Even well-engineered assemblies can get out of hand. What starts as a clean mechanical design can become a headache to build, troubleshoot, or scale.

Here are five clear signals that your assembly might be costing more time, effort, and risk than it should—and how smart additive design can help.

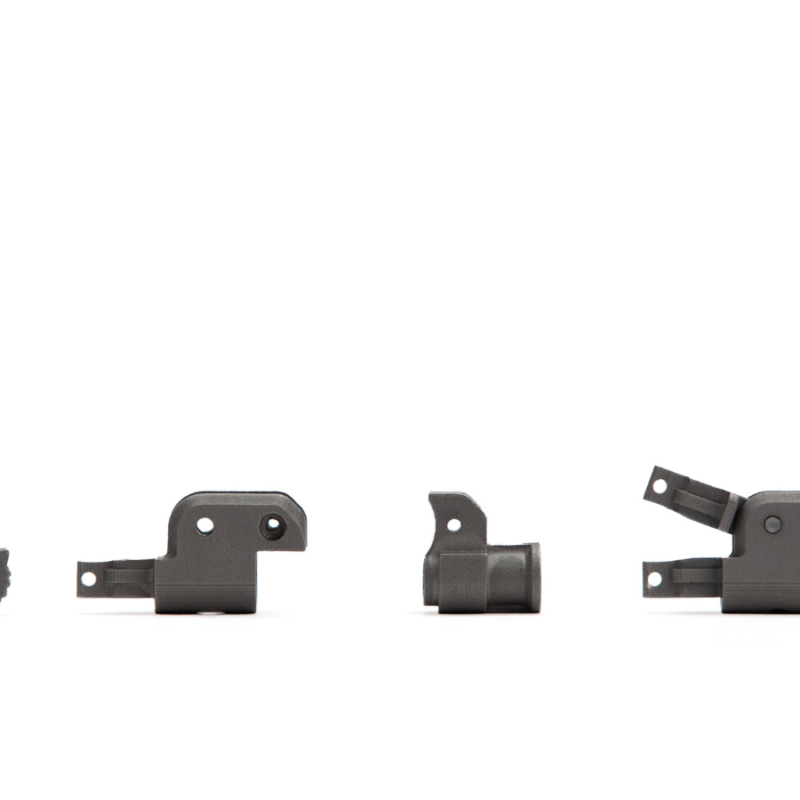

1. You’re Using Fasteners Just to Hold Geometry Together

Fasteners have their place, but when they’re used just to get around process constraints—like tool access or weldability—you’re adding unnecessary parts, weight, and failure points.

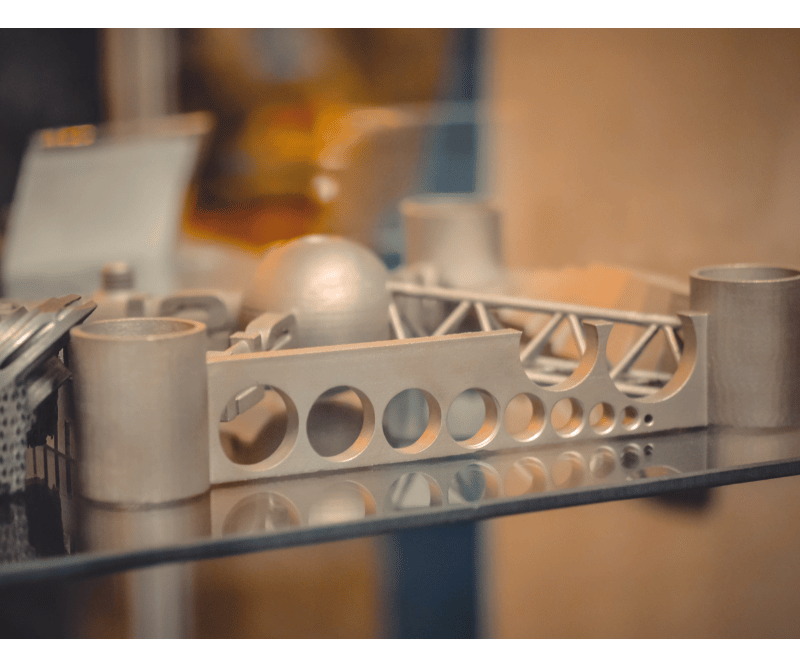

✅ Additive lets you combine multiple fastened parts into a single printed component, reducing build time and long-term wear.

2. Assembly Takes Multiple Alignments or Custom Jigs

If building your assembly requires custom tooling, technician-specific know-how, or tedious alignments, that’s not scalable—and it’s not reliable.

✅ Smart consolidation reduces reliance on jigs and manual steps, allowing better consistency at production scale.

3. You’re Stacking Tolerances Across Several Parts

Multiple interfaces = multiple opportunities for variation.

When tolerances from 3–5 parts stack up, even a small shift can throw off the whole system.

✅ Fewer parts means fewer interfaces to control—and better reliability across builds.

