How long does 3D metal printing take? The answer is that it varies based on the use case and circumstance. However, 3D metal printing is significantly faster than traditional metal casting, especially for creating prototype parts.

Let’s explore the various factors that can affect the printing time of 3D metal objects.

From the speed and efficiency of the printer to the complexity of the design, each element plays a crucial role in determining the overall print time. The duration of the 3D printing process can be influenced by various factors, including the size and scale of the object, the type of material used, the thickness of the layers, and the required post-processing steps.

Key Takeaways

- Technological advancements and cost are significant factors affecting 3D metal printing time.

- Printer speed and efficiency play a crucial role in reducing printing time and optimizing material usage.

- The complexity of the design, including intricate designs and material compatibility, affects the printing time.

- The size and scale of the object, along with the material and layer thickness, also impact the duration of 3D metal printing.

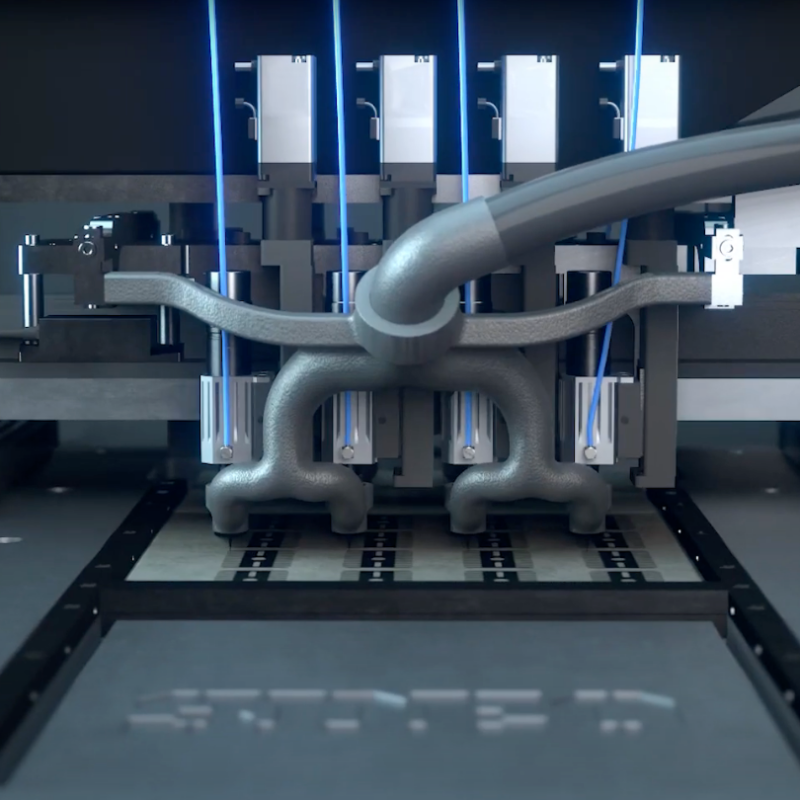

- 3DEO’s Intelligent Layering® technology provides the best of both worlds; the speed of 3D printing combined with the scalability of traditional production methods.

Factors Affecting 3D Metal Printing Time

There are several factors that can affect how long 3D metal printing takes. One such factor includes the advancements in 3D metal printing technology. As technology improves, the printing process becomes more efficient and quicker. Newer printers have faster print speeds and can handle more complex designs, reducing the overall printing time.

In addition to technological advancements, cost plays a large factor in determining print times in 3D metal printing. Higher costs may lead to longer print times as companies may prioritize other projects or limit the use of expensive materials. On the other hand, lower costs may result in faster printing times as companies have more resources available.

Overall, the continuously evolving landscape of 3D printing and the associated production costs significantly influence the length of time of the metal 3D printing process.

Printer Speed and Efficiency

Printer speed also plays a crucial part in determining the duration of the printing process. Faster printers can produce parts more quickly, which is especially beneficial for large-scale production. However, it is important to maintain printer accuracy while increasing speed. Striking a balance between speed and precision is necessary to ensure high-quality prints.

Efficiency is another important consideration when choosing a printer. An efficient printer optimizes material usage and minimizes waste, leading to cost savings. Conducting a cost analysis is essential to determine the most efficient printing strategy. Factors such as material costs, labor costs, and energy consumption should be taken into account.

