Assemblies get complicated fast. What starts as a clean design can balloon into 10, 12, even 20 components — each with its own cost, lead time, tolerance stack, and failure risk.

But what if your 14-part assembly could be just 4 parts?

That’s not hypothetical — it’s exactly what we did for a recent customer.

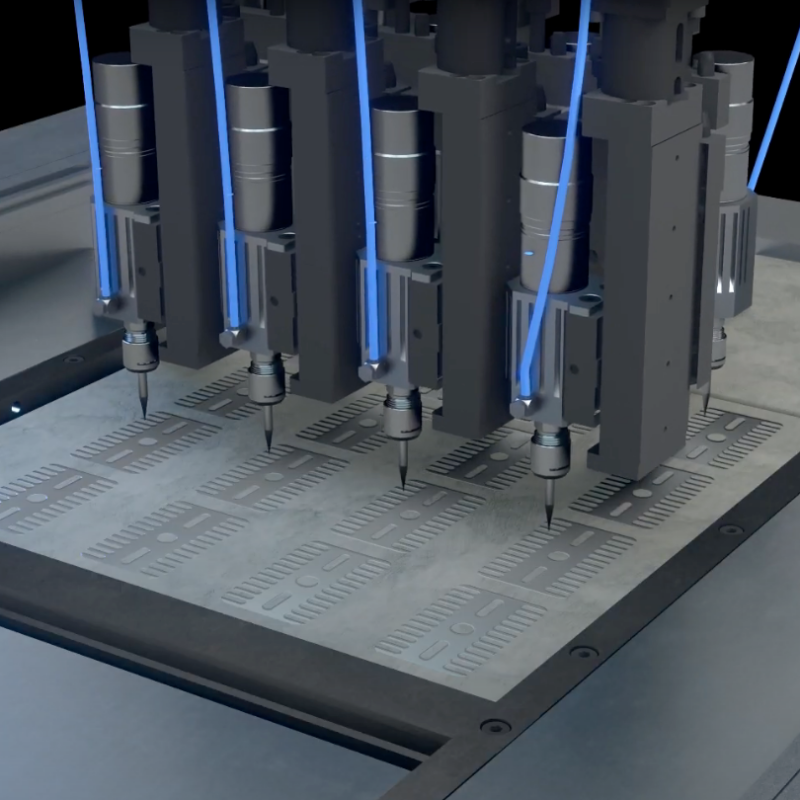

Additive manufacturing (AM), when applied strategically, lets you consolidate multiple components into fewer, smarter parts — simplifying everything from sourcing to assembly to long-term performance.

What’s Wrong With Complex Assemblies?

More parts means:

- More touchpoints

- More fasteners, welds, and alignments

- More variation

- More chances for something to go wrong

It also means:

- Higher cost

- More labor

- Slower builds

- Harder troubleshooting

- Delays when even one piece is backordered

You’re not just managing parts — you’re managing risk.

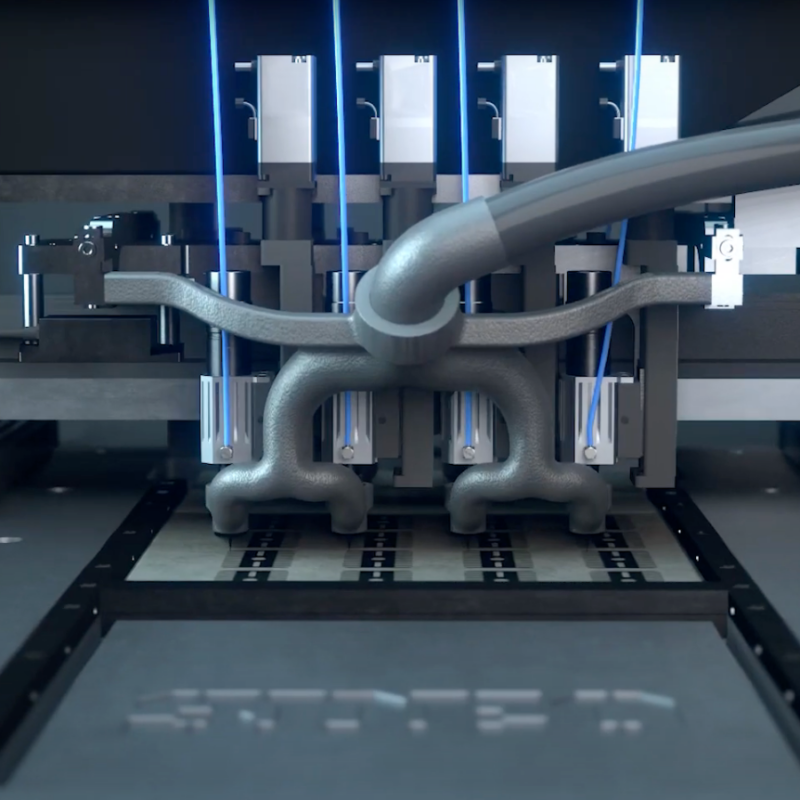

Where Additive Makes the Difference

Additive manufacturing changes the rules of what’s possible in part design. You’re no longer limited by:

