Use Additive Where It Performs — Use Off-the-Shelf Where It Doesn’t Have To

Not every part in your assembly needs to be printed. In fact, the smartest builds often combine just a few printed components with off-the-shelf hardware — keeping costs down while unlocking performance where it matters.

When to Print

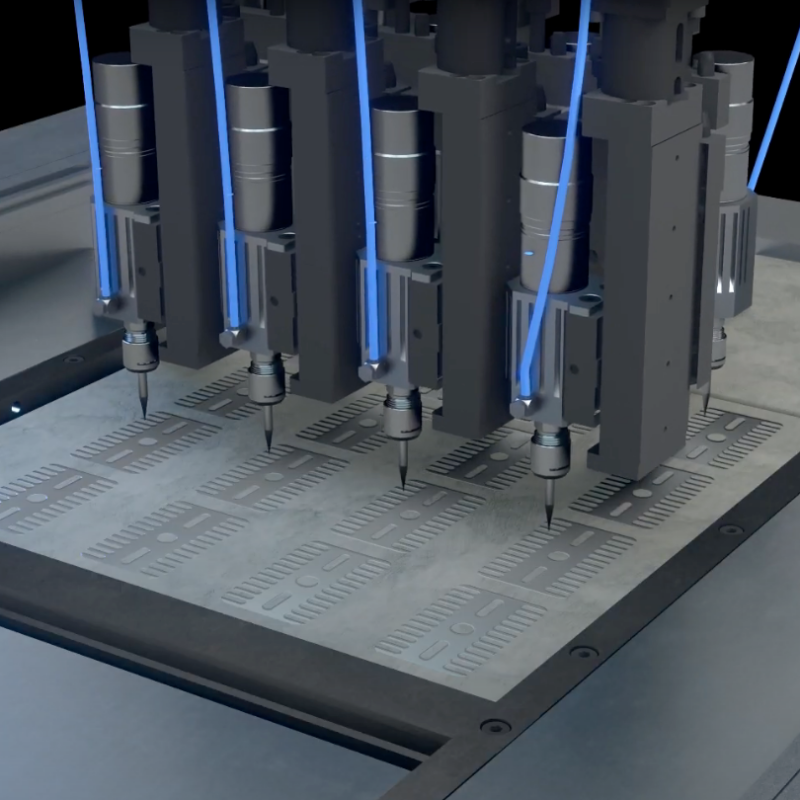

Use additive manufacturing when:

