The additive part of the name comes from adding layer upon layer to create the part, as opposed to subtractive technologies such as CNC machining which mill and grind away material to reach a final part. How these additive layers are formed and the parts are created is what separates the different additive manufacturing technologies. Some processes use a heat source to immediately turn the feed material into solid metal, and others create parts with metal powder that are first bound in a “green” state and later placed in a sintering furnace to achieve final part density. Regardless of how these layers are ultimately created, the AM process of building one very thin layer after another has a significant number of advantages to traditional manufacturing.

The additive part of the name comes from adding layer upon layer to create the part, as opposed to subtractive technologies such as CNC machining which mill and grind away material to reach a final part. How these additive layers are formed and the parts are created is what separates the different additive manufacturing technologies. Some processes use a heat source to immediately turn the feed material into solid metal, and others create parts with metal powder that are first bound in a “green” state and later placed in a sintering furnace to achieve final part density. Regardless of how these layers are ultimately created, the AM process of building one very thin layer after another has a significant number of advantages to traditional manufacturing.

This article is part of 3DEO’s Guide to Metal Additive Manufacturing. Subscribe to our email list to stay current on all of our articles. The first article answers the question “What is additive manufacturing?” and provides a general introduction to AM and its benefits.

New metal additive manufacturing processes are constantly being developed, but today most can be divided into six categories:

Powder Bed Fusion – DMLS, SLS, SLM, LMF, DMP, EBM

Powder Bed Fusion is a popular technique for metal additive manufacturing and includes two main technologies: Laser Sintering and Electron Beam. These techniques are grouped together since they each begin with a layer of metal powder being rolled onto the build tray, and then an energy source (laser or electron beam) fuses or melts the powder into deliberate 2D designs. These 2D layers are fused on top of each other to create the 3D object. Electron beams produce more energy than lasers and are chosen to fuse the highest temperature metal superalloys for parts used in extreme conditions such as jet engines and gas turbines.

Binder Jetting

Binder Jetting is a powder bed process that utilizes inkjet technology and a binding agent. The liquid binder is used to “glue” the metal powder together within and between layers. A layer of metal powder is first rolled onto the build tray, and then an inkjet print head moves along the x and y axes and deposits binder in the shape of the part for each respective layer. After each layer is created, the build platform is lowered incrementally to make room for the next layer. The part being printed is supported within the powder bed by the unbound powder, which is then removed to complete the process. The result is a “green part” which then needs to be placed in a sintering furnace to achieve final part density.

Metal Extrusion

Metal extrusion in additive manufacturing is a fairly new process. Similar to the wildly popular plastic-based FDM process, filament is heated and drawn through a nozzle and then deposited layer-by-layer. This filament is a combination of thermoplastic material and metallic particles. The nozzle moves in the x and y axes across the part for a given layer. The build platform then lowers to make room for new layers. After the part is complete, it is placed into a sintering furnace to burn out the remaining plastic and sinter the metal particles together. Extrusion-based additive manufacturing has been widely used for plastics and polymers, but only recently has developed to create metal parts. Fused Deposition Modeling (FDM) is the name for the plastic extrusion process which was originally patented by Stratasys. Similar to binder jetting, the patent expired several years ago and the market saw

Directed Energy Deposition (DED)

Directed Energy Deposition (DED) is an additive manufacturing process where metal wire or powder is combined with an energy source to deposit material onto a build tray or an existing part directly. Parts chosen for DED are typically large without the need for tight tolerances. DED methods are capable of building very large parts and are popular because of the rapid deposition speed. Because it closely resembles welding, DED is commonly used to repair and maintain existing parts. DED machines usually mount a nozzle on a multi-axis arm, which then deposits the metal feedstock to the surface. When used with 5 or 6 axis machines, the material can be deposited from nearly any angle and is melted upon deposition with a laser or electron beam. This process means DED can be used to build objects very quickly and is only limited in size by the reach of the robotic arm.

Material Jetting

Material Jetting is relatively new and similar to binder jetting, with one key difference — instead of a binder being jetted through the printhead, a metallic material is jetted. This material is jetted onto the build tray directly using either a continuous jetting or Drop on Demand (DOD) process. The jetted metal is deposited on the build tray in the cross section of the part for that layer. This process continues as it builds up layer after layer. The resulting part still needs to be sintered in a furnace to achieve final part density. Previously, material jetting was limited to plastics and polymers, but recent advances have seen new companies attempting to commercialize the process for metals. XJet currently shows the most promise for material jetting with its patented NanoParticle Jetting technology and recently shipped its first commercial machine to a customer.

