Choosing the right metal Additive Manufacturing company for your next project can make all the difference in its success. In this guide, we will walk you through the key factors to consider when selecting a metal Additive Manufacturing company.

Firstly, it is important to assess the expertise and specializations of the company. Look for a company that has experience in your specific industry, works with your desired metal material, and understands the unique requirements of your project. They should have a proven track record of successfully completing similar projects.

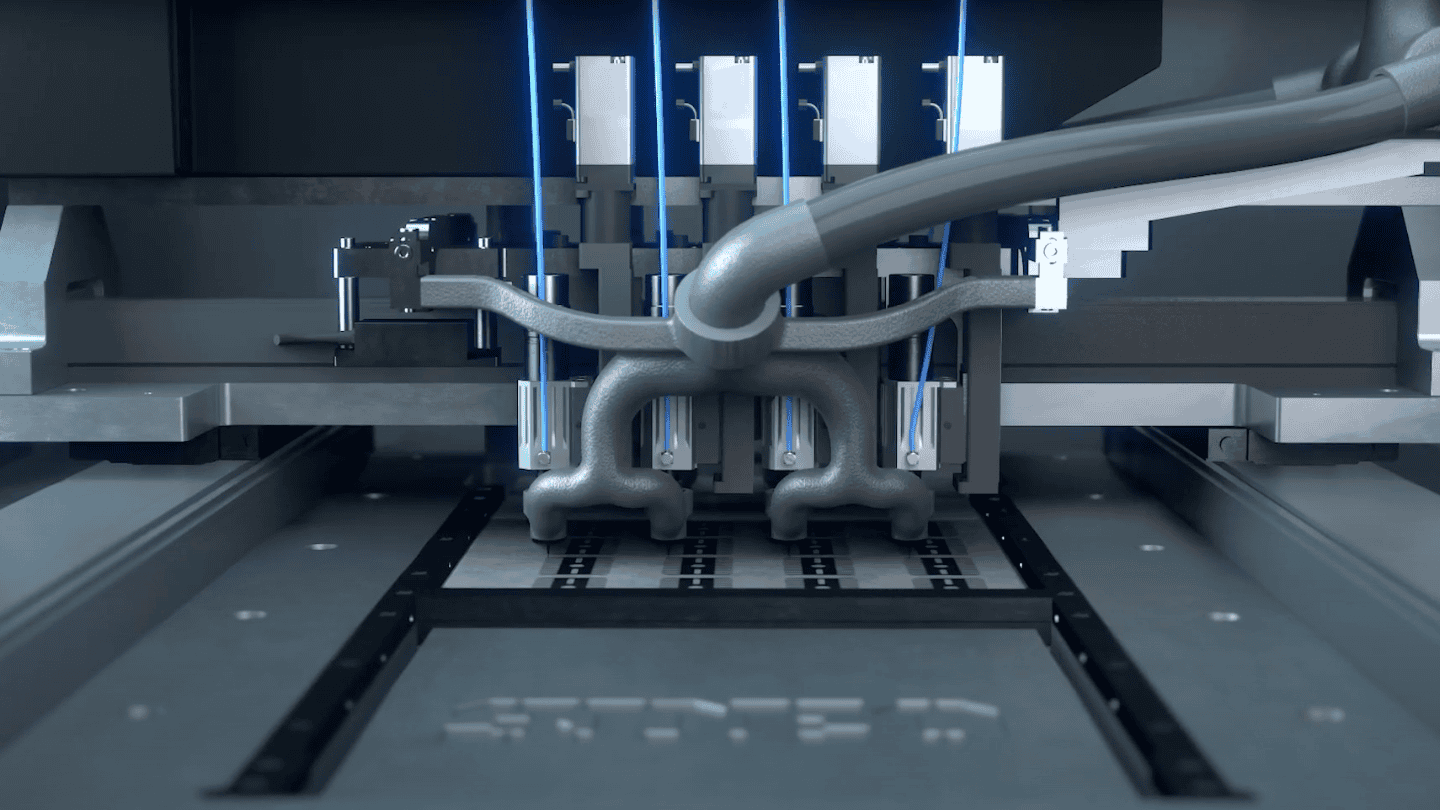

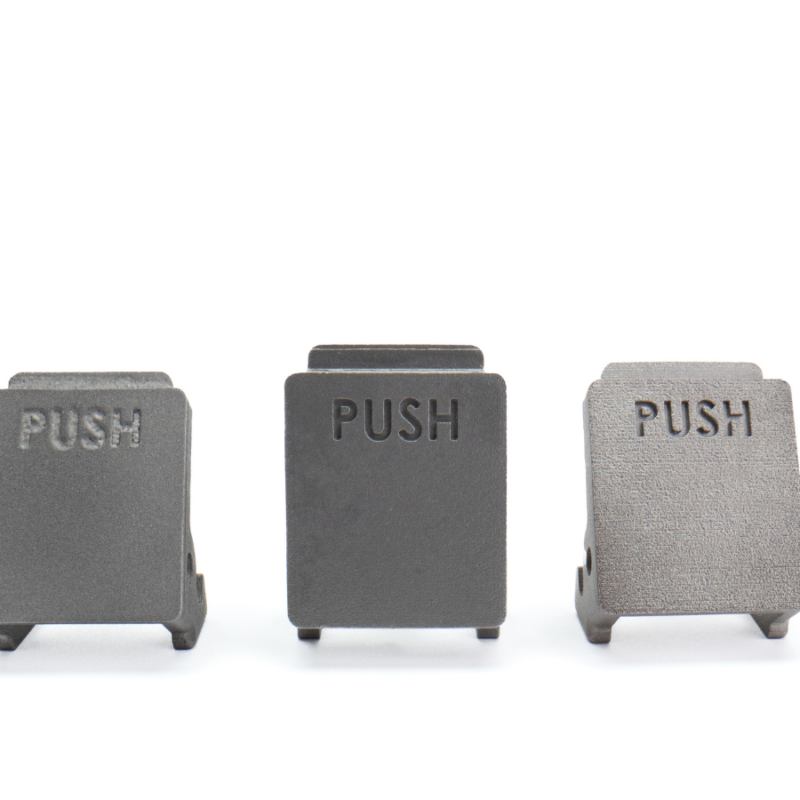

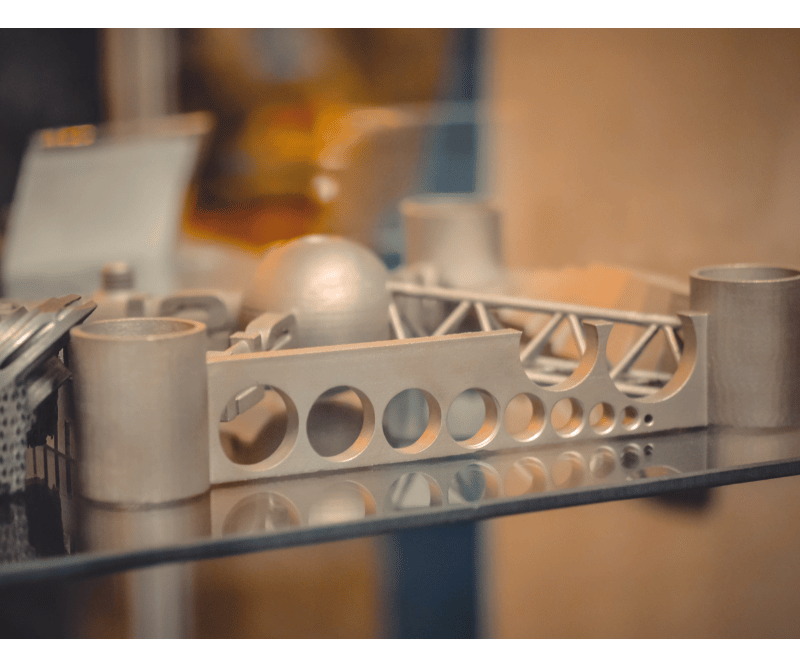

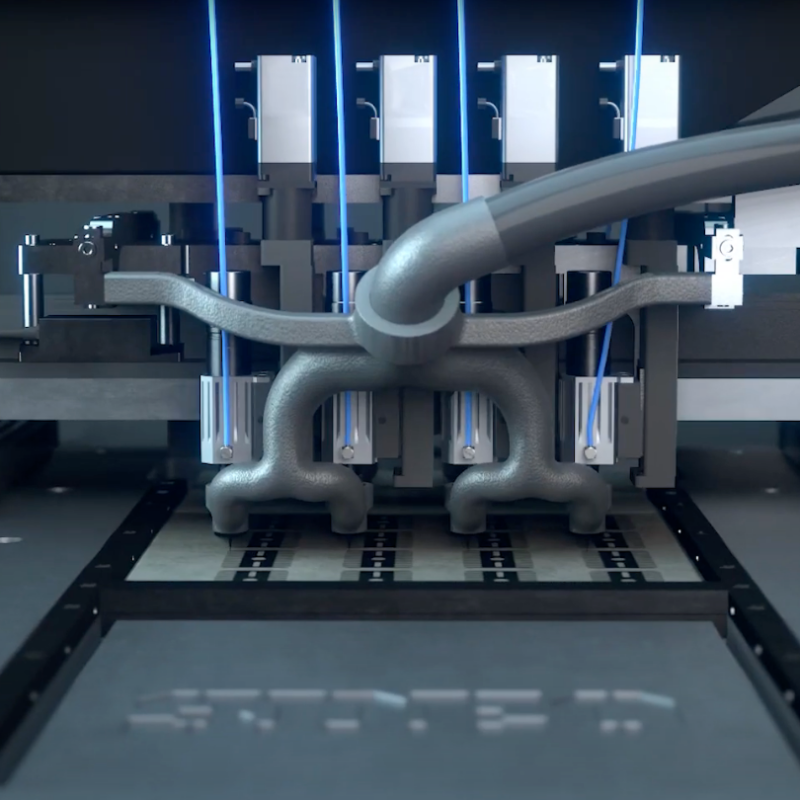

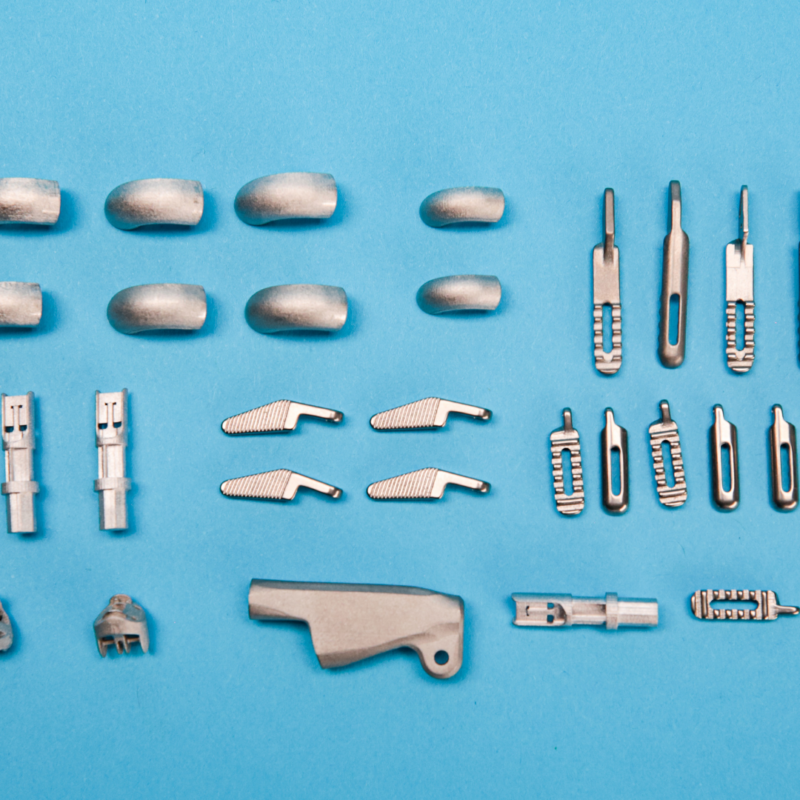

Next, evaluate the capabilities and equipment of the company. Make sure they have the necessary machinery and technology to not only build your project, but to produce your project at scale. Consider factors including the size and type of parts they can produce, as well as any additional services they offer, such as post-processing or finishing.

Reviewing the company’s track record and client testimonials is also crucial. Look for reviews and feedback from past clients to get an idea of their satisfaction with the company’s work. This will give you insight into their reliability, professionalism, and ability to meet deadlines.

Consider the company’s turnaround time and project management. Find out how quickly they can complete your project and if they have efficient project management processes in place. Clear communication and timely updates are important for a smooth and successful collaboration.

