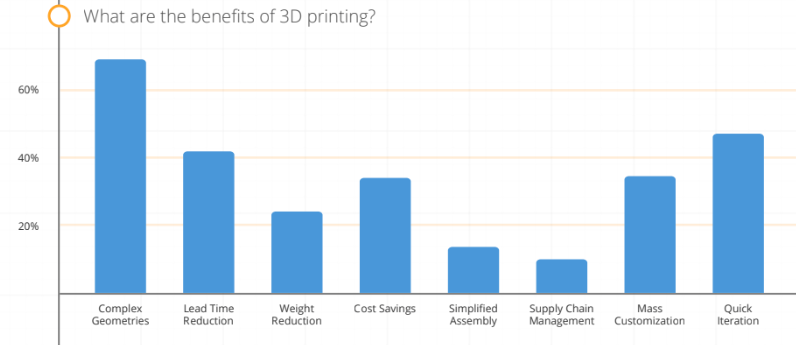

When people think of the benefits of 3D printing, they often think of complex geometries, quick iteration, and short lead times. But many are now realizing that 3D printing can be a huge cost saver when its done right.

According to Sculpteo’s State of 3D Printing 2019, nearly 40% of the respondents cited cost savings as a key benefit of 3D printing. 3D printing can be a huge cost-saver for those who need complex, low-to-medium volume components.

3DEO, in serial production with many customers today, is proving cost savings are a real possibility.

Cost of Traditional vs. Additive Manufacturing

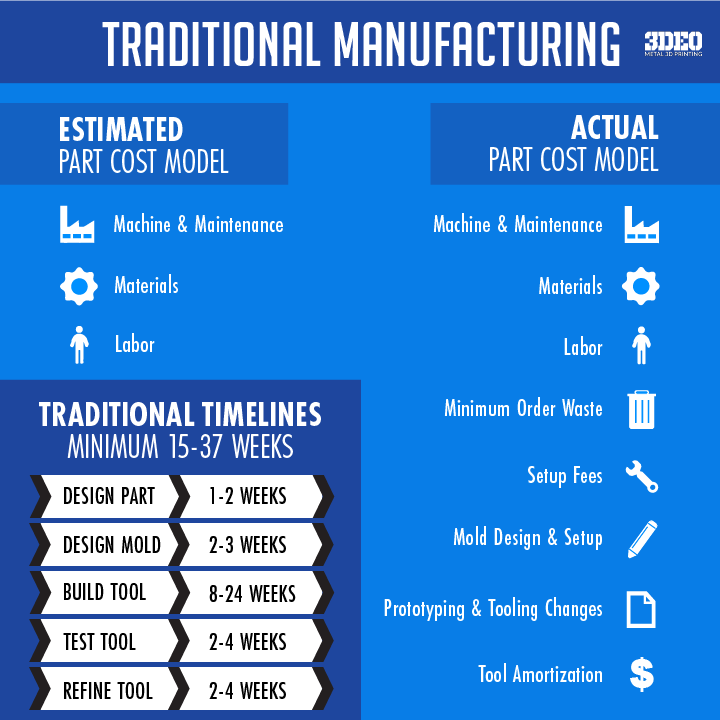

Machine, material, and labor are the usual suspects when considering the costs associated with traditional manufacturing. However, there are additional costs that are often not factored in by customers, which include tool amortization, prototyping and tooling change, mold design and setup, setup fees, and minimum order quantities.

When it comes to traditional vs. additive manufacturing, one of the best benefits of 3D printing is zero tooling costs. You can get started with 3D printing immediately with only a CAD model. An infinite number of geometries are possible and design changes are as easy as updating the CAD model. There are no mold or setup fees which eliminates tooling costs completely.

Many traditional manufacturing processes such as metal injection molding justify the high cost of tooling by requiring high volume blanket POs or large minimum order quantities (MOQ). MOQ lock customers into a design and amortize the cost of tooling over time. For example, if tooling cost $100,000, then a 100 piece order will be $1,000 per piece. But a 1,000,000 piece order will cost $0.10 per piece, which can be much easier for a customer to bear. For a large production order, traditional manufacturing can be more affordable than additive manufacturing. But for low to medium volume orders, additive manufacturing may actually the best choice. It depends on a variety of factors, but over time 3D printing is becoming more and more cost competitive.

3DEO Lower Risk By Eliminating Up-Front Tooling Costs

Many 3D printing companies focus on achieving the most complex designs and short lead times. But what happens when cost savings becomes the #1 benefit of 3D printing? What differentiates 3DEO from other companies is that we are already cutting the cost curve and competing on price with CNC machining and metal injection molding.

3DEO’s Intelligent Layering technology is uniquely designed to be low-cost. By specializing in small complex metal components, 3DEO can make affordable parts at the volume that our customers need. In addition to no tooling or upfront cost, 3DEO’s superior post-print surface finish dramatically reduces the cost of post-processing. Post-process or secondary operations make up 50% of the cost of 3D printing. By achieving an excellent surface finish as-printed, 3DEO is able to significantly save the customer on secondary operations.