4. One Late Part Can Stall Your Entire Build

If your whole subassembly stops because of one backordered bracket or spacer, your BOM is likely too fragile.

✅ Additive lets you eliminate custom parts from your sourcing list, and often combine their function into something printable.

5. You Keep Troubleshooting the Same Failure Points

Are your connection points or alignment interfaces where things keep going wrong? That’s often a sign your assembly is fighting its own design.

✅ By consolidating around performance—not just process—you can eliminate weak spots altogether.

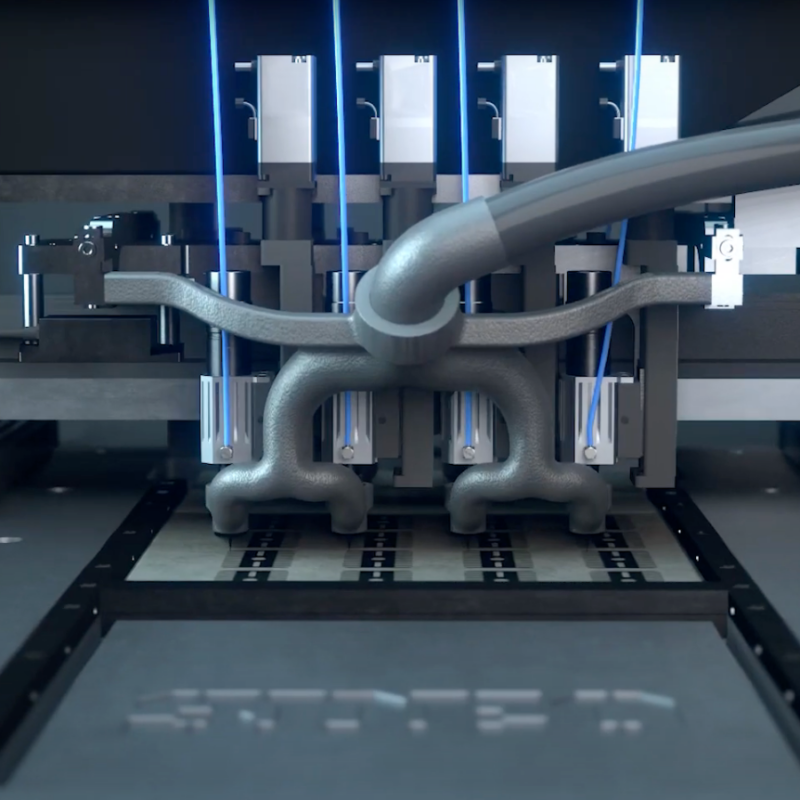

Ready to Rethink the Build?

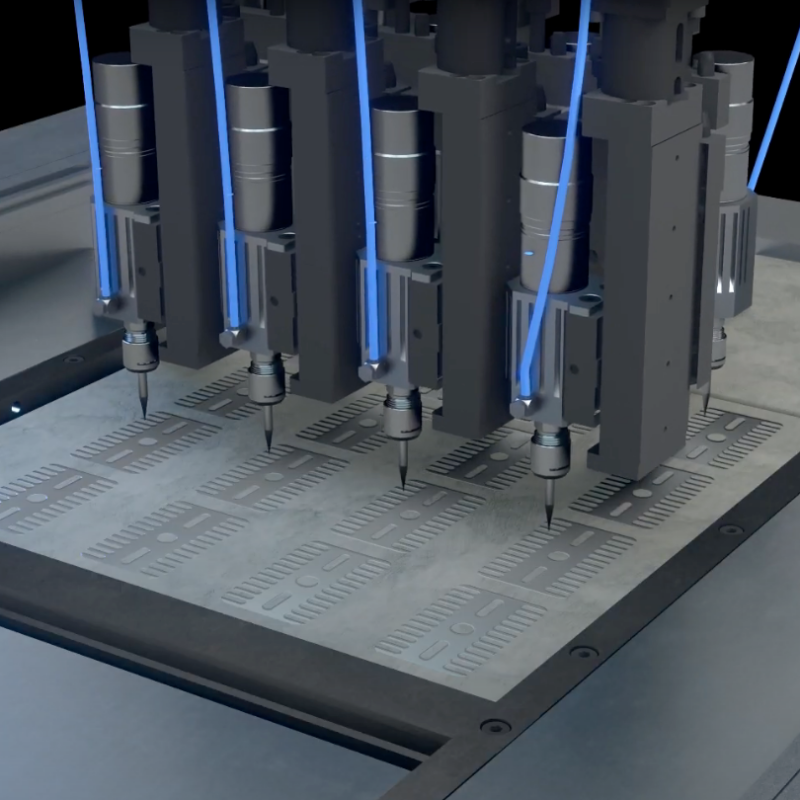

At 3DEO, we help engineers simplify subassemblies using a mix of:

- Additive components (for what you can’t machine or buy)

- Off-the-shelf hardware (for what you don’t need to reinvent)

- Engineering support to make it manufacturable and repeatable

Start a design review — and let’s take a look together. You may be 2 printed parts away from a dramatically better build.