By considering both printer speed and efficiency, you can make informed decisions to streamline the 3D metal printing process.

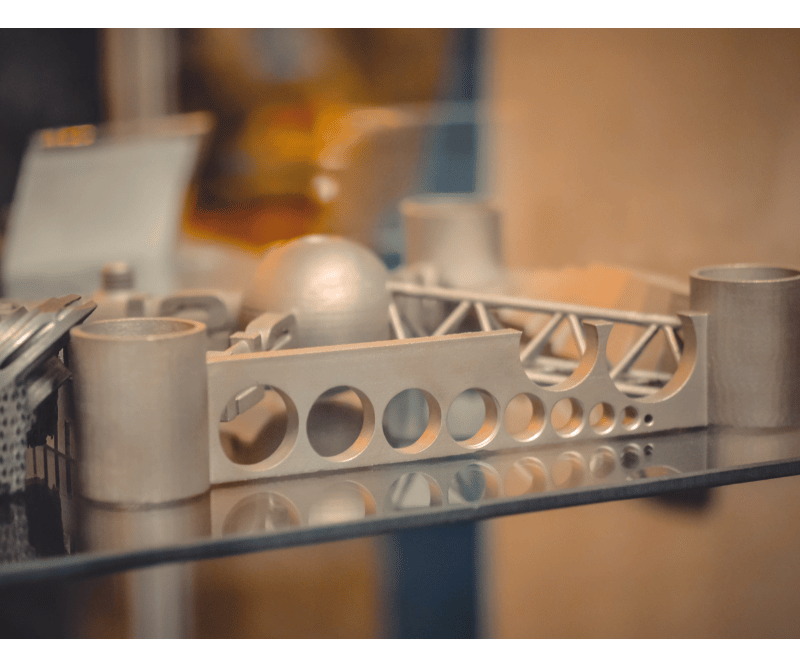

Complexity of the Design

The complexity of the design can enhance the excitement and creativity of the 3D metal printing process. Design optimization plays a crucial role in determining productiontime–the more intricate and detailed the design, the longer it may take for the printing process to complete. This is because complex designs require more layers to be printed, resulting in a longer overall printing time.

Material compatibility is another factor that influences the printing duration. Certain materials may require specific printing parameters, such as temperature and speed, which can affect the overall printing time. As such,it is important to consider the complexity of the design and ensure material compatibility for a successful and efficient 3D metal printing process:

