Unlocking The Potential Of Metal 3D Printing Technology: Introducing 3DEO’s Advanced Intelligent Layering®

Metal 3D printing has the potential to transform manufacturing processes by offering you greater design freedom, flexibility, and accelerated product development. However, traditional methods have faced challenges in terms of quality and cost.

In this article, we explore 3DEO’s advanced technology, Intelligent Layering®, which combines CNC Machining and 3D printing to unlock the full potential of metal 3D printing.

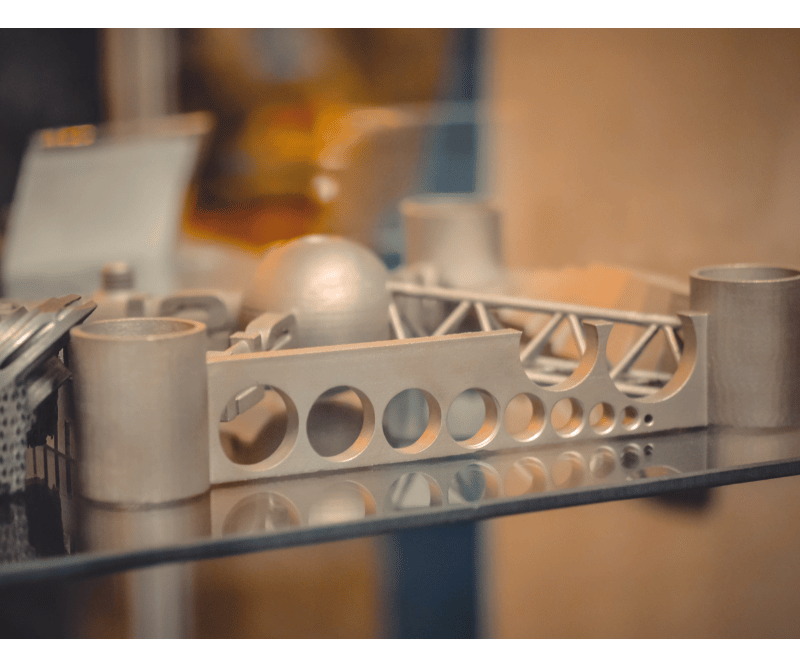

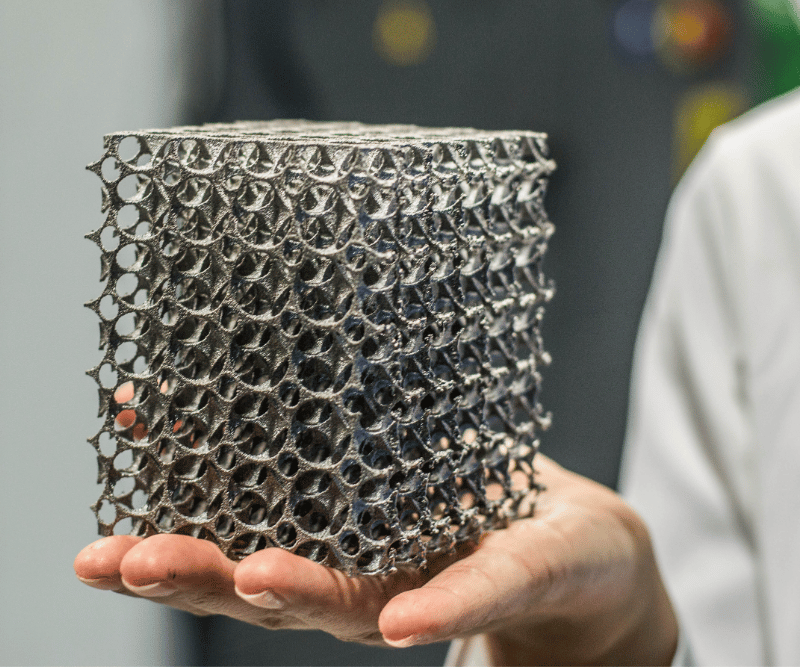

By utilizing a unique process that involves layering metal powder, binding it with a proprietary spray system, and cutting each layer with micro end mills, 3DEO’s technology enables the creation of complex geometries and minimizes layer lines.

This technology offers numerous advantages, including the ability to define multiple layers simultaneously, cut upward facing geometries in three dimensions, and automate the printing process for enhanced efficiency.