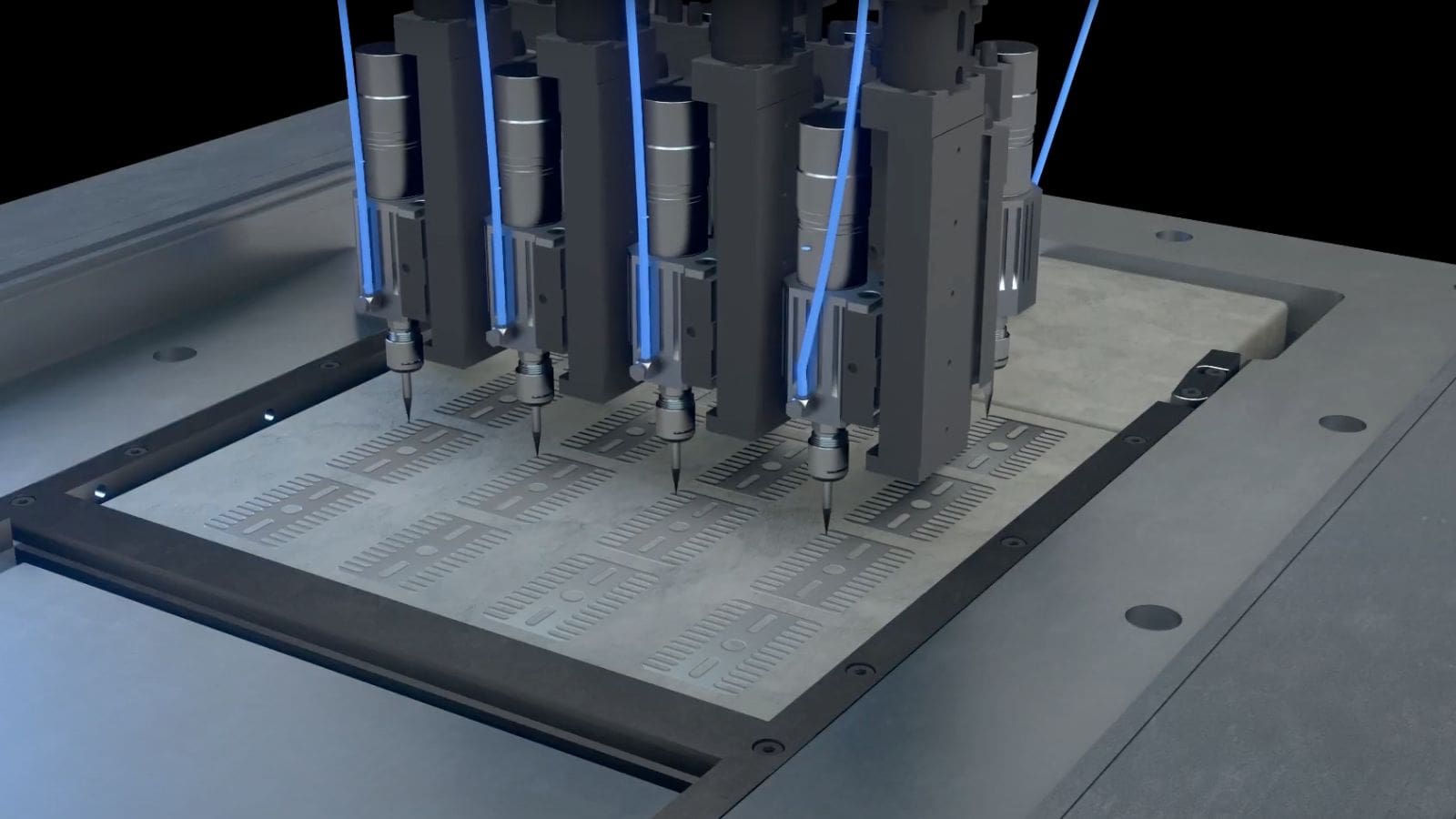

Intelligent Layering®

Intelligent Layering® is a new additive manufacturing process developed by 3DEO that enables medium-to-high volume metal part production. The process begins by spreading a thin layer of metal powder onto a build tray, and then uses a spray system to apply binder over the entire layer. A micro end mill is then used to cut into the bound powder at the perimeter of all layer features. From then on, the process is a layer-by-layer CNC operation until a precision green part is created. The green part is then sintered in a furnace to achieve final part density of 99% or greater. Intelligent Layering® unlocks the potential for high volume metal AM with a highly repeatable process that produces low-cost metal parts.

Work with 3DEO

3DEO makes high quality metal components with our proprietary metal 3D printers. We specialize in manufacturing low/medium volumes on demand, which means there’s no need to worry about long lead times, minimum order quantities, or high tooling/setup costs.

{{cta(‘8e2d4675-7c44-4d4b-99af-c8ef1aa04dce’)}}