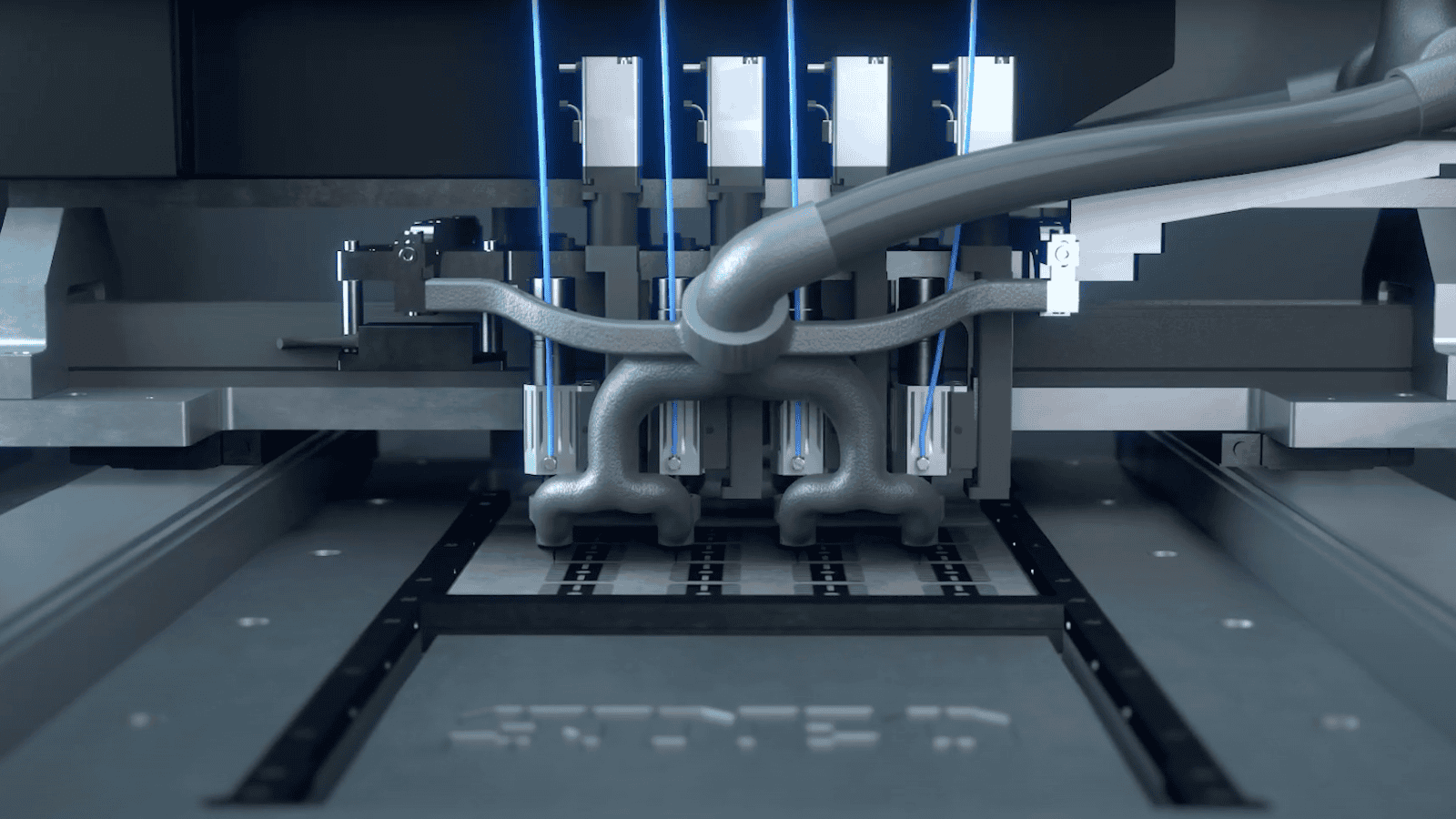

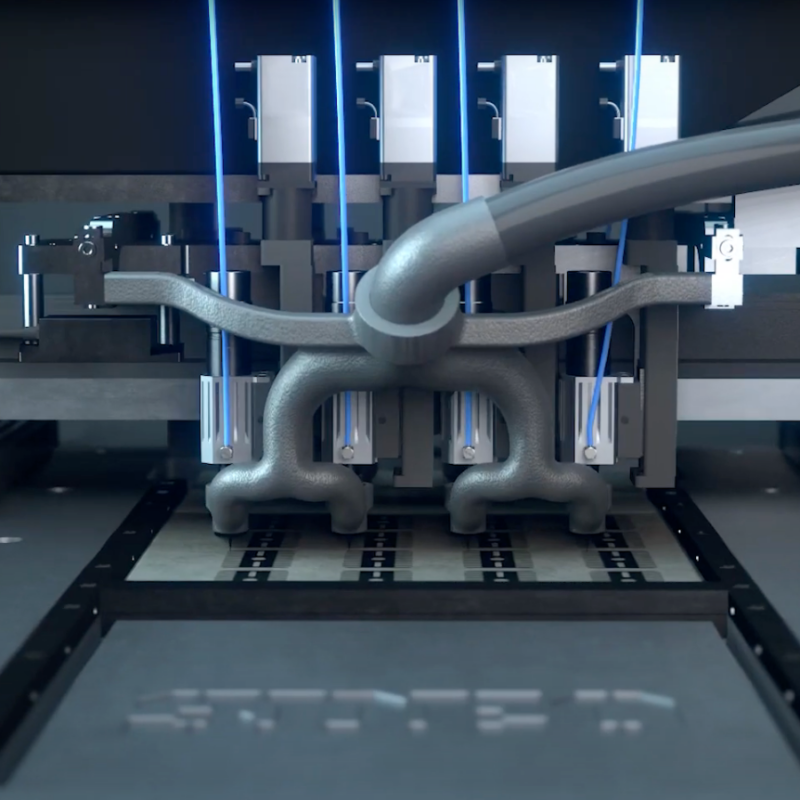

Why It Works at 3DEO

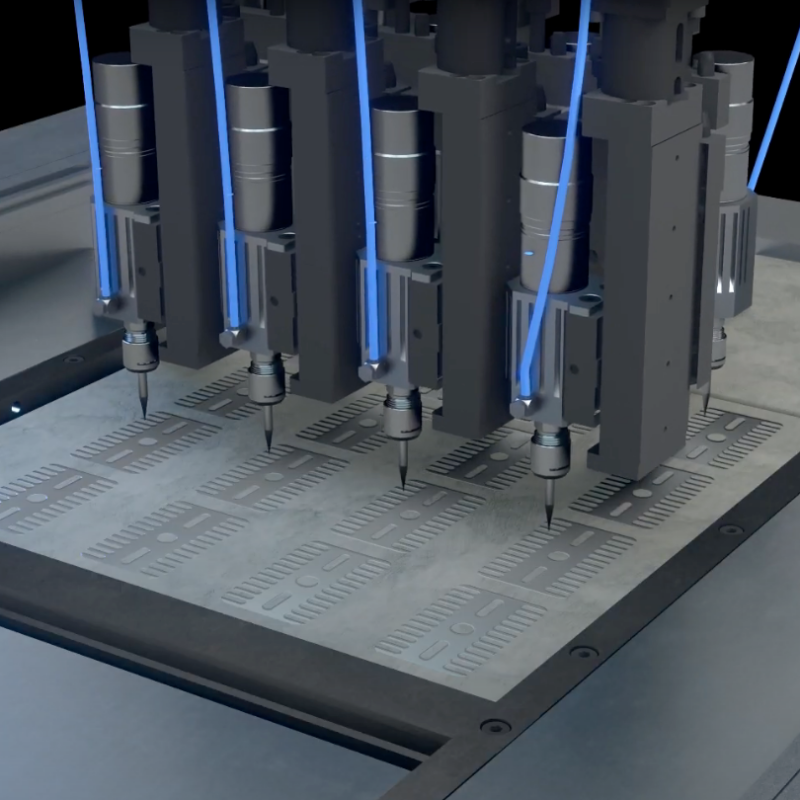

Our process is built specifically for high-quality, production-grade metal parts—not just one-off prototypes.

We use a proprietary platform that delivers:

- Smooth surface finish

- Tight tolerances

- Repeatable, scalable production quality

More importantly, we work with your team to:

- Review your full subassembly or CAD

- Identify real opportunities to consolidate

- Recommend the best mix of additive + off-the-shelf

- Build a plan that works in both design and production

This isn’t just printing.

It’s re-engineering the system—to build smarter, faster, and with fewer compromises.

The Bottom Line

Part consolidation is one of the clearest ROI paths in additive manufacturing—especially when your assembly is too complex, too costly, or too slow.

Let us take a look. Even one or two consolidated components can make the whole system better.