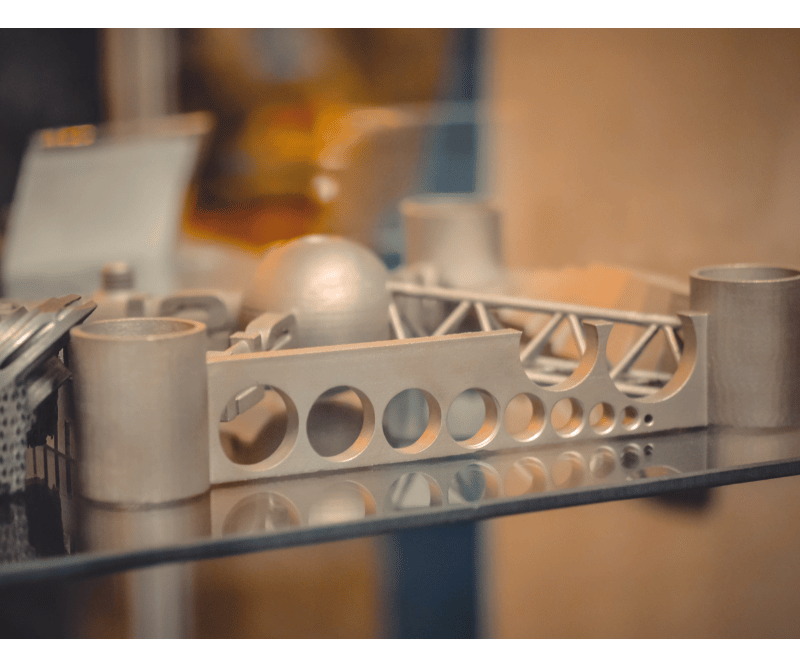

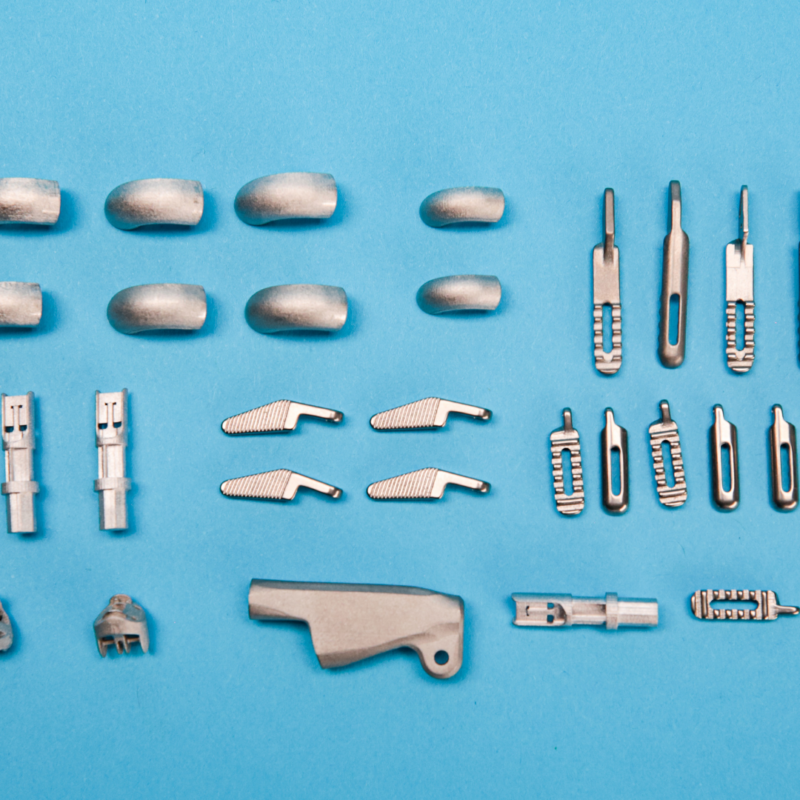

Modern metal 3D printing can utilize a range of metal additive materials to produce complex parts at scale for industries that range from medical to automotive and aerospace. 3DEO provides metal 3D printing with 17-4PH stainless steel, 316L stainless steel, and pure copper, some of the most commonly used materials for metal 3D printing with versatile applications.

Whether you are a designer, engineer, or simply an enthusiast, understanding the potential of these materials will give you a competitive edge in the 3D printing industry. By utilizing the proper metal additive materials, you can create intricate and durable objects that were once unimaginable.