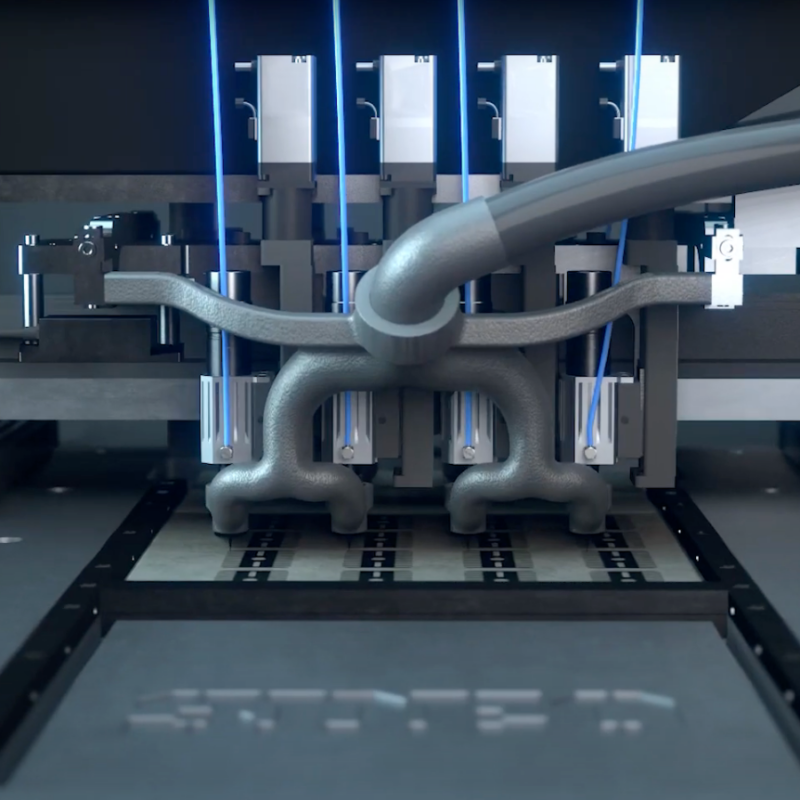

- You need internal geometry or channels

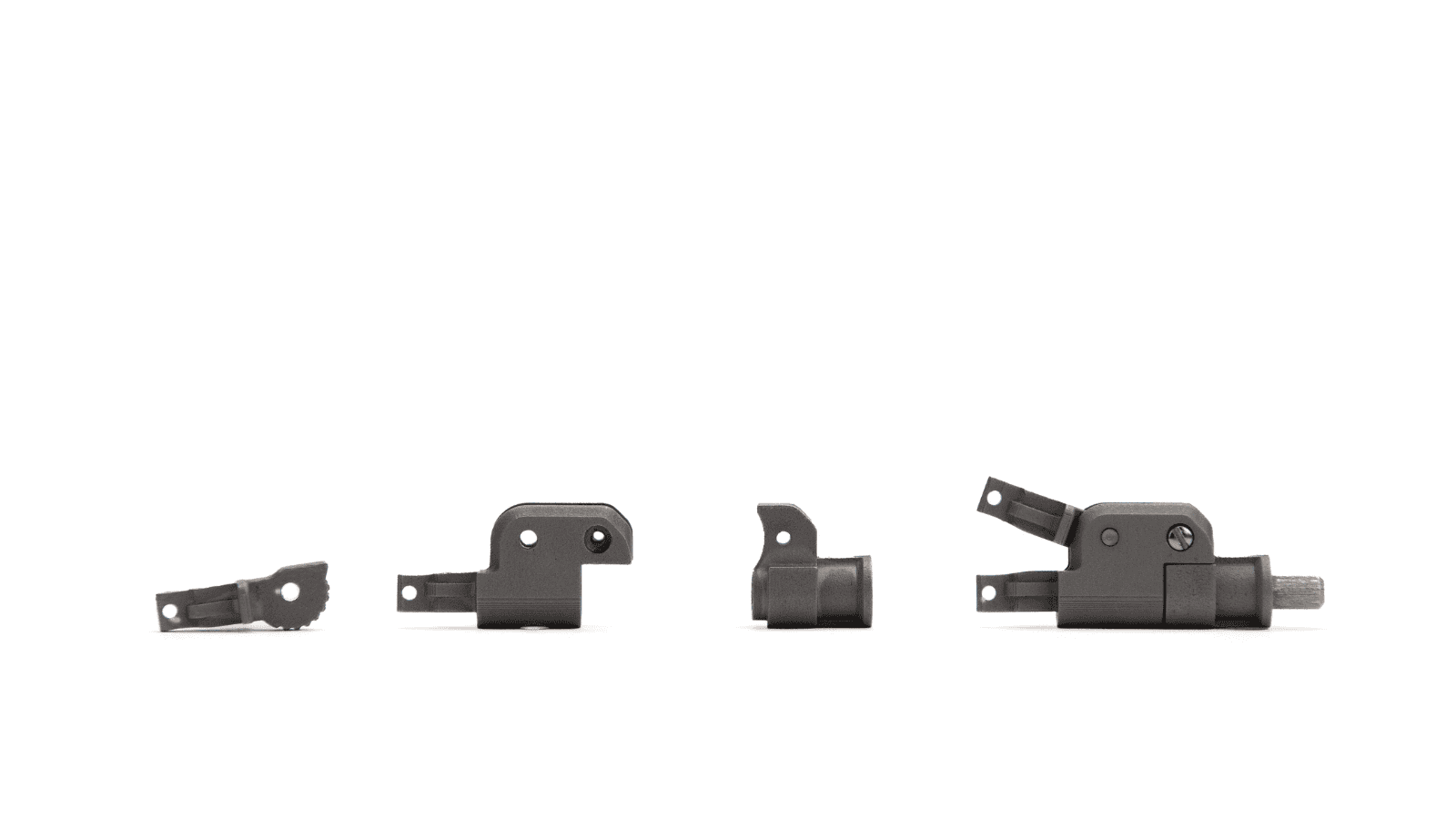

- You’re combining 3+ parts into one function

- You want to reduce assembly time or failure points

- You need fast delivery without tooling

- Geometry is unmachinable or not moldable

When to Buy Off-the-Shelf

Use COTS (commercial off-the-shelf) when:

- The part is purely structural or support hardware

- Geometry is simple and doesn’t affect performance

- You need thread inserts, bushings, or spacers

- It’s a standard size, spec, or catalog item

- Customization offers no clear ROI

How to Mix Them Smartly

- Let additive carry the complexity and function

- Use OTS for mounting, spacing, or sealing

- Design interfaces to accept standard components

- Reduce BOM size without over-customizing

- Build hybrid subassemblies with performance + scalability

Bonus Add-On: Mini “Review Checklist” Box

Quick Assembly Review Questions

- Can 3+ parts be replaced by one functionally?

- Are you aligning or fastening just to hold shape?

- Could internal geometry improve performance?

- Could this assembly be easier to scale with fewer parts?

Want the printable reference version?

Download our checklist for engineers exploring hybrid additive designs.