Metal additive manufacturing (AM) isn’t a cure-all. It’s a strategic tool — and like any tool, it should be used where it gives you a real advantage.

At 3DEO, we don’t print parts just because we can. We print when geometry, performance, or speed make additive the better choice.

So how do you know when a part is worth printing?

Start with the Right Design Challenges

Additive shines when traditional methods hit their limits. If you’re facing one of these problems, it might be time to rethink the process:

✅ Your part has complex internal geometry

- Internal channels

- Cooling or fluid paths

- Hidden features that would be impossible to machine

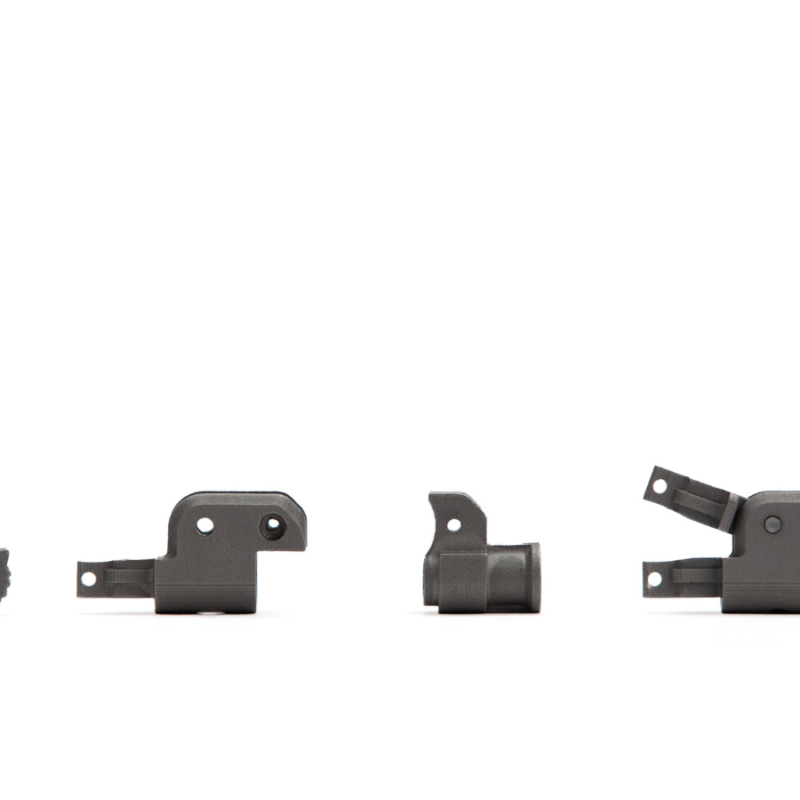

✅ You want to consolidate multiple parts into one

- Eliminate fasteners and welds

- Reduce assembly time

- Improve strength and performance

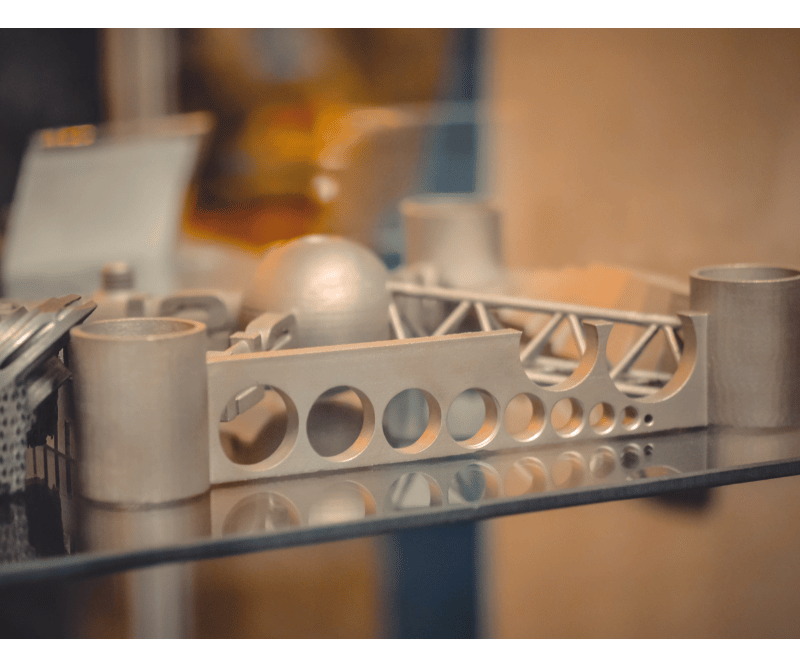

✅ You’re pushing for lighter weight without sacrificing strength

- Lattices, topology optimization, organic shaping — all tough for CNC

- AM allows efficient material placement only where needed

✅ You’re blocked by tooling lead times or cost

- Tooling quotes taking 8+ weeks?

- Additive lets you launch now and tool up later if needed

✅ You need fast, production-grade parts for a pilot run or launch

- AM isn’t just for prototypes — when done right, it delivers real, repeatable results