From stainless steel to copper we will delve into the properties and benefits of each of the top metal additive materials in metal 3D printing. So, get ready to discover the wide range of possibilities that metal 3D printing offers!

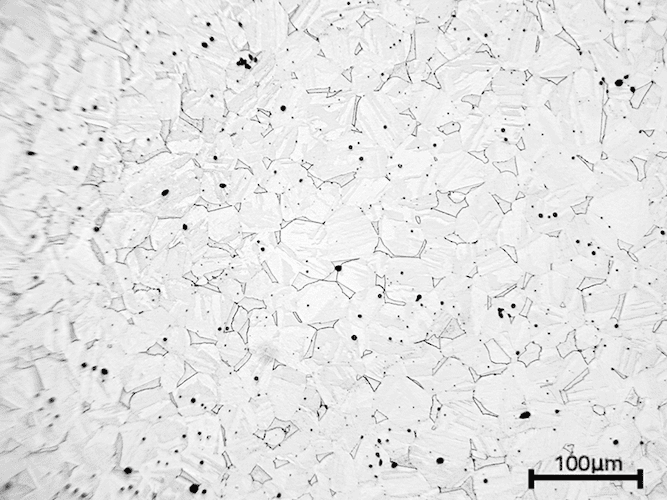

17-4PH Stainless Steel

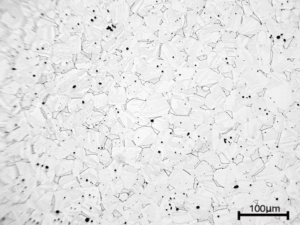

17-4PH stainless steel is a versatile and valuable material renowned for its exceptional combination of strength, corrosion resistance, and machinability. This precipitation-hardening stainless steel alloy offers several significant benefits across various industries.

First, its remarkable strength properties make it suitable for applications demanding high mechanical performance, such as aerospace components, industrial machinery, and medical instruments. This steel exhibits excellent resistance to corrosion in various environments, including those with exposure to chemicals, saltwater, and atmospheric conditions, reducing maintenance costs and enhancing product longevity.

The 17-4PH alloy’s unique precipitation hardening capability allows for heat treatment to achieve different strength levels, granting engineers the flexibility to tailor its properties to specific project requirements. Its machinability is another advantage, as it can be easily fabricated into intricate shapes and components, reducing manufacturing complexities.

The 17-4PH alloy has magnetic properties and good formability, making it applicable for electromagnetic and structural applications. With its wide range of benefits, 17-4PH stainless steel continues to be a favored choice in industries such as aerospace, defense, oil and gas, and medical technology, contributing to improved product performance, durability, and overall efficiency.

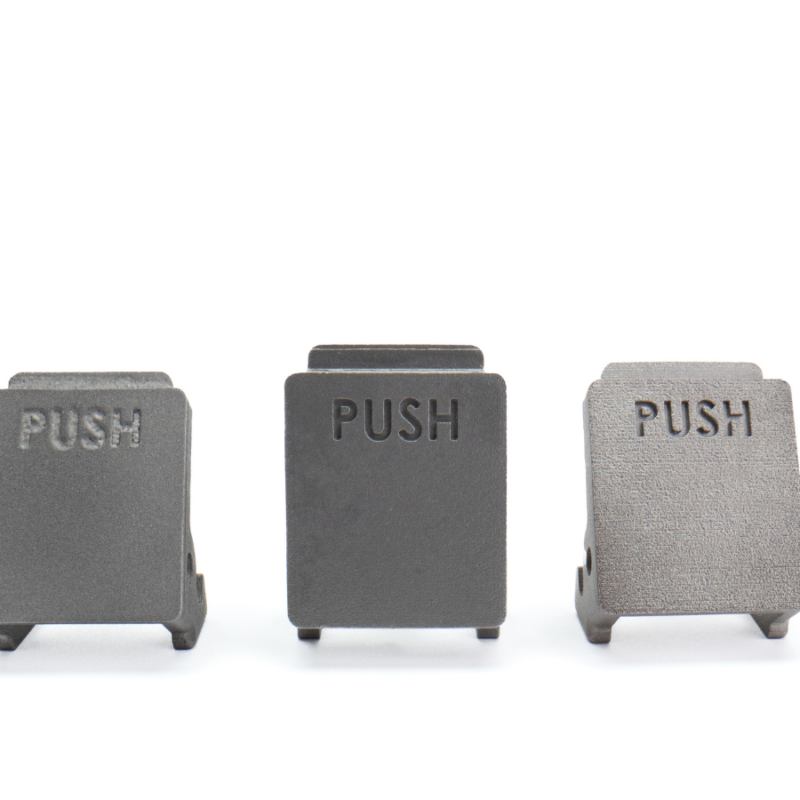

316L Stainless Steel

316L stainless steel offers a multitude of advantages, making it a highly sought-after material in various industries. Noted for its exceptional corrosion resistance, this low-carbon variant of the 316 stainless steel alloy is particularly well-suited for applications in aggressive environments, such as marine, chemical, and medical settings. Its resistance to pitting, crevice corrosion, and chloride-induced stress corrosion ensures prolonged product lifespan and reduced maintenance costs.