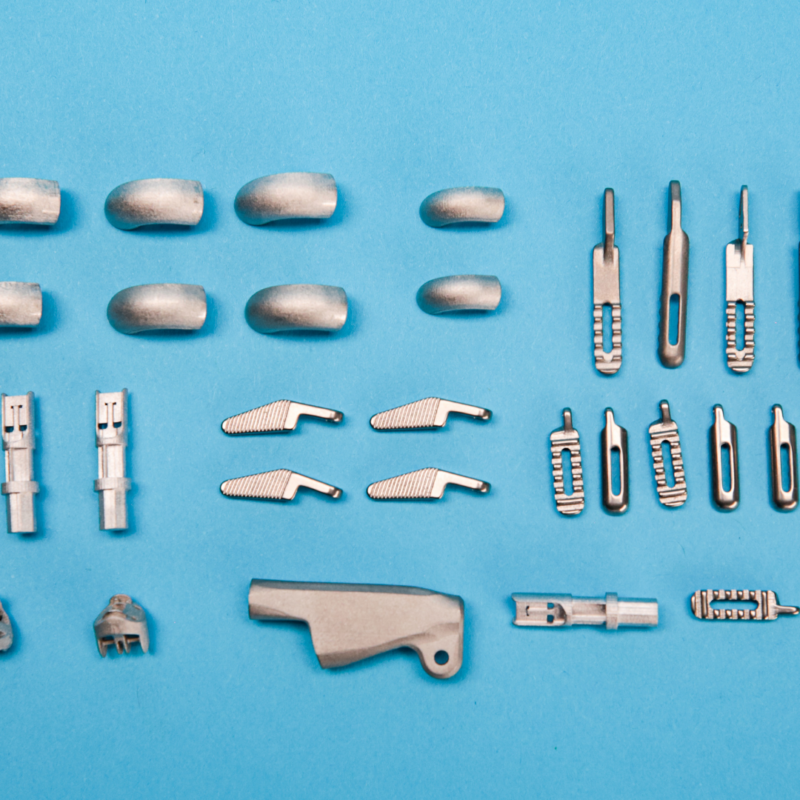

With its high precision, design flexibility, and reduced time to market, 3DEO’s technology is poised to drive innovation and competitiveness in the market, making metal 3D printing a viable option for manufacturing high-quality products at scale.

Key Takeaways

- 3DEO combines CNC Machining and 3D printing to unlock the potential of metal 3D printing.

- The printing process involves spreading metal powder, binding the powder, and cutting with micro end mills to build the entire part.

- 3DEO’s technology offers advantages such as the ability to define multiple layers simultaneously, cutting upward-facing geometries in three dimensions, and minimizing layer lines in the final print.

- The automation and efficiency of 3DEO’s technology increase production efficiency and reduce downtime between prints.

How Intelligent Layering® Works

The metal 3D printing technology developed by 3DEO combines CNC Machining and layer-by-layer printing to unlock the potential of metal 3D printing, offering design freedom, precision, and flexibility in creating complex geometries and high-quality metal parts.

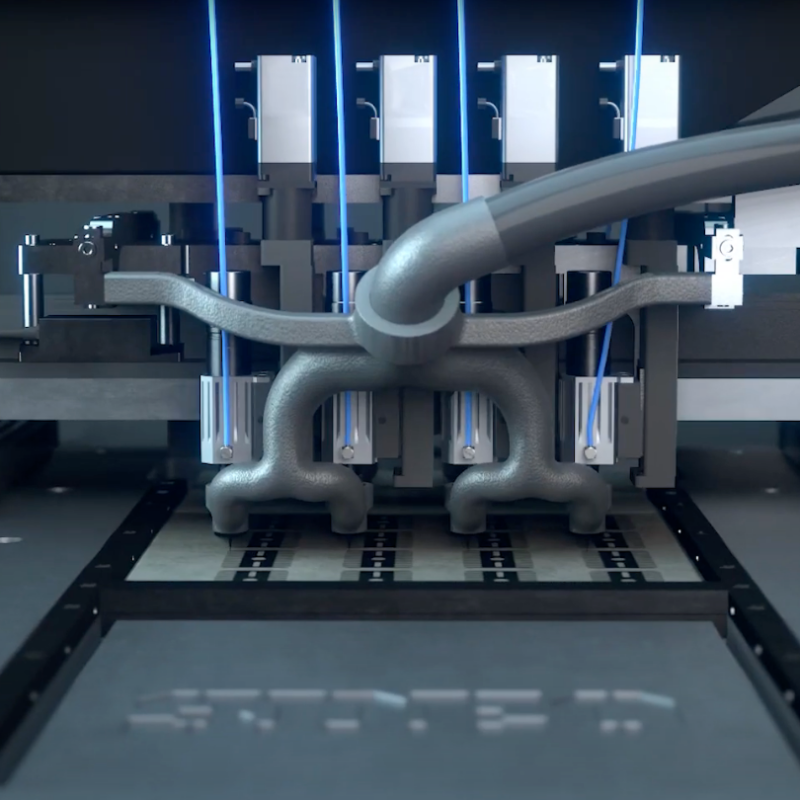

The printing process involves CNC Machining used on a layer-by-layer basis, with a build area of 81 square inches and 8 spindles operating at 60,000 rpm. The micron-level positional accuracy ensures precise and accurate printing.

The process consists of three core steps:

1.) Spreading metal powder, binding the powder using a proprietary spray system, and cutting with micro end mills. Metal powder is spread uniformly across the entire build area.

2.) The layer of powder is then bound using the spray system, which ensures uniformity and control over the depth of penetration.

3.) Finally, micro end mills are used to cut both internal and external features at each layer, allowing for the creation of complex geometries and minimal layer lines in the final print.