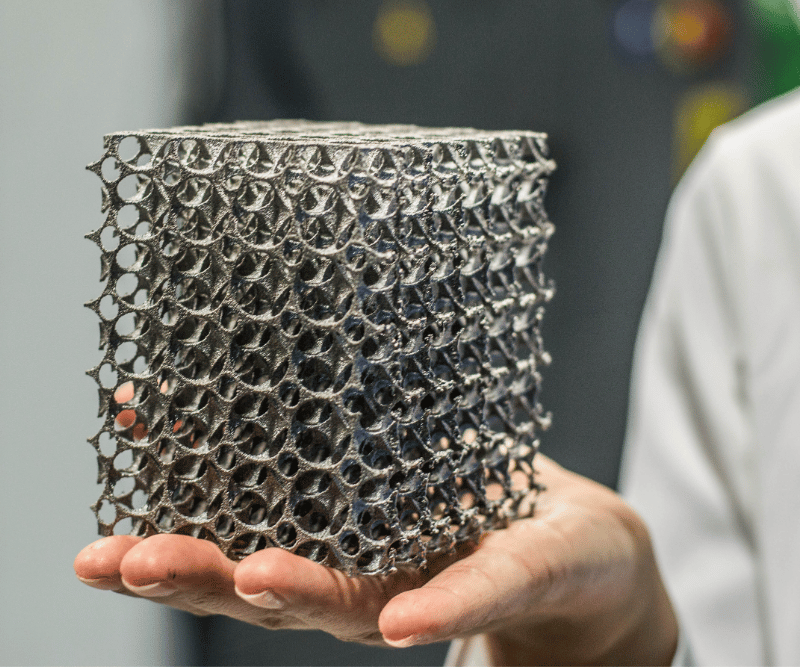

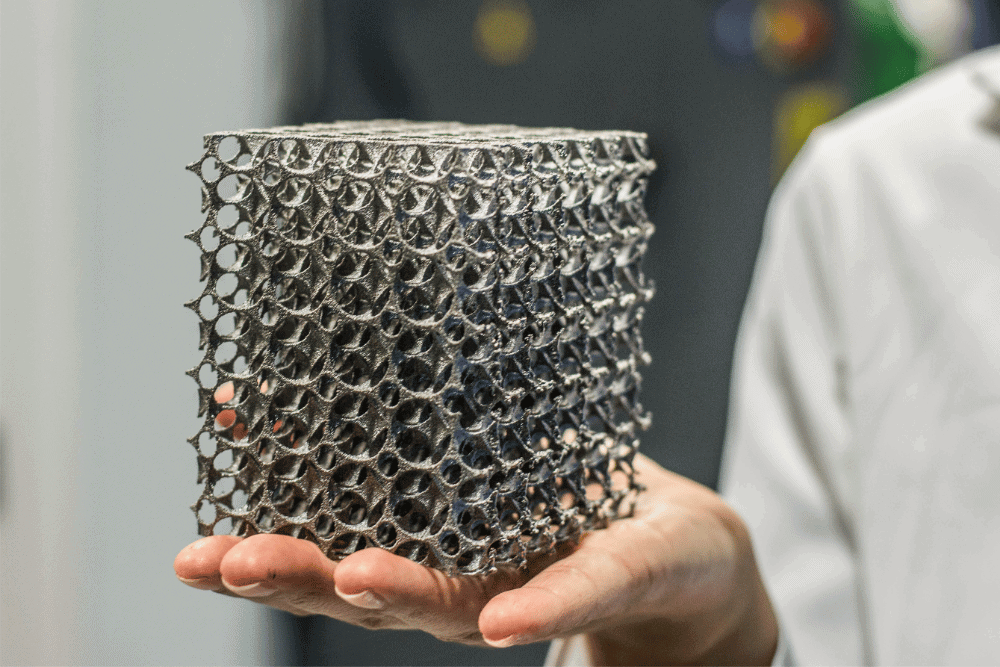

– Elaborate lattice structures that intertwine and create a mesmerizing pattern.

– Delicate and intricate filigree designs that showcase the precision of the 3D printing process.

– Organic and fluid shapes that defy traditional manufacturing methods.

Size and Scale of the Object

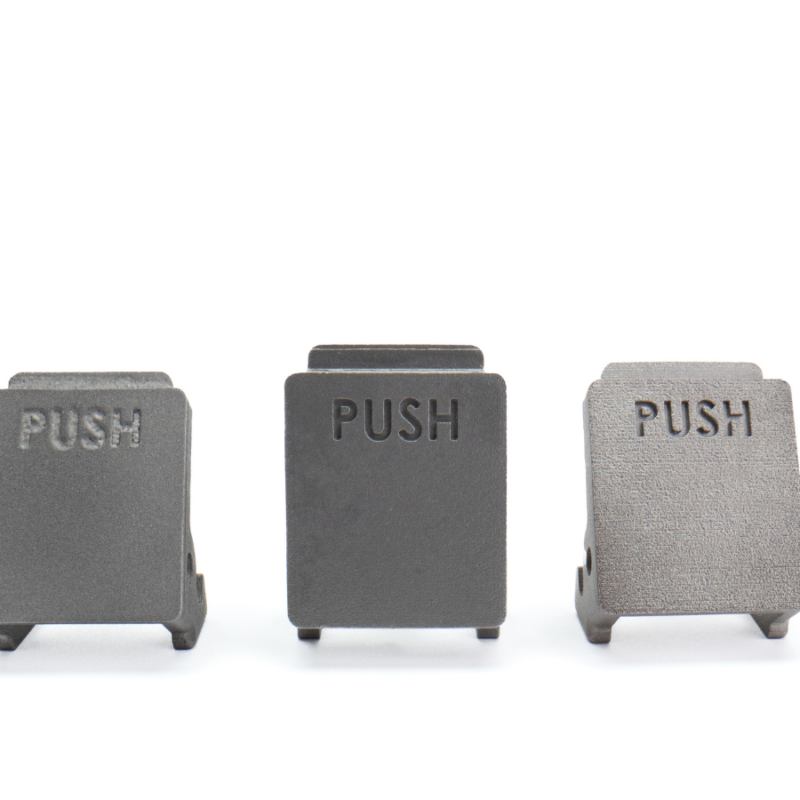

When it comes to the time required for 3D metal printing, the size and scale of the desired print play a significant role. Larger parts naturally require more time to print compared to smaller ones. Additionally, the type of 3D metal printer being used and the specific metal material being printed also affect the printing time.