- Tool access

- Mold complexity

- Multi-axis machining

- Separate operations for internal features

That means you can combine multiple parts into one printed component — often eliminating:

- Fasteners

- Brackets

- Precision alignment steps

- Redundant hardware

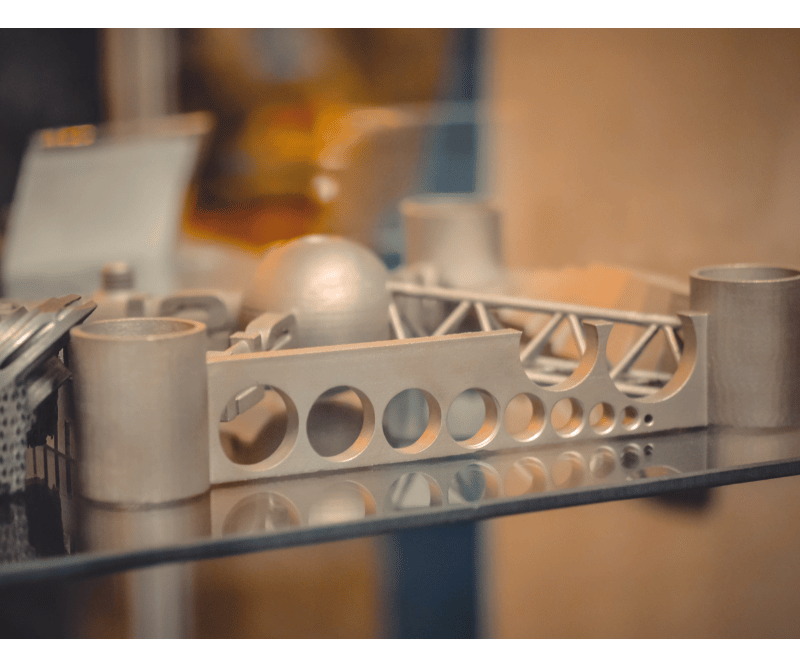

Real Example: From 14 Parts to 4

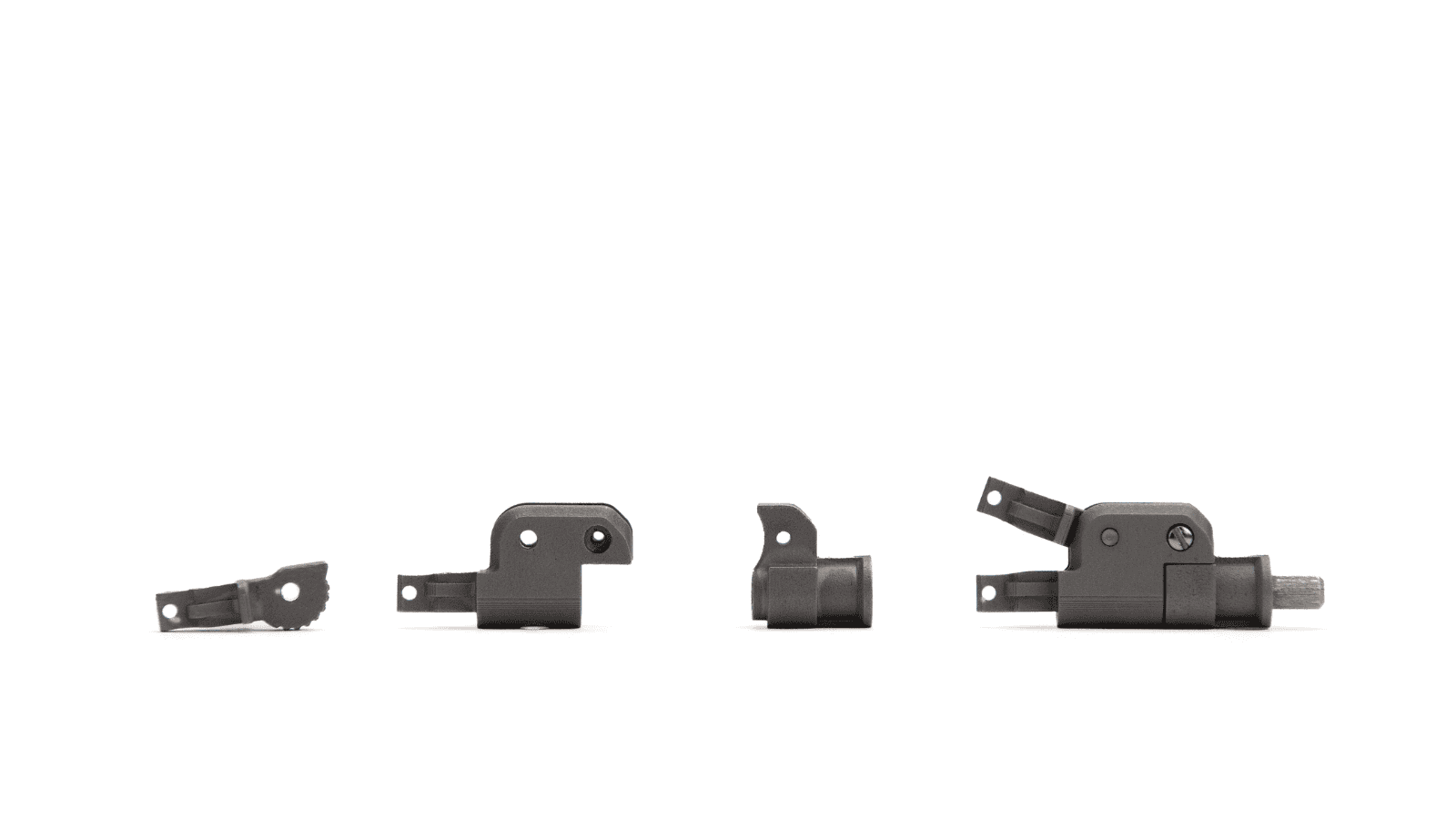

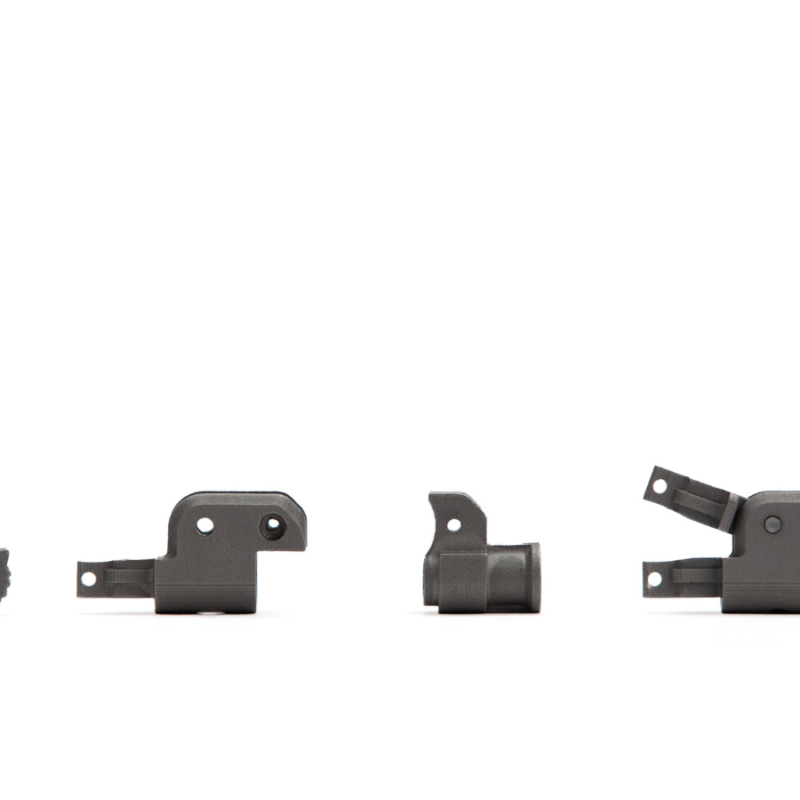

A rail OEM came to 3DEO with a 14-part subassembly that required manual alignment and hand assembly by a technician — a slow, error-prone process.

We reviewed the system and delivered a simplified version:

- 2 printed components (with internal geometry CNC couldn’t produce)

- 2 off-the-shelf parts

- All aligned and optimized for performance and speed

They cut build time, reduced cost, and hit their production goals faster — without sacrificing function.

Expert Tip:

Additive isn’t about printing every part.

It’s about printing the right parts — the ones that unlock real simplification.

When Should You Simplify?

You’re likely ready to consolidate if:

- You’re using 3+ fasteners to hold something together

- Multiple components could share the same geometry

- Your assembly requires manual fitting or custom tooling

- You’re troubleshooting recurring failures at connection points

The Bottom Line

Additive lets you think beyond how parts are made — and start thinking in terms of how systems should work.

At 3DEO, we don’t just print parts. We help you:

- Identify smart consolidation opportunities

- Combine AM with off-the-shelf components

- Deliver simpler, stronger, faster-to-build assemblies

Start a design review — let’s see how much we can simplify.