Examine the company’s pricing and cost transparency. Request detailed quotes and compare them with other companies to ensure you are getting a fair price. Look for a company that is transparent about their pricing structure and any additional costs that may arise during the project.

Lastly, check for quality control measures and certifications. A reputable metal Additive Manufacturing company should have strict quality control processes in place to ensure the highest standards of production. Look for certifications such as ISO 9001 to verify their commitment to quality.

By following these guidelines and considering these factors, you will be able to make an informed decision and find the right metal Additive Manufacturing company to bring your project to life.

Key Takeaways

- Experience and Expertise: Look for a metal Additive Manufacturing company with years of experience, specialization in the required metal material, a proven track record of successful projects, expertise in desired scale, complexity , design optimization, and familiarity with industry standards and certifications.

- Equipment and Technology: Ensure that the company has state-of-the-art Additive Manufacturing machines, the ability to work with the desired metal materials, advanced software for design and simulation, capabilities for post-processing and finishing, and investment in research and development for continuous improvement.

- Quality Control and Inspection: Choose a company that has robust quality control processes throughout the manufacturing process, uses non-destructive testing methods to ensure part integrity, complies with ISO and other quality standards, documents and traces all manufacturing steps, and collaborates with third-party inspection agencies for additional verification.

- Material Selection and Testing: Select a company with knowledge of different metal alloys and their properties, access to a wide range of metal powders for Additive Manufacturing, the ability to conduct material testing for performance and durability validation, collaboration with material suppliers for continuous material improvement, and expertise in handling and storing metal powders safely.

Assessing Expertise and Specializations

When choosing a metal Additive Manufacturing company, it’s crucial to assess their expertise and specialization to ensure they have the necessary skills and knowledge for your specific project.

Start by understanding their expertise in specific Additive Manufacturing technologies such as selective laser melting or electron beam melting. Look for companies that have a proven track record, such as 3DEO, of experience in handling projects similar to yours in function, complexity, scale and any other critical aspects of your project.

Analyze their specialization in different industries or materials like aerospace, automotive, or medical. This specialization analysis will help you determine if the company has the necessary understanding and capabilities to fulfill your project requirements.

By thoroughly assessing expertise and specializations, you can confidently partner with the right metal Additive Manufacturing company for your project.

Evaluating Capabilities and Equipment

To fully appreciate the capabilities and equipment of a metal Additive Manufacturing firm, it’s important to consider the sophistication of their technology and depth of expertise. Here are two key aspects to consider when evaluating a company’s capabilities and equipment:

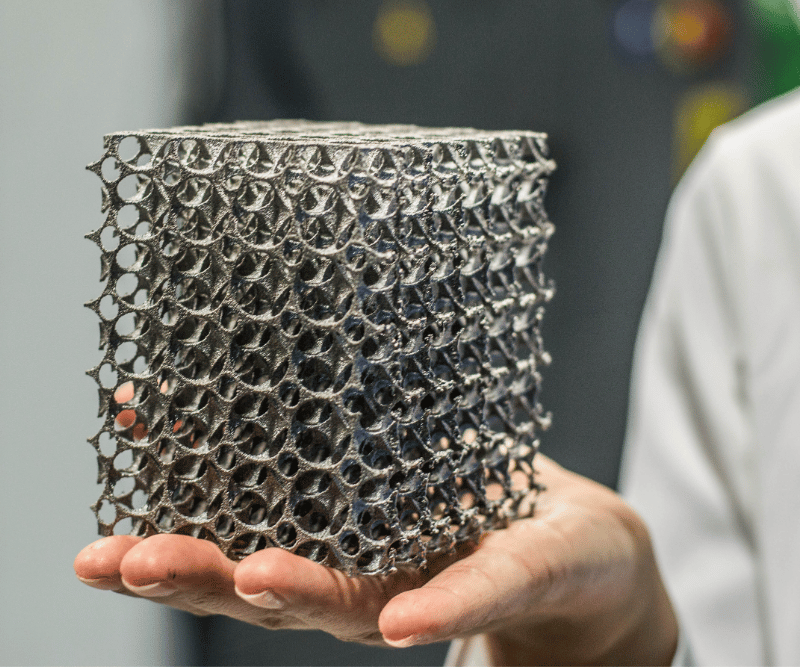

Process Optimization: Look for a company that emphasizes process optimization. This means they have a deep understanding of the Additive Manufacturing process and continually strive to improve efficiency and quality. Ask about their approach to process optimization and whether they have any specific strategies or technologies in place.