This technology offers advantages such as the ability to define multiple layers simultaneously, cutting upward facing geometries, and automation and efficiency in the printing process. It also provides high precision, design freedom, and flexibility, enabling faster product development and innovation in the market.

Advantages and Benefits

Advantages and benefits of 3DEO’s technology include:

– The ability to define multiple layers simultaneously

– The capability to cut upward-facing geometries in three dimensions

– The minimization of layer lines in the final print

By combining the strengths of CNC Machining and 3D printing, 3DEO’s intelligent layering technology offers:

– Design freedom and flexibility that surpasses traditional manufacturing methods

– Micron level positional accuracy

– A build area of 81 square inches

– The creation of complex geometries and customization through varying layer thickness

Carefully applied process automation increases production efficiency and reduces downtime between prints. The high-precision cutting and spraying operations deliver accuracy and repeatability, while ensuring uniformity and control over the depth of penetration, resulting in high-quality metal parts.

The advantages and benefits of 3DEO’s technology typically facilitate:

- Faster product development

- Reduced time to market

- Rapid prototyping

- Improved product quality

- Innovation in the market

Automation and Efficiency

Automation and efficiency are key features of Intelligent Layering. The printer automatically removes the build from the printer when complete and immediately starts the next job in the queue, resulting in increased production efficiency and reduced downtime between prints.

This automated process allows for a seamless transition between jobs, maximizing productivity and minimizing wasted time. By eliminating the need for manual intervention in the removal of completed builds, 3DEO’s technology streamlines the manufacturing process and enables a continuous workflow.

Additionally, first articles are produced using the exact same technology and processes as final production parts, supporting a swift and simple journey through the product development and regulatory processes.

As a result, companies using Intelligent Layering can optimize their manufacturing operations and respond to market demands more effectively.

Impact on Product Development

3DEO’s metal 3D printing technology revolutionizes product development by enabling faster time to market, facilitating rapid prototyping and iteration, improving overall product quality, and fostering innovation and competitiveness in the market.

Our state-of-the-art technology and innovative 3D printing methods reduces the time required for product development and allows for faster entry into the market.

This technology also enables rapid prototyping, allowing manufacturers to quickly test and refine their designs before final production.

By addressing the limitations of traditional manufacturing processes, such as tooling and machining, 3DEO’s technology improves the overall quality of the final product. The flexibility in both design and manufacturing techniques offered by metal 3D printing open up new opportunities for innovation and competitiveness in various industries.

Overall, 3DEO’s metal 3D printing technology has a significant impact on product development, driving efficiency, quality, and innovation.

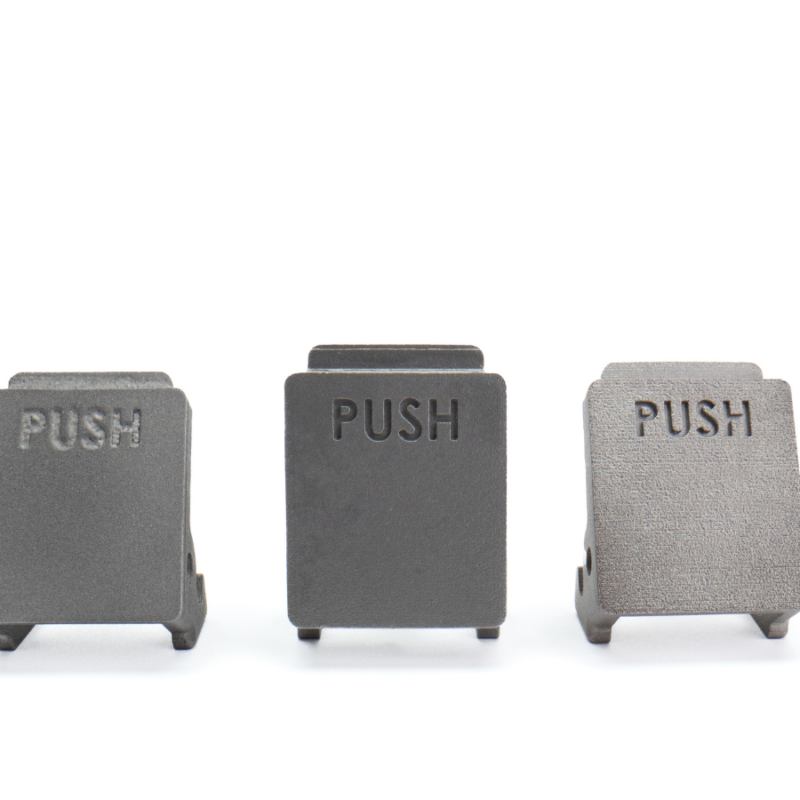

Learn More About Metal 3D Printing Technology

3DEO is revolutionizing metal 3D printing and sits at the forefront of this exciting and rapidly developing industry. To learn the latest on metal 3D printing technology, or for a metal 3D printing quote, sample parts kit, or any other information about our 3D metal printing services, contact 3DEO today.