The 2017 RAPID + TCT conference was held in Pittsburgh this week and featured new products and technologies from all the major players in the additive manufacturing industry. The Society of Manufacturing Engineers (SME) and TCT Magazine did a terrific job of producing the conference this year and ensured representation spanned the entire industry including 3D printing equipment manufacturers, parts suppliers, and supporting products such as scanners, design software and many others.

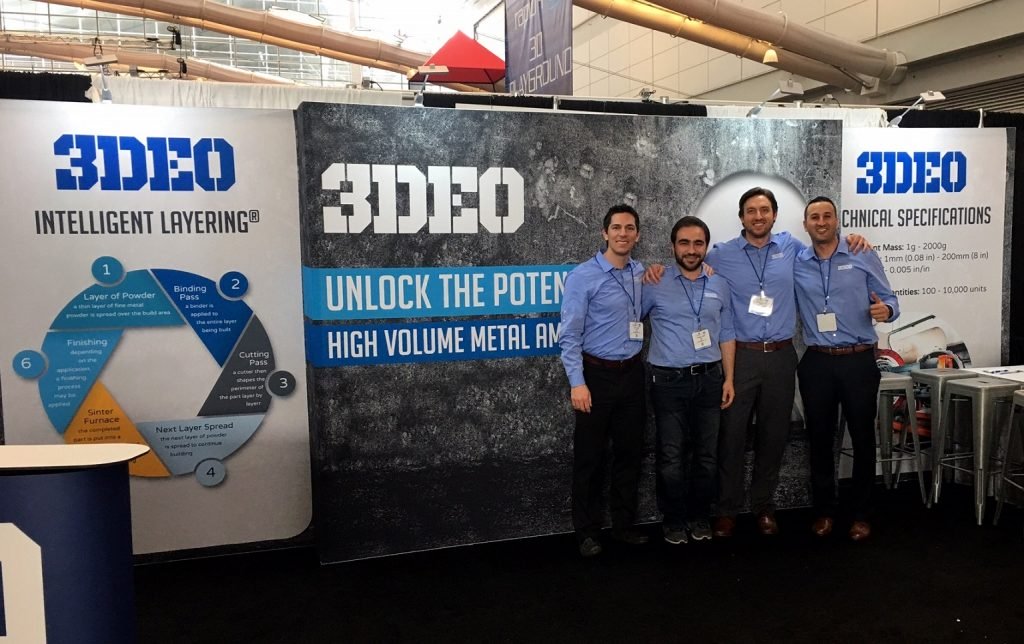

3DEO, an additive manufacturing parts supplier based in Los Angeles, attended RAPID + TCT as an exhibitor and showcased the latest advances to its proprietary technology by displaying 97% dense stainless steel parts. The new parts were particularly well received due to the high-quality surface finish achieved without any post processing. The 17-4PH stainless steel parts meet MPIF Standard 35, allowing 3DEO to provide parts into industries that currently accept the standard including (but not limited to) aerospace, automotive, industrial and medical.

Matt Petros, CEO of 3DEO and one of the inventors of the Intelligent Layering® process, presented at the Technology LaunchPad on Tuesday. The presentation covered the six steps to 3DEO’s Intelligent Layering® process and highlighted numerous real-world industry case studies. The presentation resulted in a flurry of positive attention from industry veterans and media alike, including this article on www.3dprintingindustry.com.

3DEO was also proud to be nominated as a semi-finalist for the TCT Innovation Award for new technology with its innovative Intelligent Layer® process.

Next year, RAPID + TCT will be held April 24-26 in Fort Worth, Texas. 3DEO has already reserved a booth and is looking forward to attending with even more innovations across available materials and build envelope.