Material Selection: The ability to work with multiple materials is essential in metal Additive Manufacturing. Make sure the company has experience with the specific materials you require for your project. Inquire about their material selection and handling processes, including any testing or certifications they have for different materials.

By considering process optimization and material selection, you can ensure that the metal Additive Manufacturing company you choose has the capabilities and equipment necessary to successfully complete your project.

Reviewing Track Record and Client Testimonials

Take a moment to review the track record and client testimonials of the metal Additive Manufacturing firm you’re considering. You’ll gain a sense of how they work with customers and where they deliver the most value..

One of the most important qualities when selecting an Additive Manufacturing Partner is clear and open communication. An ideal additive manufacturing partner should effectively communicate with its clients throughout the project, ensure that all requirements are met and should promptly address any changes or concerns throughout the process. To best evaluate a company’s communication skills, make sure to review their track record and client testimonials to ensure a successful metal Additive Manufacturing experience.

Considering Turnaround Time and Project Management

Turnaround time and effective project management can greatly impact the success of your metal Additive Manufacturing experience.

When choosing a metal Additive Manufacturing company for your project, it is essential to consider their ability to deliver your parts within a reasonable timeframe. Look for a company that has a consistent track record of meeting deadlines and delivering high-quality results.

Communication efficiency is also key to ensuring that your project progresses smoothly. The ideal company will maintain open lines of communication, provide regular updates on the status of your projects, and keep you informed throughout the process, alleviating any potential issues efficiently and immediately.

Additionally, knowledgeable and accessible customer support is vital in addressing any concerns or questions that may arise. Choose a company that offers excellent customer support to ensure a positive experience from start to finish.

Examining Pricing and Cost Transparency

When it comes to pricing and cost transparency, it’s important to find a metal Additive Manufacturing partner that provides clear and upfront information. You want to work with a company that values transparency and understands the importance of competitive analysis and market research in determining pricing.

By conducting a competitive analysis, the company can assess the prices offered by other metal Additive Manufacturing providers in the market. This ensures that their pricing remains competitive and attractive to potential customers. Market research allows the company to understand the current trends, best practices and demands in the industry, enabling them to price their services accordingly.

A reputable metal Additive Manufacturing company will be able to provide you with a detailed breakdown of costs, including materials, labor, and any additional fees, ensuring that you have a clear understanding of the pricing structure before starting your project.

Checking for Quality Control Measures and Certifications

Ensure that the metal Additive Manufacturing provider you select has rigorous quality control measures and reputable, current certifications, guaranteeing the highest level of standards for your project. Here are three important items to consider:

- Analyzing material compatibility: The chosen company should have expertise in analyzing different metal materials and their compatibility with the Additive Manufacturing process. They should be able to recommend the most suitable materials for your specific project requirements.

- Ensuring regulatory compliance: It is critical to choose a company that follows all relevant regulations and industry standards. They should have certifications such as ISO 9001, indicating their commitment to quality control and compliance with regulatory requirements.

- Quality control measures: Look for a company that has robust quality control processes in place and a mindset of continual improvement. They should conduct thorough inspections and tests at various stages of the manufacturing process to ensure the final product meets your specifications and quality standards.

By considering these factors, you can ensure that the metal Additive Manufacturing company you choose will deliver high-quality, compliant, and reliable results for your project.

Choose 3DEO for Your Next Metal Additive Manufacturing Project

When choosing a metal Additive Manufacturing company for your project, it is important to carefully assess their expertise and specializations. Evaluating their capabilities and equipment will help ensure they have the necessary resources to meet your needs.

3DEO’s award-winning, cutting-edge technology has all the qualities you need to succeed in your additive manufacturing projects. From an extensive, proven track record with companies to implementing the most up-to-date certifications in creating proprietary technologies specifically to measure and enhance quality, 3DEO is an industry leader in additive manufacturing.

Ready to take your metal parts to the next level? Collaborate with 3DEO and tap into our expertise in designing, iterating, and producing complex metal components. Let’s co-create solutions that stand out in the industry.