Furthermore, 316L stainless steel’s biocompatibility and non-reactivity with bodily fluids make it a preferred choice for medical implants and surgical instruments. Its ability to withstand high temperatures without significant degradation makes it valuable for applications in heat exchangers, industrial boilers, and other high-temperature environments.

The alloy’s malleability and formability make it easy to work with, allowing for intricate designs and versatile applications. Its aesthetic appeal, often retained through rigorous usage, also makes it a popular choice for architectural and design projects.

316L stainless steel is also environmentally friendly due to its recyclability and long-lasting nature, contributing to sustainable practices across industries. With its combination of durability, corrosion resistance, versatility, and environmental consciousness, 316L stainless steel continues to be a preferred material for critical applications, where performance, reliability, and longevity are paramount.

Titanium

Titanium, renowned for its remarkable strength-to-weight ratio and corrosion resistance, has become a prime choice in the realm of 3D printing. This versatile metal offers a range of benefits that make it ideal for various applications.

With its high strength, low density, and excellent biocompatibility, titanium is commonly used in aerospace, medical, and automotive industries.

In metal 3D printing, titanium is favored for its ability to produce lightweight yet durable parts. Its high strength-to-weight ratio allows for the creation of complex geometries that are both strong and lightweight. This makes it an excellent choice for applications where weight reduction is crucial, such as in aerospace components.

Furthermore, titanium’s corrosion resistance ensures that printed parts can withstand harsh environments without compromising their structural integrity. This makes it suitable for applications in marine environments or industries where chemical exposure is a concern.

In addition to its mechanical properties, titanium also exhibits excellent biocompatibility, making it a popular choice for medical implants and prosthetics. Its compatibility with the human body minimizes the risk of rejection or adverse reactions, making it a reliable and safe material for medical applications.

Overall, titanium’s strength-to-weight ratio, corrosion resistance, and biocompatibility make it one of the top metal additive materials in 3D printing. Its versatility and reliability have solidified its position as a preferred choice for various industries seeking high-performance and durable parts.

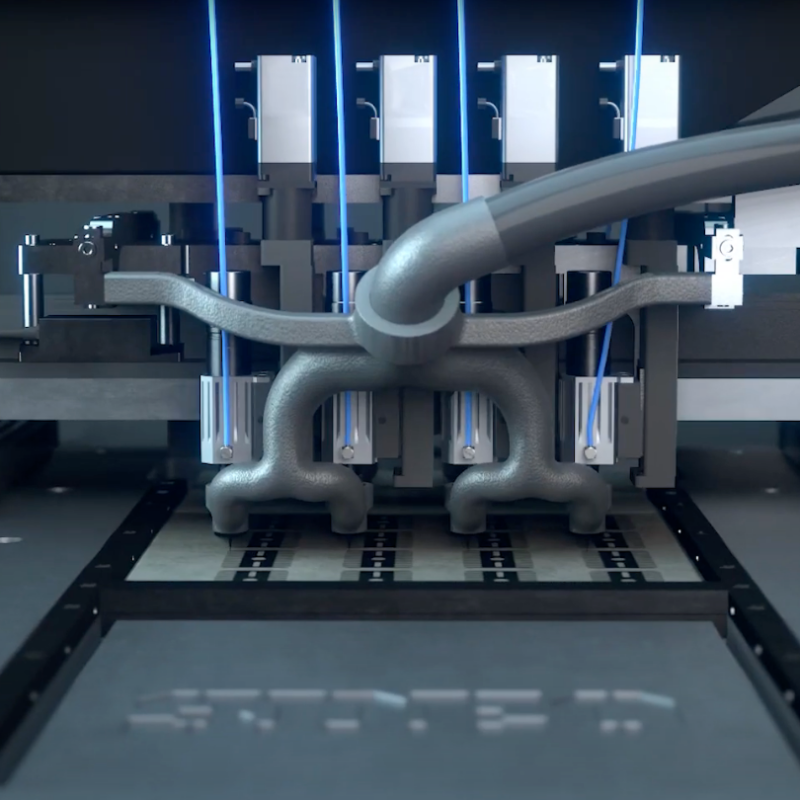

Copper

Copper is one of the top metal additive materials in the world of metal 3D printing, and for good reason. Its excellent electrical conductivity makes it ideal for a wide range of applications, from electrical components to heat sinks.

