The pace of technological growth and change is higher today than perhaps at any other point in human history. Blockchain, artificial intelligence, augmented/virtual reality—the list of potentially revolutionary breakthroughs now at our fingertips is long and growing. Of all the promising nascent technologies out there, however, none is closer to bringing real change to the way we live and work than additive manufacturing.

The pace of technological growth and change is higher today than perhaps at any other point in human history. Blockchain, artificial intelligence, augmented/virtual reality—the list of potentially revolutionary breakthroughs now at our fingertips is long and growing. Of all the promising nascent technologies out there, however, none is closer to bringing real change to the way we live and work than additive manufacturing.

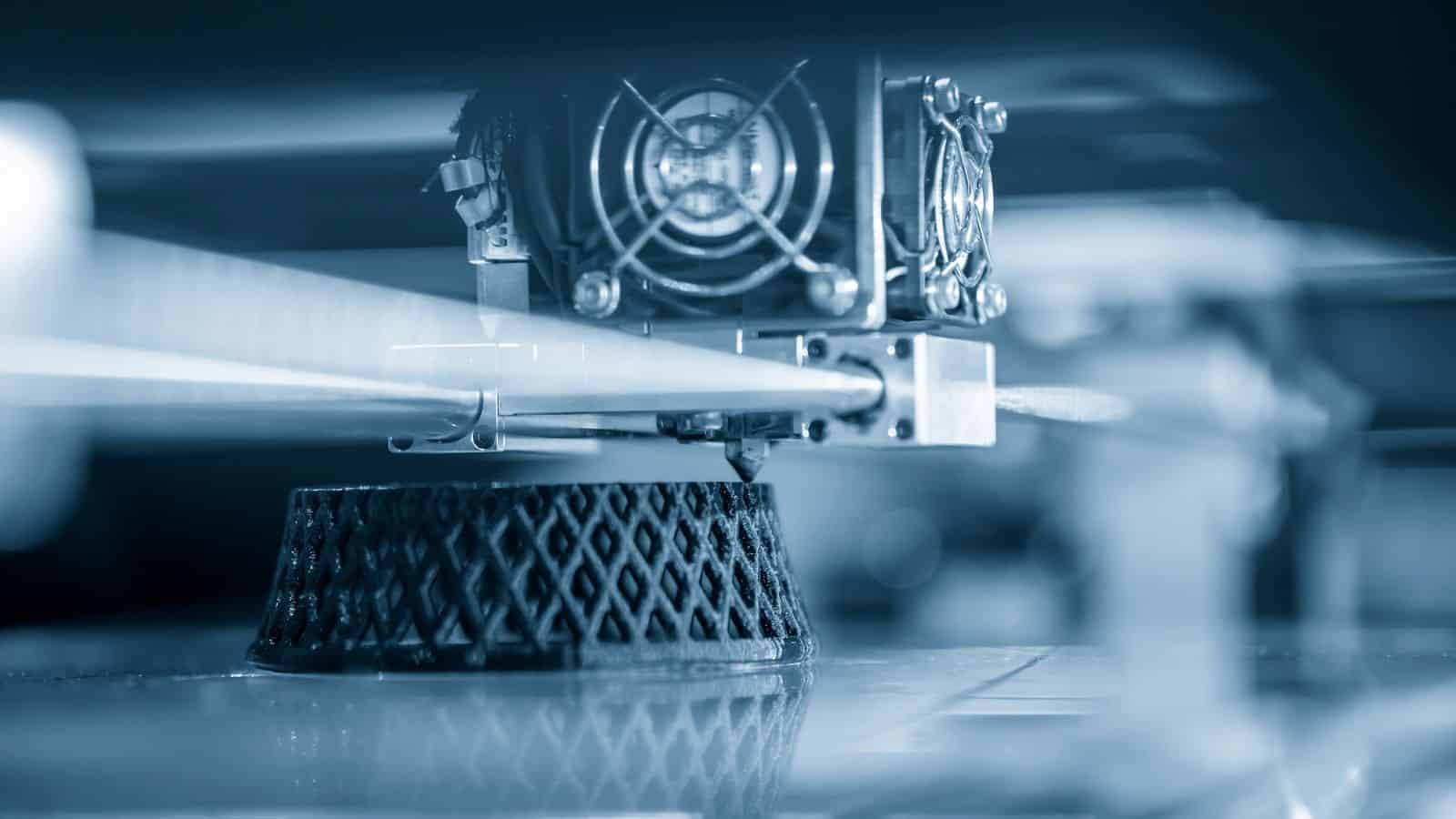

Otherwise known as metal 3D printing, this method of making things is almost literally the inverse of more traditional processes. Rather than molding an indeterminate hunk of raw materials into specific parts or components, additive manufacturing uses the specific volumes of material required to sculpt objects layer by layer.

This unique process comes with a host of advantages that expand the boundaries of feasibility in manufacturing. More practically, however, those unfamiliar with metal 3-D printing should note that its share of the total manufacturing market is growing rapidly.