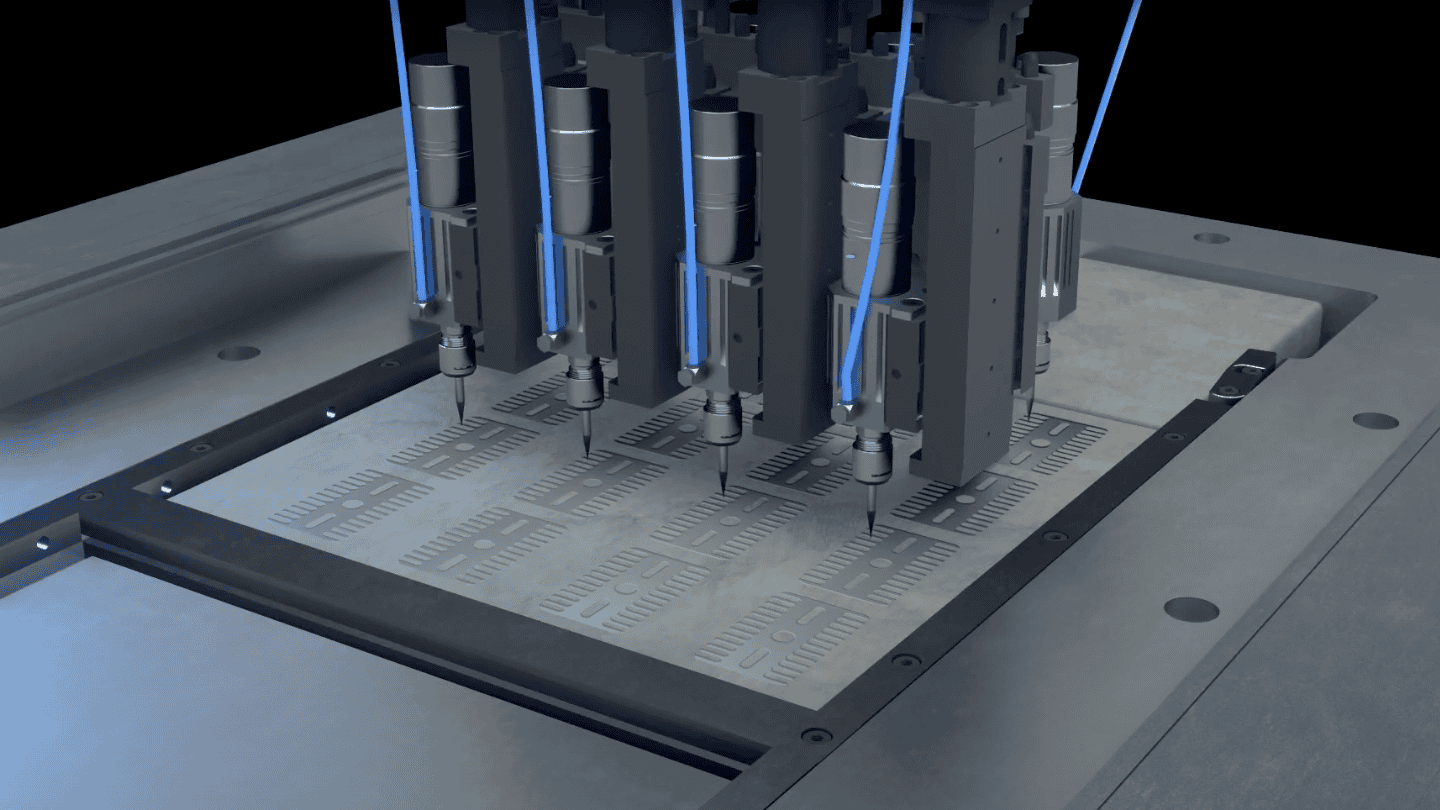

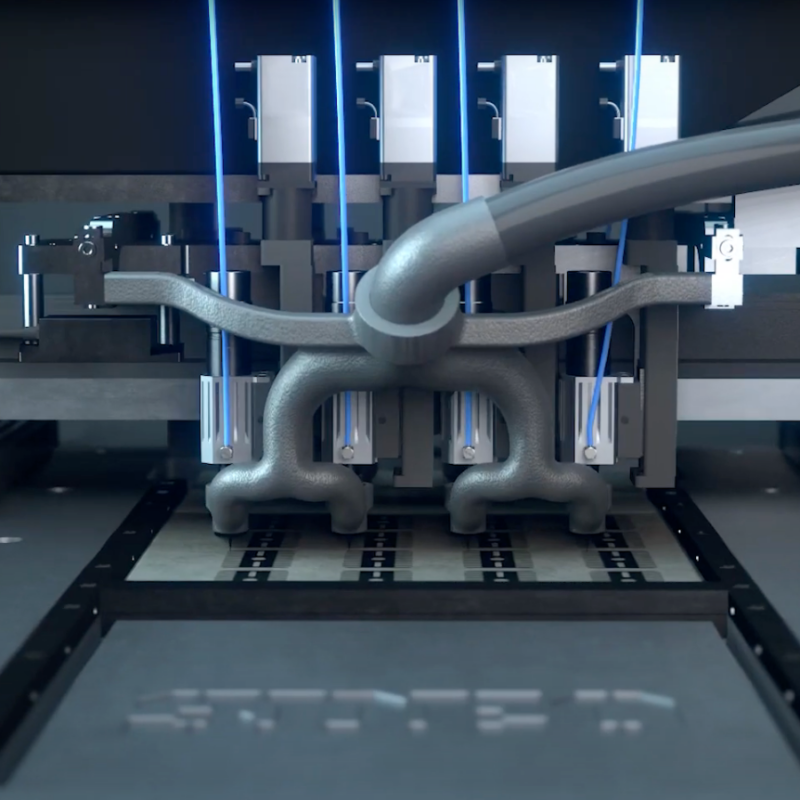

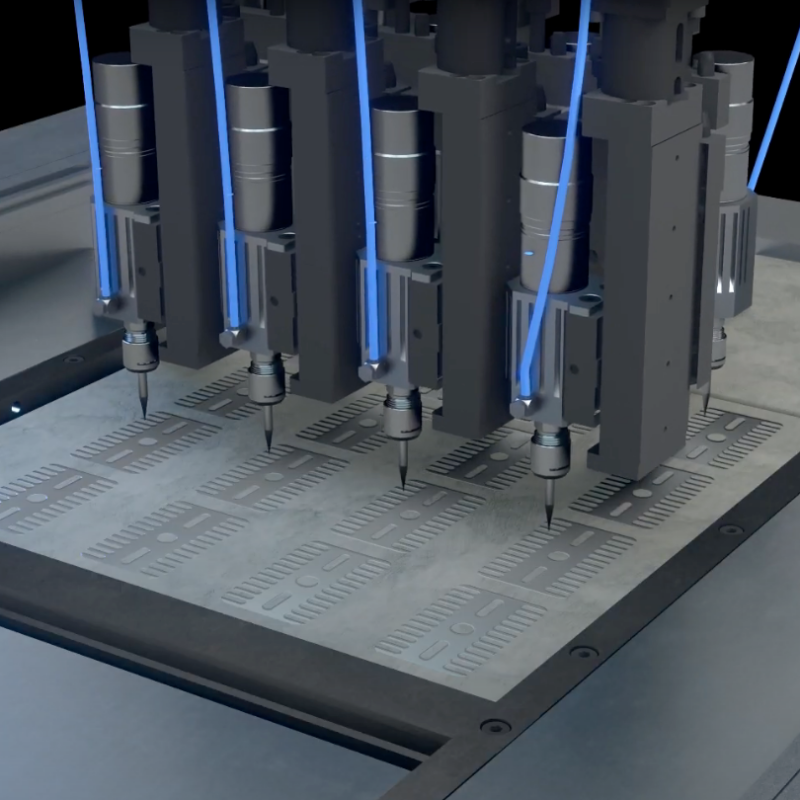

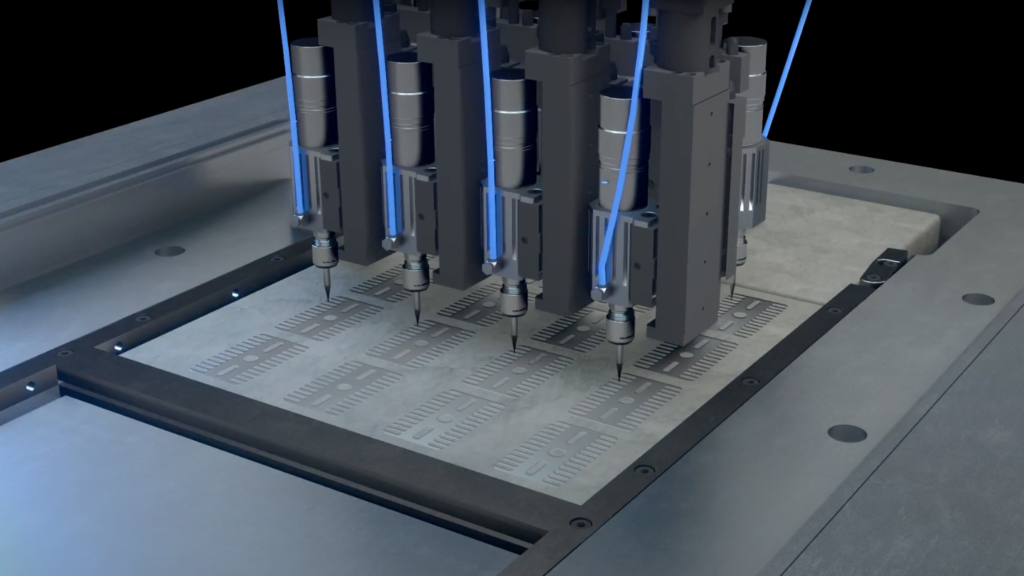

3DEO’s Intelligent Layering® Technology

When You Shouldn’t Print

Additive isn’t the right fit when:

- You’re making simple, high-volume parts with stable demand

- Tight tolerances and high surface finish are required without post-processing

- The part geometry doesn’t benefit from AM’s unique capabilities

- In these cases, MIM, CNC, or casting may still be more cost-effective.

That’s why we help you decide strategically — not just print blindly.

What Makes It Work: DfAM + Engineering Support

Additive unlocks the most value when you design for it — not just send over a CAD meant for machining.

At 3DEO, we partner with your team to:

- Run collaborative DfAM sessions

- Identify where performance can be improved

- Suggest geometry, weight, or consolidation optimizations

- Help you scale from prototype → bridge → production (even MIM)

You don’t have to know if your part is perfect for AM — we’ll help you figure that out.

🧠 Expert Tip: Performance ≠ Printability

Just because something can be printed doesn’t mean it should be. We use AM to improve performance — not just to replace other processes.

The Bottom Line

Additive manufacturing is about more than just printing — it’s about unlocking performance through design freedom.

So before you send your part to a shop that “just prints,” ask:

Will this design perform better because I used additive?

If you’re not sure — we’ll help you find out. Schedule a design review today.