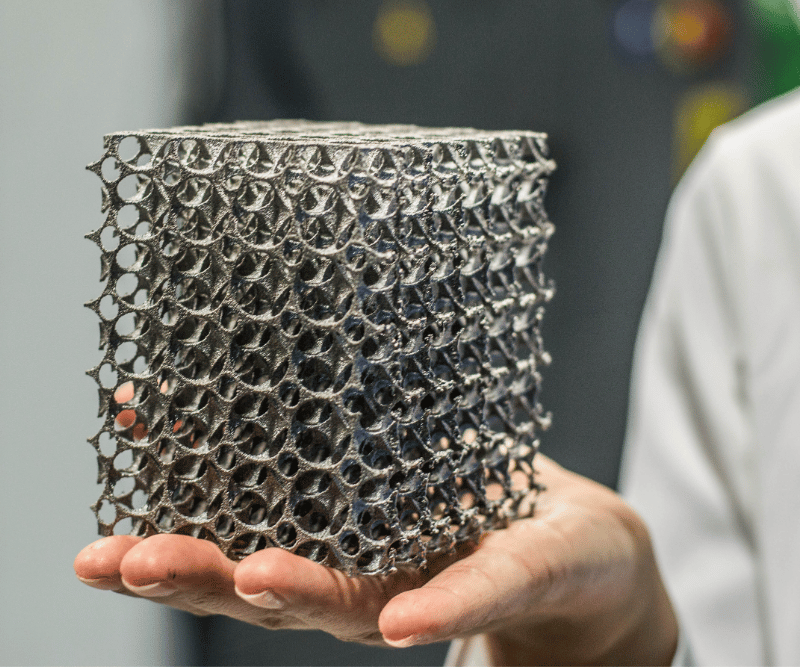

With copper 3D printing, you can create intricate designs with ease. The material is known for its high thermal conductivity, which means it can efficiently transfer heat away from components, making it perfect for creating efficient cooling systems. Its high strength and durability also make it suitable for manufacturing parts that need to withstand harsh environments.

One of the advantages of copper 3D printing is its ability to produce complex geometries that would be difficult to achieve using traditional manufacturing methods. This opens up a whole new world of possibilities for designers and engineers, allowing them to create unique and innovative products.

In addition to its functional properties, copper also offers an aesthetic appeal. Its reddish-orange hue adds a touch of elegance and sophistication to any design. So whether you’re looking to create functional prototypes or decorative pieces, copper 3D printing can help you bring your ideas to life.

Copper is a versatile and highly conductive material that has the potential to revolutionize the world of 3D printing. Its excellent electrical and thermal conductivity, combined with its strength and durability, make it an ideal choice for a wide range of applications. So why not explore the possibilities of copper 3D printing and see how it can transform your designs?

Nickel Alloys

These alloys are widely used in various industries due to their excellent mechanical properties and resistance to corrosion and high temperatures.

When it comes to metal Additive Manufacturing, nickel alloys have gained significant popularity. They provide superior strength, durability, and thermal stability, making them ideal for applications in aerospace, automotive, and medical sectors.

Whether you’re looking to create complex turbine blades or intricate surgical implants, nickel alloys have got you covered.

One of the most commonly used nickel alloys in 3D printing is Inconel. Its unique composition offers remarkable resistance to oxidation and creep deformation, making it suitable for extreme environments.

Another popular choice is Hastelloy, known for its exceptional corrosion resistance in aggressive chemical environments.

So, whether you’re pushing the boundaries of engineering or seeking innovative solutions in various industries, nickel alloys in metal Additive Manufacturing are a strong choice..

Partner with 3DEO Today

Learn more about the benefits of the metal additive materials that 3DEO has to offer and what may work best for your specific application. From 17-4PH and 316L stainless steels, to Pure Copper, partner with us to design, iterate, and create intricate metal components at scale. Let’s bring your ideas to life and revolutionize metal part production together!

Connect with our team of experts today.