While smaller objects can be printed relatively quickly, larger and more intricate designs can take several hours or even days to complete. If you’re planning to print a large-scale metal object, be prepared for the printing duration to be significantly longer.

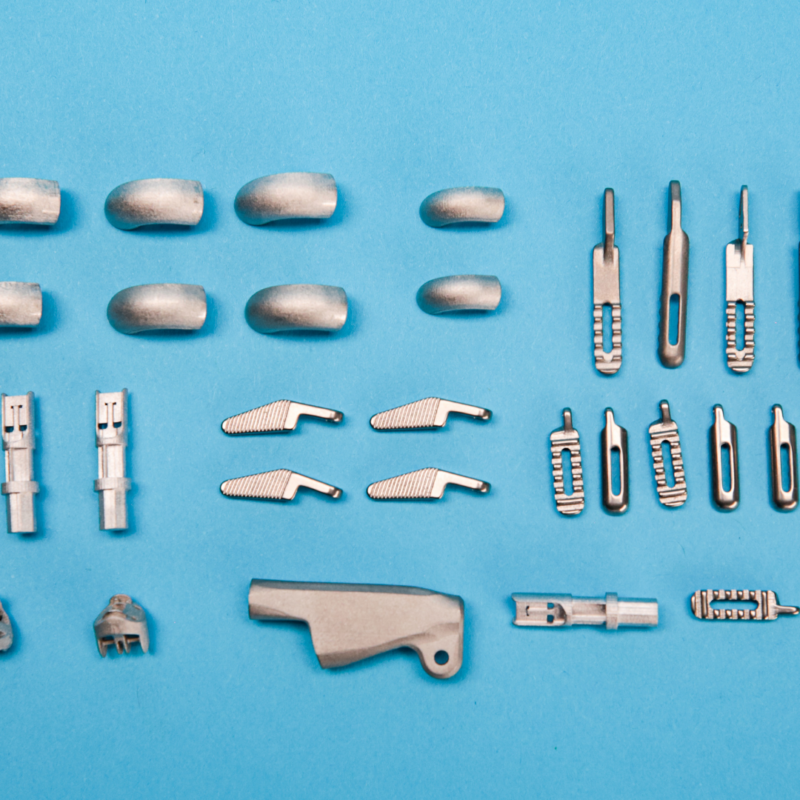

Material and Layer Thickness

In 3D metal printing, the choice in material and layer thickness allow for large-scale production of highly intricate designs.

At the same time, the choice of material and layer thickness directly affects the print quality and accuracy of the final product. When printing with metal, it is important to consider the material properties such as strength, durability, and heat resistance. Different materials require different printing settings and may affect the overall time it takes to print.

Additionally, the layer thickness chosen can impact the print time as well. Thicker layers may reduce print time but sacrifice print quality. On the other hand, thinner layers result in higher print quality but longer print times. It is essential to find a balance between print quality and affordability, as printing large-scale metal objects can be costly.

Post-Processing Time

Once you finish printing a large-scale metal object, you’ll need to allocate ample time for post-processing to ensure a smooth and polished final product. Post-processing involves various steps such as:

– Removing support structures

– Sanding

– Polishing

– Heat treatment

Post-processing times can vary depending on the size and complexity of the object, as well as the desired level of finishing. However, there are ways to reduce post-processing time and optimize printing time.

One method is to design the object in a way that minimizes the need for support structures, which can save time during the removal process. Additionally, using high-quality printing parameters and techniques can result in a cleaner print, reducing the amount of post-processing required.

By carefully considering these factors, you can streamline the post-processing phase and achieve a faster turnaround time for your 3D metal printed objects.

How Long Does 3D Metal Printing Take?

Learn more about how long your next 3D metal printing project may take as well as 3DEO’s proprietary Intelligent Layering® technology. Request a sample parts get, a quote, or contact us with any questions you may have.